Torque Requirements for Fasteners

PELLERIN MILNOR CORPORATION

BIUUUM04 (Published) Book specs- Dates: 20180109 / 20180109 / 20180109 Lang: ENG01 Applic: UUU

Torque Requirements for Fasteners

This document uses Simplified Technical English. Learn more at http://www.asd-ste100.org.

The document about the assembly gives the torque requirements for other fasteners.

If fastener

torque specifications or threadlocker requirements in an assembly document are different

from this document, use the assembly document.

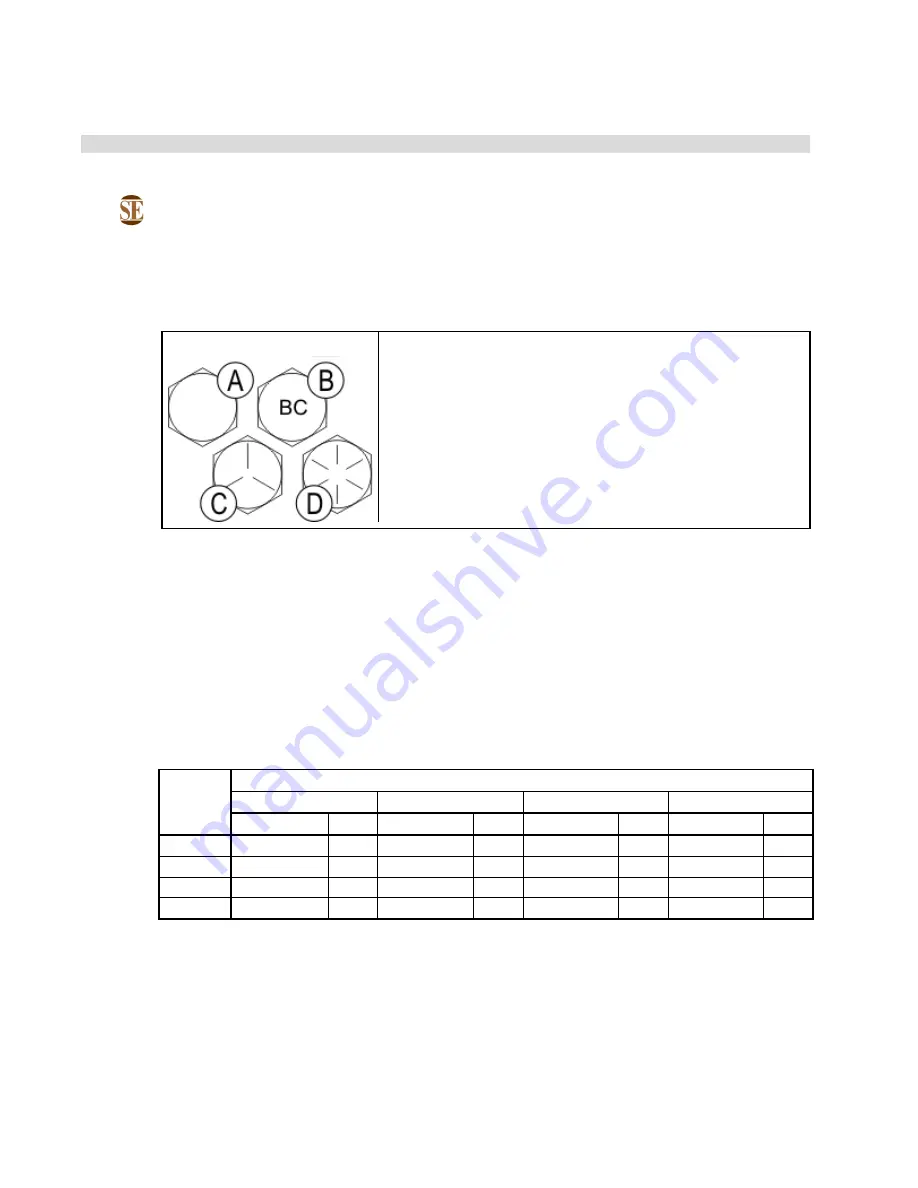

Figure 1: The Bolts in Milnor

®

Equipment

The Marks on Bolt Heads

Legend

A.

SAE Grades 1 and 2, ASTM A307, and stainless steel

B.

Grade BC, ASTM A354

C.

SAE Grade 5, ASTM A449

D.

SAE Grade 8 and ASTM A354 BD

.

1.

Torque Values

These tables give the standard dimension, grade, threadlocker, and torque requirements for

fasteners frequently used on Milnor

®

equipment.

Note 1:

Data from the Pellerin Milnor

®

Corporation “Bolt Torque Specification”

(bolt_torque_milnor.xls/2002096).

1.1.

Fasteners Made of Carbon Steel

1.1.1.

Without a Threadlocker

Table 1: Torque Values for Standard Fasteners with Maximum 5/16-inch Diameters and No Lubricant

Dimension

The Grade of the Bolt

Grade 2

Grade 5

Grade 8

Grade BC

Pound-Inches

N-m

Pound-Inches

N-m

Pound-Inches

N-m

Pound-Inches

N-m

1/4 x 20

66

7

101

11

143

16

126

14

1/4 x 28

76

9

116

13

163

18

--

--

5/16 x 18

136

15

209

24

295

33

258

29

5/16 x 24

150

17

232

26

325

37

--

--

49

Summary of Contents for MilTouch MWF27Z8 Series

Page 2: ......

Page 23: ...Installation 1 19 ...

Page 39: ...Service and Maintenence 2 35 ...

Page 61: ...Drive Assemblies 3 57 ...

Page 72: ......

Page 73: ...Suspension 4 69 ...

Page 78: ......

Page 79: ...Shell and Door Assemblies 5 75 ...

Page 89: ...Water and Steam Piping and Assemblies 6 85 ...

Page 96: ......

Page 97: ...Chemical Supply Devices 7 93 ...

Page 107: ...Dimensional Drawings 8 103 ...

Page 108: ......

Page 109: ...105 ...

Page 110: ...106 ...