Torque Requirements for Fasteners

PELLERIN MILNOR CORPORATION

Apply the threadlocker only to the areas where the fastener threads and the mating threads

engage.

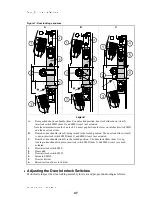

Figure 2: Blind Hole

Application

Coverage

Legend

A.

No threadlocker here

B.

Apply here

C.

Fill all space with threadlocker

.

3.1.

Blind Holes

1. Apply the threadlocker down the threads to the bottom of the hole.

2. Apply the threadlocker to the bolt.

3. Tighten the bolt to the value shown in the correct table (

to

3.2.

Through Holes

1. Put the bolt through the assembly.

2. Apply the threadlocker only to the bolt thread area that will engage the nut.

3. Tighten the bolt to the value shown in the correct table (

to

Figure 3: Through Hole

Application

Legend

A.

No threadlocker here

B.

Apply the threadlocker to this area

x.

Nut depth

.

3.3.

Disassembly

—For high-strength threadlocker, apply heat for five minutes. Disassemble with

hand tools while the parts are hot.

For low-strength and moderate-strength threadlocker, disassemble with hand tools.

55

Summary of Contents for MilTouch MWF27Z8 Series

Page 2: ......

Page 23: ...Installation 1 19 ...

Page 39: ...Service and Maintenence 2 35 ...

Page 61: ...Drive Assemblies 3 57 ...

Page 72: ......

Page 73: ...Suspension 4 69 ...

Page 78: ......

Page 79: ...Shell and Door Assemblies 5 75 ...

Page 89: ...Water and Steam Piping and Assemblies 6 85 ...

Page 96: ......

Page 97: ...Chemical Supply Devices 7 93 ...

Page 107: ...Dimensional Drawings 8 103 ...

Page 108: ......

Page 109: ...105 ...

Page 110: ...106 ...