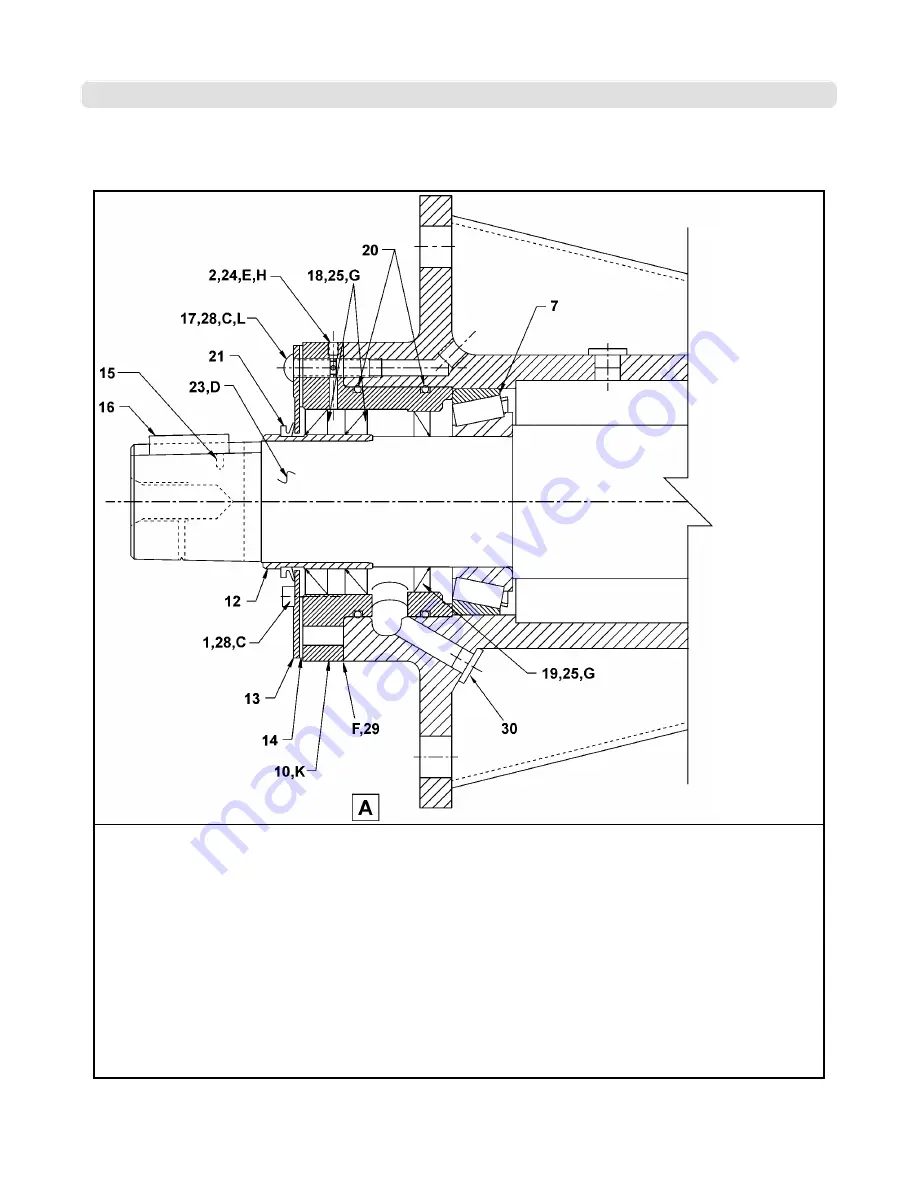

Figure 2.

Bearing Housing Front

Legend

A.

Detail view of the bearing housing front.

C.

Apply anti-seize compound to the bolt.

D.

Clean the shaft and the inner sleeve. Make sure that they are clean and free from oil. Apply adhesive, then the

sleeve. Make sure of a bond on a minimum of 75% of the surface.

E.

Apply adhesive to the bolt.

F.

Add shims to a thickness of .004 inches — .005 inches. The shaft must turn in the housing. For details of the rec-

ommended procedure, refer to the document MSSM0261AE.

G.

Apply adhesive to the outer circumference of the seals. Let the adhesive dry 24 hours. Make sure that all surfaces

are clean and free from oil before you assemble.

H.

Set the set screw to be flush with the outer edge of the seal holder.

K.

The seal holders must be fully down before you tighten the fasteners.

L.

When you change the seal holder, torque item 17 to 150 IN. LBS. This bolt has a nylon insert and a hole to let

grease to the water seals. Torque all remaining bolts to the standard torque.

Bearing Housing Components MWF27

2 of 4

BPWMAB03 / 2017502A

BPWMAB03

0000166675

B.2

12/11/17 3:34 PM

Released

61

Summary of Contents for MilTouch MWF27Z8 Series

Page 2: ......

Page 23: ...Installation 1 19 ...

Page 39: ...Service and Maintenence 2 35 ...

Page 61: ...Drive Assemblies 3 57 ...

Page 72: ......

Page 73: ...Suspension 4 69 ...

Page 78: ......

Page 79: ...Shell and Door Assemblies 5 75 ...

Page 89: ...Water and Steam Piping and Assemblies 6 85 ...

Page 96: ......

Page 97: ...Chemical Supply Devices 7 93 ...

Page 107: ...Dimensional Drawings 8 103 ...

Page 108: ......

Page 109: ...105 ...

Page 110: ...106 ...