Chapter 3. Routine Maintenance

PELLERIN MILNOR CORPORATION

• A belt can have some vibration and not cause damage. It is necessary to correct this

condition only if the vibration is large.

• A belt must have sufficient tension that there is no slippage on the pulley during operation.

If slippage occurs, you can usually tell from the noise.

About Component Replacement and Tension Adjustment

—Correct adjustment is very

important to the service life of components and operation of the machine. Your Milnor dealer

can do this work. If you know how to do this work (for example, correctly align belts and

pulleys), and you want to do it, speak to your dealer or Milnor for part numbers. Replace worn

components before you make tension adjustments.

• Machines that use rods with full threads and nuts to hold the position of the motor

base—Turn the nuts on the rods as necesary to adjust tension. Tighten the nuts.

• Machines that use a spring to hold tension on the motor base—Use the metal tube supplied

with the machine. Put the tube on the rod that the spring is attached to or remove the tube to

increase or decrease tension. Replace the spring if necessary.

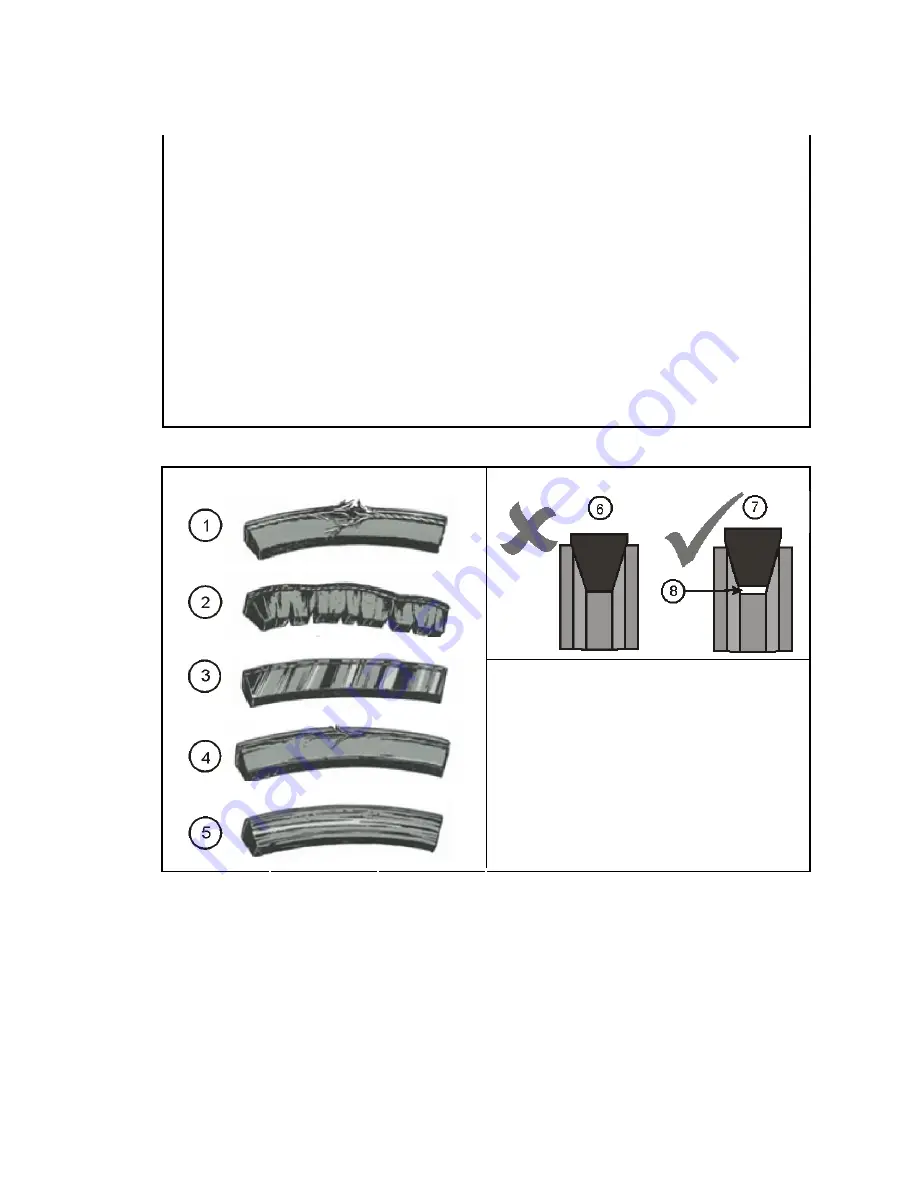

Figure 7: Belt and Pulley Conditions To Look For. See

Supplement 1

.

Types of Belt Damage

How to Find a Worn Pulley

Legend

.

1.

Broken cord—damage from a sharp object.

2.

Cracks—belt is too large for the pulley.

3.

Shiny side walls—oil or grease on belt.

4.

The belt layers disconnect—Oil or grease.

5.

Bands on side walls—dirt, particles.

6.

Incorrect: The pulley is too worn.

7.

Correct: The belt only touches the side

walls. You can put a thin strip of paper into

the space between the belt and the pulley.

8.

Space

31

Summary of Contents for 60 Series

Page 2: ......

Page 4: ......

Page 5: ...English 1 1 ...

Page 6: ......

Page 8: ...Applicable Milnor products by model number 60044SP2 60044SP3 60044WP2 60044WP3 4 ...

Page 47: ...Deutsch 2 43 ...

Page 48: ......

Page 50: ...Anwendbare Milnor Maschinen der Modelle 60044SP2 60044SP3 60044WP2 60044WP3 46 ...