MSSMA405AE/8737BV

È

V-BELT TENSION ADJUSTMENTS

FOR 48", 52", 60" AND 72" WASHER-EXTRACTORS

This instruction is to be used for adjusting the belt tension on the following machine models:

48032BHE

48032BTG

48032BTH

48036QHE

48036QTG

48036QTH

52038WE1

52038WTF

52038WTB

52038WTG 52038WTH

60036WE2

60036WE3

60036SG2

60036SG3

60044WE2

60044WE3

60044SG2

60044SG3

72044SG2

72044SG3

72044WE2

72044WE3

72044WTB

72044WTG 72044WTH

A belt tension testing device (Milnor

®

part number 30T001) and a straight edge are required when tensioning

unbanded belts.

Ê

Tension Settings—Unbanded Belts

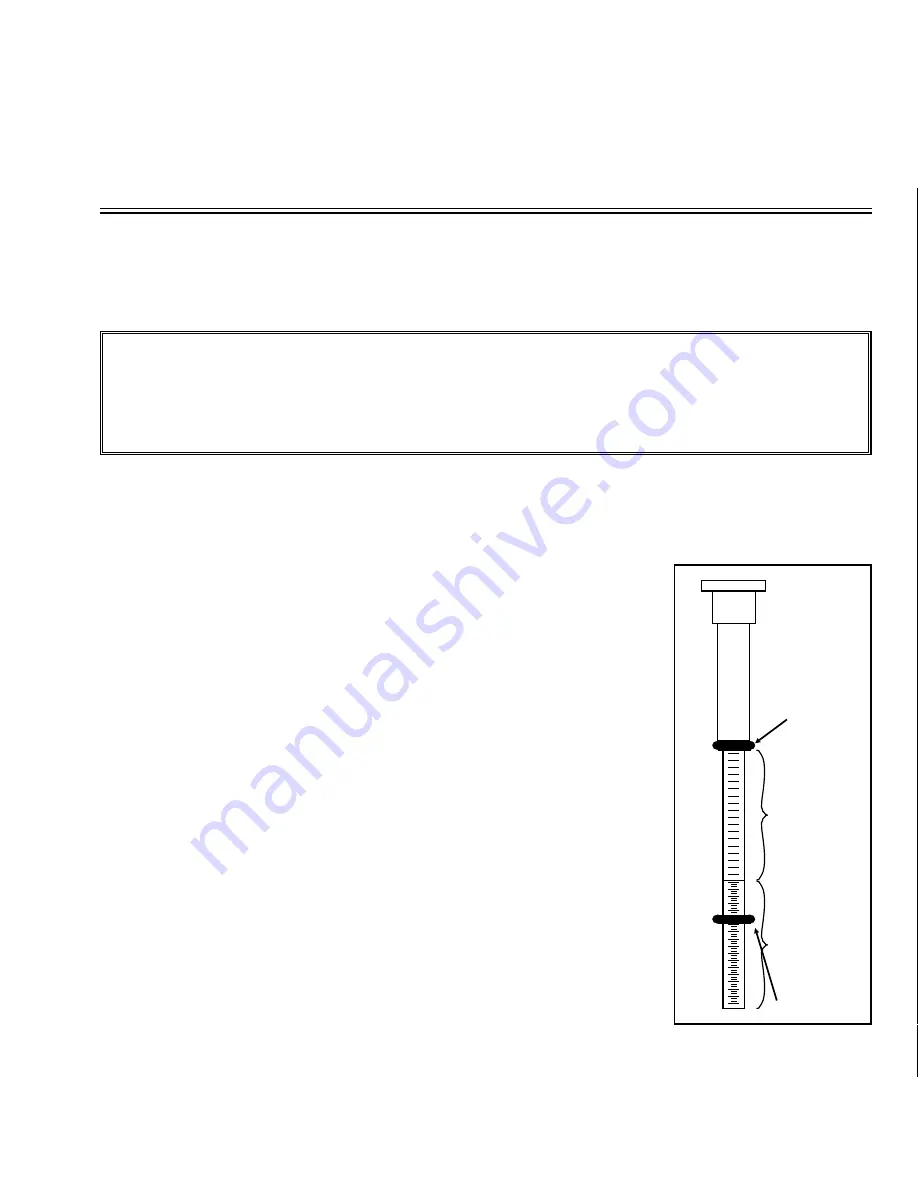

Set the o-rings on the tension testing device (see FIGURE 1) as follows:

1. Move the upper o-ring to the topmost position, resting against the bottom edge

of the cap.

2. Find the proper belt deflection setting (by machine model and belt function) in

the appropriate table below.

3. Move the lower o-ring on the tension tester to this deflection setting on the in-

ches scale.

NOTE 1: The tension testing device is marked on one side in inches and pounds

and on the other side in centimeters and kilograms. All values in the tables are in

inches (in.) and pounds (lbs.).

NOTE 2: The instruction sheet provided with the tension testing device should

not be used. Use only the instructions provided herein.

NOTE 3: The reference (ref.) code shown in the tables are for factory use only.

Ê

Belt Tension Measurements

Ë

Unbanded Belts

1. Place a straight edge along the top edge of the belt to be tested so that it spans both pulleys. Place the tension

tester in the center of the belt and press down on the cap until the lower o-ring is in line with the straight

edge, as shown.

2. Read the setting of the upper o-ring on the lbs scale of the tension tester.

3. Compare this value with the acceptable range in the appropriate table. If the belt is brand new (has never been

run), use the range in the Initial Tension column. If the belt is not brand new, locate the acceptable range in

the Final Tension column.

4. If the reading on the tension tester is less than the range shown in the table, the belt is too loose and must be

tightened. If the reading is greater than the range shown in the table, the belt is too tight and must be

loosened. Adjust the belt until the reading falls within the acceptable range in the table.

Upper o-ring

Deflection

force scale

(read down)

Deflection

distance

scale

(read up)

Lower o-ring

Î

FIGURE 1

(MSSMA405AE)

Î

Tension Settings

Lower o-ring

Straight edge

Î

FIGURE 2

(MSSMA405AE)

Î

Measuring Belt Tension