MSSM0126AE/9243AV

È

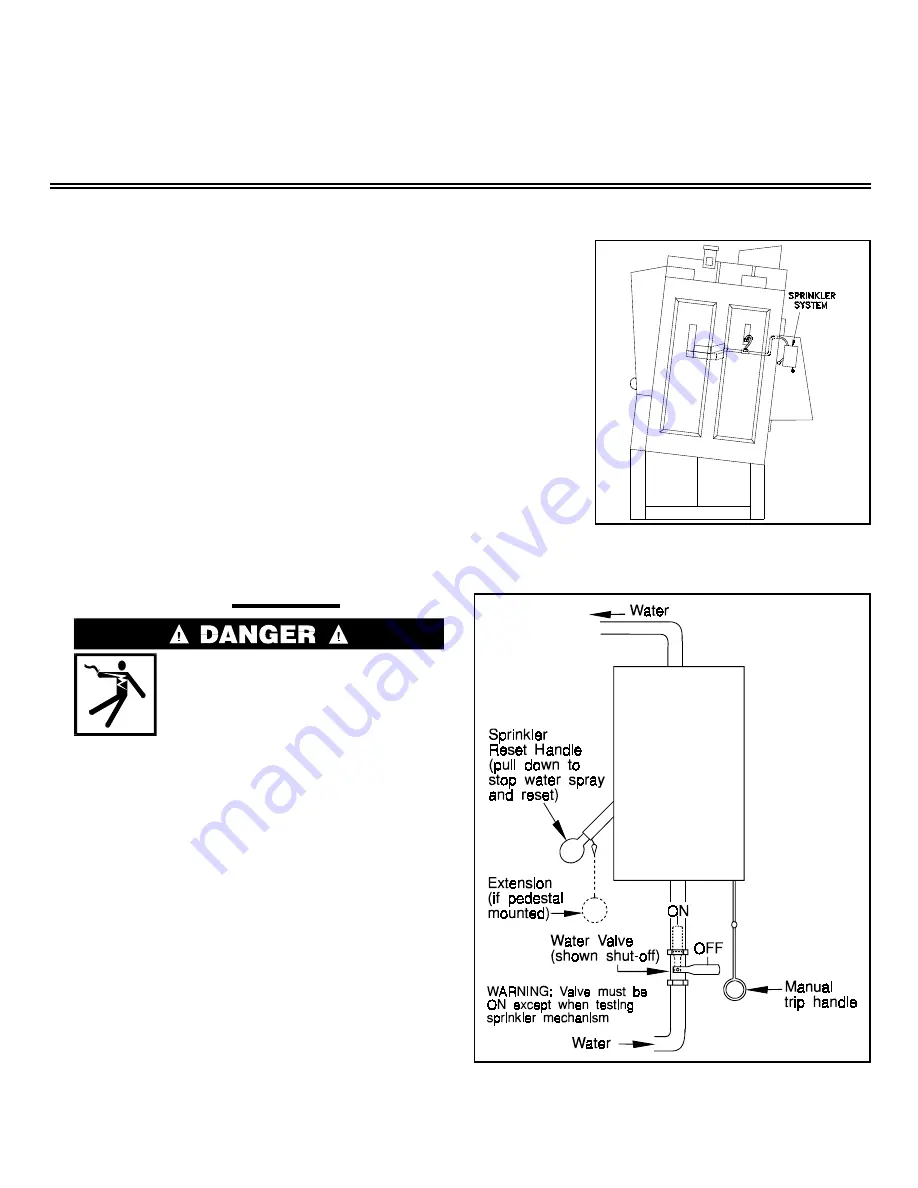

ABOUT THE AUTOMATIC WATER SPRINKLER

Ë

What To Do First, If the Sprinkler Actuates

— I n t h e u n-

likely event of a fire in the basket and ensuing sprinkler actuation, the three

wire relay drops out, the basket stops rotating and the unload door releases.

The sprinkler system (FIGURE 1) must be manually reset and the machine

checked for obvious and hidden damages before being returned to service.

Ë

Stopping the Water Spray and Resetting the Sprinkler

—

Once the fire (if any) is extinguished, pull down the sprinkler reset handle

(FIGURE 2) to stop the water spray and reset the sprinkler. Permit the

water to drain from the basket housing and base.

Ê

Checking for Obvious Damage

S H O C K H A Z A R D — E l e c t r i c a l

power can cause death or severe

injury.

Lock OFF and tag out power to the machine

main bus at the wall disconnect before check-

ing for obvious damage. Power switches on

control panel disable only control circuit

power in certain electrical boxes.

Inspect the interior for damage, especially the basket

surface, support shaft seals, T-seal, and support rollers.

Also check and dry damp electrical connections. If there is

no obvious damage, restore dryer power and remove the

goods as explained in “Removing Goods” in this section.

Ê

Removing Goods

Ë

At the Control Panel

Master switch ON.

Display=

Move the Dryer Load Allowed switch (FIGURE

3) to NO. This tells the shuttle not to deliver a new load

of goods to the dryer. (Although this switch is duplicated

on the function switch panel next to the unload door, it is

possible for the shuttle to send a new load to the dryer

immediately, before an operator could reach the panel).

Ë

At the Function Switch Panel

FIRE AND BURN HAZARDS—

Smoldering goods will fall out

when unload door is opened.

Stand clear with hoses while

unloading.

1. Move the Manual/Automatic switch to MAN-

UAL to fully open the unload door and enable

the Jog switch.

2. Hold the Jog switch CW or CCW as needed to re-

move goods, then return the Manual/Auto-

matic switch to AUTOMATIC.

Ê

Checking for Hidden Damage

With the machine in Manual, check for hidden damage by operating all controls (e.g. Modulating Gas valve,

stripper, etc.). See “ACTUATING OUTPUTS, VIEWING INPUTS AND ACCESSING DATA ACCUMULA-

TION ON THE MARK II DRYER CONTROL” in the Programming, Operating and Troubleshooting manual. To

help determine why a fire occurred, see “HOW TO ACCESS DRY CYCLE DETAILS” in the same section. If the

machine has no mechanical damage and all controls work normally, return machine to normal operation.

Î

FIGURE 1

(MSSM0126AE)

Î

Location of Sprinkler Enclo-

sure

Î

FIGURE 2

(MSSM0126AE)

Î

Sprinkler Controls

WAITING FOR LOAD

******************

Î

FIGURE 3

(MSSM0126AE)

Î

Control Panel

Î

FIGURE 4

(MSSM0126AE)

Î

Function Switch Panel