MSSM0303AE/8451BV (1 of 5)

È

MAIN BEARING AND SEAL REPLACEMENT

FOR DIVIDED CYLINDER MACHINES

This section applies to the front and rear cylinder shaft bearings of all divided cylinder machines (Rapid Load,

Staph-guard

®

, dye machines, etc.). It does not apply to jackshaft bearings, idler shaft bearings or bearings on open

pocket machines.

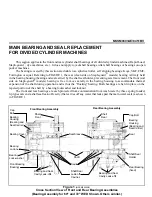

The bearings covered by this section are double row, spherical roller, self aligning bearings; Koya, SKF, FMC,

Torrington or equal. Referring to FIGURE 1, the rear (clean side on Staph-guard

®

models) bearing is firmly held

in the bearing housing (bearing and seal carrier) by the shaft seal holder, preventing axial movement. The front (soil

side on Staph-guard

®

models) bearing is free to move axially in the bearing housing to accommodate thermal

expansion of the shaft during operation and is thus the “floating” bearing. Both bearings are held in place on the

tapered portion of the shaft by a bearing lockwasher and locknut.

The front and rear bearings are each protected from contamination from wash water by three spring loaded,

lip type seals and a shaft seal leak-off cavity (that carries off any water that leaks past the main water seals) as shown

in FIGURE 1.

Access to the bearings and seals for lubrication is provided by the various grease passages. Excess lubricant is

excreted through the bearing and seal cavity leak-offs as shown on FIGURE 1. The bearings and seals must be

lubricated regularly and the leak-off cavities flushed out periodically through the plugged cleanout connections, in

strict accordance with the preventive maintenance procedures elsewhere.

If bearing replacement becomes necessary due to wear, it is essential that the bearings and seals are replaced.

Seal replacement requires removal of the bearing housing and seal sleeve. (In rare instances where the seals are

known to be in good condition, it is not necessary to remove the bearing housing, seals or seal sleeve when a bearing

is replaced.) A pulling fixture is required to remove the bearing housing. A set of guide rods, a seal sleeve

setting fixture and a bearing setting fixture are required for reinstallation of the housing. These tools are

available for rental or purchase from the Milnor

®

factory and are pictured elsewhere in this section. Contact the

factory two weeks in advance of repairs, when ordering these tools.

This maintenance is performed in the following order:

1. Remove old bearing(s). When removing both bearings, remove the front (soil side) bearing first.

2. Remove bearing housings, seal sleeves, and seals.

3. If both bearings were removed, install the bearing housing, seal sleeve, seals, and new bearing on the rear

(clean side).

4. Install the bearing housing, seal sleeve, seals, and new bearing on the front (soil side).

5. Tighten bearing(s).

See the Main Bearing Assembly drawing for your machine for bearing component part numbers.

Ê

Removing the Bearing (Front or Rear)

1. Loosen, then remove the main drive belts and

cylinder shaft pulley (if applicable) by lowering the

drive base with the jacking bolts. Do not attempt to

pry belts off with a pry bar or by rolling the sheave.

Remove the bearing cover (or shaft seal holder) to

expose the bearing.

2. Bend back the locking tang on the bearing lock-

washer then remove the locknut and lockwasher.

3. The center tapped hole in the shaft end is an oil pas-

sage through which oil may be forced between the

tapered shaft and the bearing inner race. Install a

pipe fitting into this tapped hole as shown in figure

to the right. Using a “Porto-Power” or similar hand

operated hydraulic pump, force fluid into the pas-

sage. Pump hard to build up fluid pressure. This

pressure will cause the inner race to expand slight-

ly; just enough to free the tapered surfaces and

allow the bearing to slip off easily. If the bearing is

not readily removed, remove the front water level

Shaft Seal

Holder

Seal

Bearing

Housing

(Bearing and

Seal Carrier)

Cap Bolt

Shaft Seal

Leak-off

Cavities

Bearing and Seal

Cavity Leak-offs

Bearing and Seal

Cavity Leak-offs

Front Bearing

(floating)

Bearing

Lock-washer

Cap

Bolt

Bearing

Lock-nut

Seals

Bearing Cover

Shaft

Bearing

Housing

(Bearing and

Seal Carrier)

Shell

Rear

Seal Sleeves

Rear Bearing

(fixed)

Rear Bearing Assembly

Front Bearing Assembly

Shell

Front

Î

Figure 1

(MSSM0303AE)

Î

Cross Section View of Front and Rear Bearing Assemblies

(Bearing Assembly for 60" and 72" WED Shown. Others similar.)

Î

FIGURE 2

(MSSM0303AE)

Î

Connection From Hydraulic Pump to

Assist in Bearing Removal