Summary of Contents for 48040M7K

Page 2: ......

Page 8: ......

Page 9: ...Safety 1 5 ...

Page 43: ...Installation 2 39 ...

Page 56: ......

Page 57: ...Drive 3 53 ...

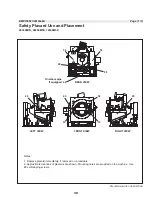

Page 59: ...Drive Components and Belt Installation PELLERIN MILNOR CORPORATION Figure 2 Detailed views 55 ...

Page 93: ...Frame and Tilt 4 89 ...

Page 101: ...Hydraulic Assemblies 5 97 ...

Page 110: ......

Page 111: ...Door Assemblies 6 107 ...

Page 125: ...Water and Steam 7 121 ...

Page 137: ...Chemical 8 133 ...

Page 142: ......

Page 143: ...Control and Sensing Assemblies 9 139 ...

Page 149: ...Dimensional 10 145 ...

Page 150: ......

Page 151: ...147 ...