Ë

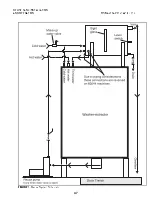

Vent

— Because of the relatively small volume of exhaust air produced by a washer-extractor (versus a dryer, for

example) it is almost never necessary to vent a washer-extractor to the outside. One possible exception is with

Staph-Guard

®

models, for sanitary reasons. Note, however, that even without exterior venting, the vent mechanism

on Staph-Guard

®

machines will draw air in from the clean side and exhaust it to the soil side, providing a barrier

wall has been properly installed in accordance with the machine dimensional drawing.

Ê

Precautions for Electrical Connections

ELECTROCUTION HAZARD—Contact with high voltages can kill or seriously

injure you.

☞

All electrical connections must be made by a competent electrician.

Ë

When Making Electrical Power Connections

1. Connections must be made by a competent electrician.

2. See fuse and wire sizing information in the schematic manual and on the machine nameplate.

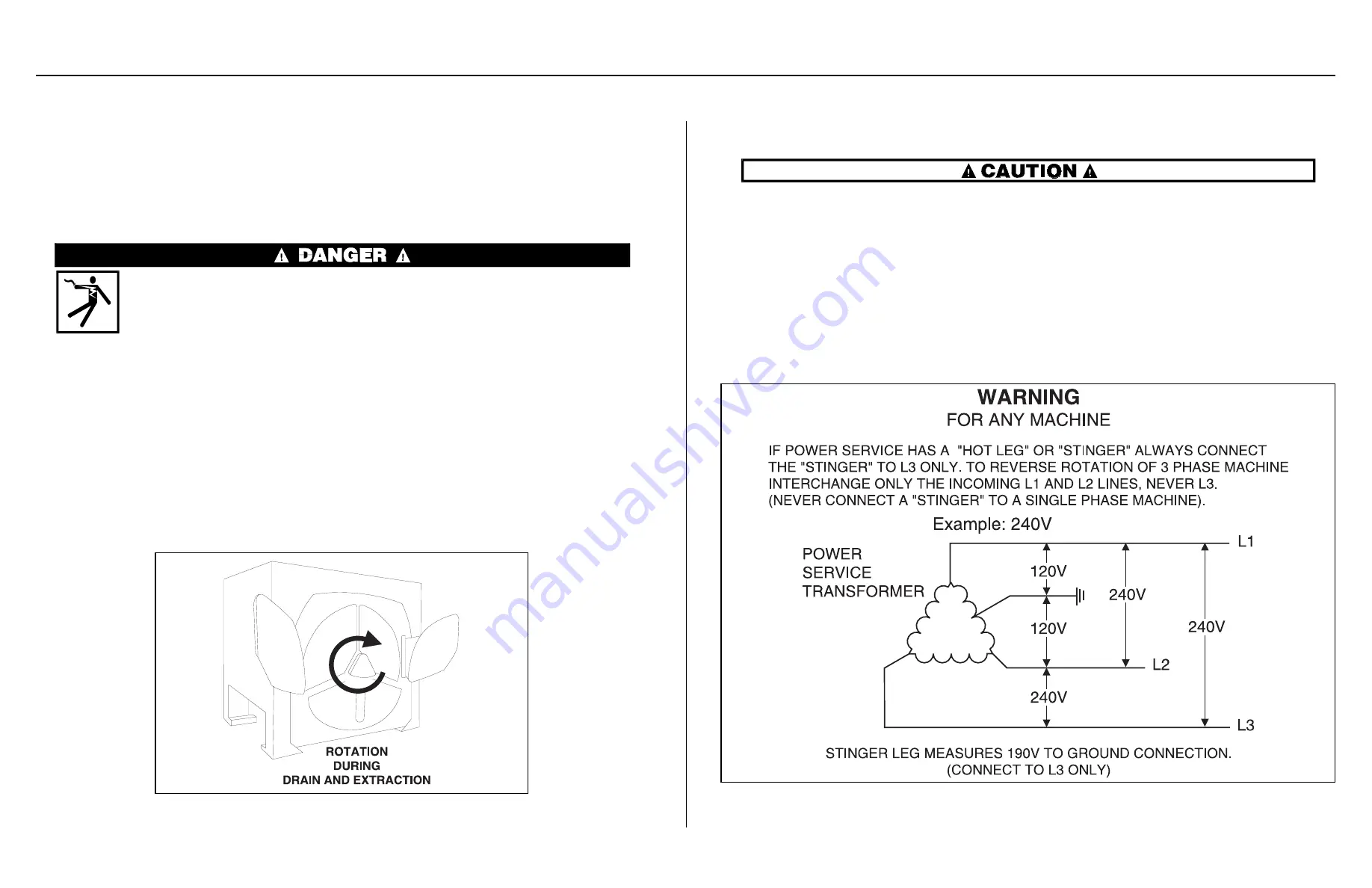

3. “Stinger leg,” if any, must be connected to terminal L3 only.

4. Make power and liquid supply electrical connections within junction boxes on rear of machine.

5. Use only Bussman Fusetron FRN (up to 250V), FRS (up to 600V) or similar lag fuses. The nameplate fuse

sizes must not be applied to standard fuses.

6. See nameplate and wire sizing information in the schematic manual for fuse and wire sizes. For wire runs of

more than 50 feet (15.24), increase by one wire size per each additional 50 feet (15.24).

7. Verify all motor rotation (see the Mark II washer-extractor reference manual for further information).

Ê

Electric Power Connections

Voltage fluctuations of more than 10% above or below the specified voltage for the machine

are extremely detrimental to electrical components, especially motors.

☞

Correct any such conditions prior to commissioning the machine.

The customer must furnish a remotely mounted disconnect switch with lag type fuses, circuit breakers, and

wiring between the electrical service box and the junction box on the machine. The sizes of these fuses and wires,

along with the motor fuses supplied with the machine, depend on the machine voltage. See fuse and wire sizing

information in the schematic manual and on the machine nameplate. If machine has been in storage or transit for

several months, the time relay(s) may not time out correctly the first time. After a few operations they will correct

themselves. Do not condemn them until they are allowed to operate several times.

Î

FIGURE 12

(MSIN0201BE)

Î

Cylinder Rotation (Viewed from front)

Î

FIGURE 13

(MSIN0201BE)

Î

Electrical Service Example

40

Summary of Contents for 42044SR2

Page 2: ......

Page 4: ......

Page 8: ......

Page 9: ...Installation 1 5 ...

Page 37: ...Î FIGURE 8 MSIN0301AE Î Vibration Switch Î FIGURE 9 MSIN0301AE Î 60 Staph Guard 33 ...

Page 51: ...586DA4 BUecU CicdU CSXU QdYS B5EC5 D1 9 CD1 1D9 1 4 5B1D9 C9 1 15 1F _V 47 ...

Page 53: ...Dimensional Drawings 2 49 ...

Page 54: ......

Page 55: ...51 ...

Page 56: ...52 ...

Page 57: ...53 ...

Page 58: ...54 ...

Page 59: ...55 ...

Page 60: ...56 ...

Page 61: ...57 ...

Page 62: ...58 ...

Page 63: ...59 ...

Page 64: ......

Page 65: ...61 ...

Page 66: ...62 ...

Page 67: ...63 ...

Page 68: ...64 ...