Chapter 3. Routine Maintenance

PELLERIN MILNOR CORPORATION

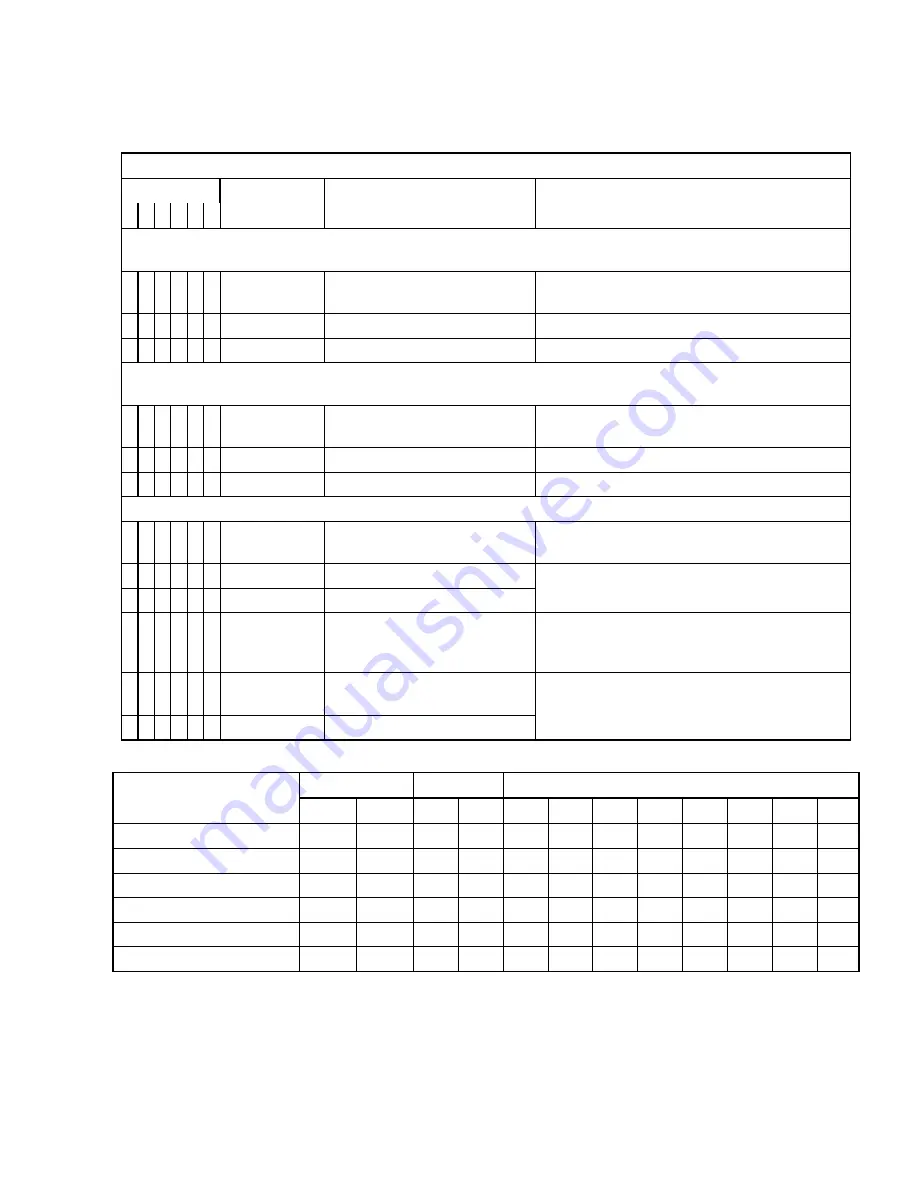

Table 6: Bearings and Bushings. See

Apply grease to these components to prevent damage.

Mark

1

2

3

4

5

6

Do this each

Component

More Data. See also

“Lubricant Identification and Procedures”

Grease plate 01 10025X for bearing housing. Use this data if your machine has this grease plate. See

and

x

200 hours

seal

Add 0.18 oz. (5.4 mL) of grease EPLF2

(

x

200 hours

rear bearing

Add 0.3 oz. (9 mL) of grease EPLF2

x

200 hours

front bearing

Add 0.6 oz. (18 mL) of grease EPLF2

Grease plate 01 10025Y for bearing housing. Use this data if your machine has this grease plate. See

and

x

200 hours

seal

Add 0.12 oz. (3.6 mL) of grease EPLF2

(

x

200 hours

rear bearing

Add 0.3 oz. (9 mL) of grease EPLF2

x

200 hours

front bearing

Add 0.3 oz. (9 mL) of grease EPLF2

Other Grease Ports

x

200 hours

hydraulic door bushings

See

. Add 0.06 oz. (1.8 mL) of

grease EPLF2 (

x

200 hours

door latch plunger

x

200 hours

door open plunger

See

. Apply stick DE3 (

surface.

x

200 hours

lower pivot for hydraulic

cylinders—one place, each

side

See

. Add 0.06 oz. (1.8 mL) of

grease EPLF2 (

none

upper pivot for hydraulic

cylinders

none

front tilt pivot

See

. No grease maintenance

necessary.

Table 7: Motor Grease Schedule. Use the data in

to complete this table.

Interval

Quantity

Dates When Grease is Added

Motor Identification

(example: main drive)

Years

Hours

fl oz

mL

.

26

Summary of Contents for 48040F7B

Page 2: ......

Page 4: ......

Page 5: ...English 1 1 ...

Page 6: ......

Page 8: ...Applicable Milnor products by model number 48040H7N 68036H5N 4 ...

Page 51: ...Deutsch 2 47 ...

Page 52: ......

Page 54: ...Gilt für die Milnor Produkte mit den folgenden Modellnummern 48040H7N 68036H5N 50 ...

Page 99: ...中国的 3 95 ...

Page 100: ......