Chapter 3. Routine Maintenance

PELLERIN MILNOR CORPORATION

Apply grease as follows:

1. Operate the machine or use manual functions to operate the motor until it is warm.

2. Remove power from the machine.

3. If the motor has grease drain plugs, remove them. See

caution statement

24

.

4. Add grease EM (

Table 10

) with the motor stopped. If the motor with the nameplate in

Figure

6

operates at 60 Hz, the specified grease quantity for each grease fitting is 0.65 fl oz (18.4

mL).

5. If the motor has a grease drain plugs, operate the machine or use manual functions to operate

the motor for two hours. Replace the drain plug.

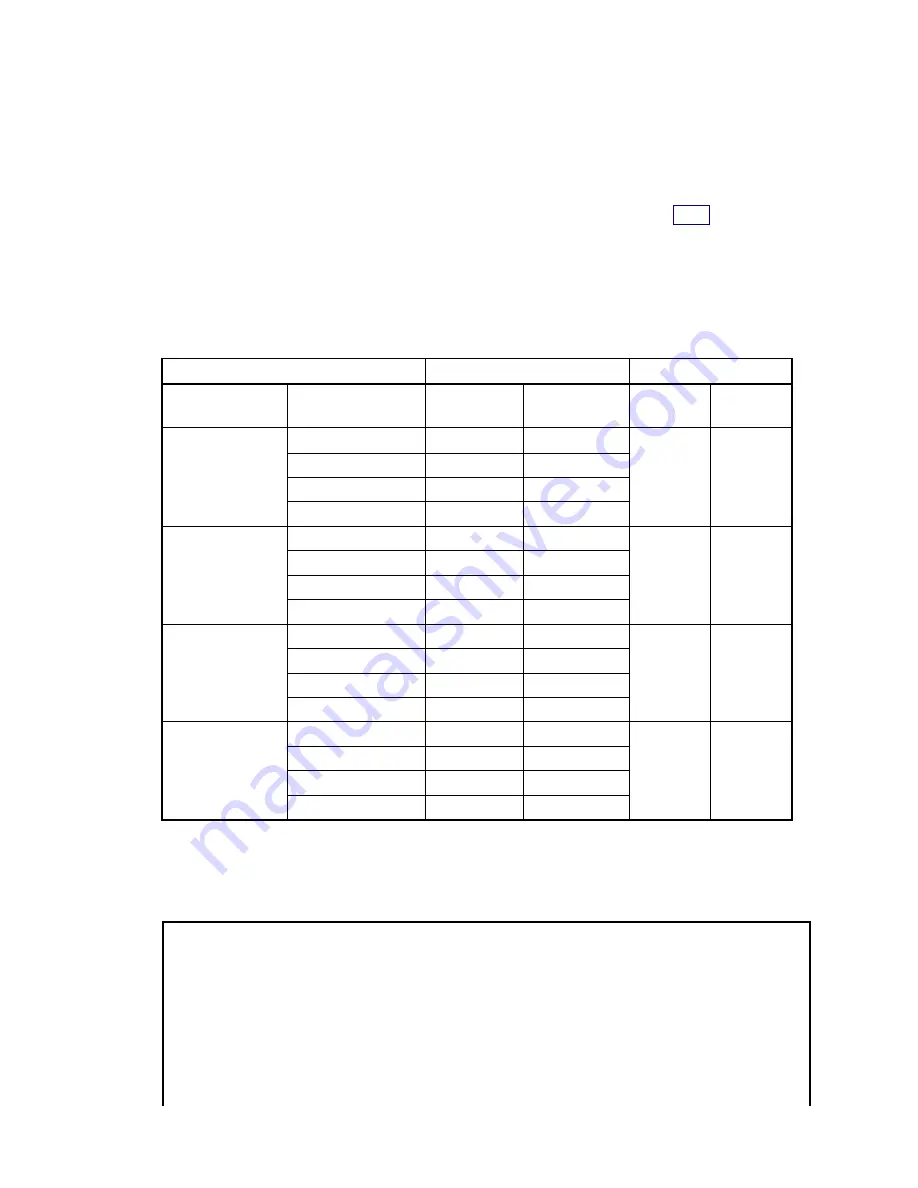

Table 11: Motor Grease Intervals and Quantities. Use grease EM (

Table 10

)

On Motor Nameplate (see

Figure 6

)

Interval

Quantity

NEMA (IEC)

Frame Size

RPM Less Than

or Equal To

Years

Hours

Fluid

Ounces

mL

900

5.5

11000

1200

4.5

9000

1800

3

6000

Up to 210 (132)

3600

1.5

3000

0.34

9.5

900

4.5

9000

1200

3.5

7000

1800

2.5

5000

>210 to 280 (132

to 180)

3600

1

2000

0.65

18.4

900

3.5

7000

1200

3

6000

1800

2

4000

>280 to 360 (180

to 200)

3600

0.5

1000

0.87

24.6

900

2.5

5000

1200

2

4000

1800

1

2000

>360 to 5000

(200 to 300)

3600

0.5

1000

2.23

63.2

3.1.5.

Maintenance Components—Machines and Controls Group

[Document BIUUUM10]

Supplement 1

How to Examine Belts and Pulleys

Examine belts and pulleys as explained below.

With power removed:

• Look for dirt, dust, oil, and grease. Remove contamination.

• Look for belt damage as shown in

Figure 7

.

• Look for worn pulleys as shown in

Figure 7

.

With the machine in operation—Do not touch the machine.

Look and listen:

30

Summary of Contents for 60 Series

Page 2: ......

Page 4: ......

Page 5: ...English 1 1 ...

Page 6: ......

Page 8: ...Applicable Milnor products by model number 60044SP2 60044SP3 60044WP2 60044WP3 4 ...

Page 47: ...Deutsch 2 43 ...

Page 48: ......

Page 50: ...Anwendbare Milnor Maschinen der Modelle 60044SP2 60044SP3 60044WP2 60044WP3 46 ...