MSIN0201BE/2002372V (1 of 6)

È

HYDRO-CUSHION

®

SERVICE CONNECTIONS

Ê

General

These service connections are required:

1. Piped inlets and outlets (cold water, hot water, “third” water,

reuse water, flushing supply water, Spray down and/or cool-

down water, steam, central liquid supply, peristaltic pump inlets,

compressed air inlet, vent, reuse and/or drain).

2. Electric power connections (for additional information see “EXTERNAL FUSE AND WIRE SIZES FOR

MILNOR

®

MACHINES” - MAEFUSE1AE).

Ê

Requirements for Piped Connections

Inlet pressures must be within the minimum/maximum range specified. Pressures outside of the specified

range may cause the machine to operate inefficiently or malfunction, and may damage machine components.

MACHINE DAMAGE—Valve bodies will be ruined if twisted and distorted.

☞

Hold the connection side of the valve with a wrench when connecting plumb-

ing.

MACHINE DAMAGE—Piping will be damaged if struck by tilting machine.

☞

Route piping to tilting machines carefully.

Machine Damage Hazards—Pumped chemical systems, if not properly in-

stalled, can cause corrosion damage.

☞

See the reference manual for precautions and additional information before

making any chemical connections.

Ë

Piped Inlet/Outlet Specifications

—The piped inlet and outlet requirements are as follows (see dimen-

sional drawings for the size and location of connection points):

Ï

Piped Inlets

Description of Connection

Source Requirements

Piping Specifications

Cold water inlet

See dimensional drawing

for size.

30 - 65 PSI

(2.10 - 4.57 kilogram/centimeter)

Pipe material per plumbing code

(see “Piped Inlet Precautions,”

in this section)

Hot water inlet

“Third” water inlet

Reuse water inlet

Steam inlet

See dimensional drawing for size.

30 - 115 PSI

(2.10 - 4.57 kilogram/centimeter)

Pipe material per plumbing code

(see “Steam Precautions”,

in this section

Flushing water for supply injector

(Divided cylinder, 52", and 72"

open pocket non-tilt machines only)

See dimensional drawing for size.

30 - 65 PSI

(2.10 - 4.57 kilograms)

Pipe material per plumbing code

(see “Flushing Water Connections,”

in this section)

Peristaltic pump inlets

1/2" NPT

Flexible tubing as specified

by chemical supplier

(see “Peristaltic Pump

Connections,” in this section)

Central liquid supply

1/2" and 3/8" NPT

Flexible tubing as specified

by chemical supplier

Compressed air inlet

See dimensional drawing for size.

85 - 115 PSI

(5.97 - 8.08 kilogram/centimeter)

Pipe material per plumbing code

Ë

Outlet Specifications

—The outlet requirement is as follows. See dimensional drawings for connection sizes

and locations.

Ï

Outlets

Description of Connection

Destination Requirements

or Description

Piping Specifications

Drain to reuse

(if so equipped)

or

Drain to sewer

Provide a centrally located open

trench, with a minimum slope of

1/8" per foot (10 mm per meter)

(See dimensional drawing)

Do not connect dump valves to

drain. Attach short pieces of hose to

dump valves to control splashing.

Do not immerse ends of hoses.

(see “Drains” in this section)

Vent

See dimensional drawing

Flexible tubing supplied by others

(see “Vents” in this section)

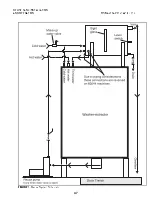

IT IS NORMAL FOR THE VEGETABLE FIGER

GASKET ON THIS SHELLFRONT TO LEAK

SLIGHTLY WHEN THE MACHINE IS FIRST

COMMISSIONED. IT SHOULD STOP LEAKING

AFTER THE FIRST FEW LOADS ARE PROCESSED.

Î

FIGURE 1

(MSIN0201BE)

Î

All Machines

35

Summary of Contents for 42044SR2

Page 2: ......

Page 4: ......

Page 8: ......

Page 9: ...Installation 1 5 ...

Page 37: ...Î FIGURE 8 MSIN0301AE Î Vibration Switch Î FIGURE 9 MSIN0301AE Î 60 Staph Guard 33 ...

Page 51: ...586DA4 BUecU CicdU CSXU QdYS B5EC5 D1 9 CD1 1D9 1 4 5B1D9 C9 1 15 1F _V 47 ...

Page 53: ...Dimensional Drawings 2 49 ...

Page 54: ......

Page 55: ...51 ...

Page 56: ...52 ...

Page 57: ...53 ...

Page 58: ...54 ...

Page 59: ...55 ...

Page 60: ...56 ...

Page 61: ...57 ...

Page 62: ...58 ...

Page 63: ...59 ...

Page 64: ......

Page 65: ...61 ...

Page 66: ...62 ...

Page 67: ...63 ...

Page 68: ...64 ...