Sterylis VS Manual

| 14

4.3 Operating principle

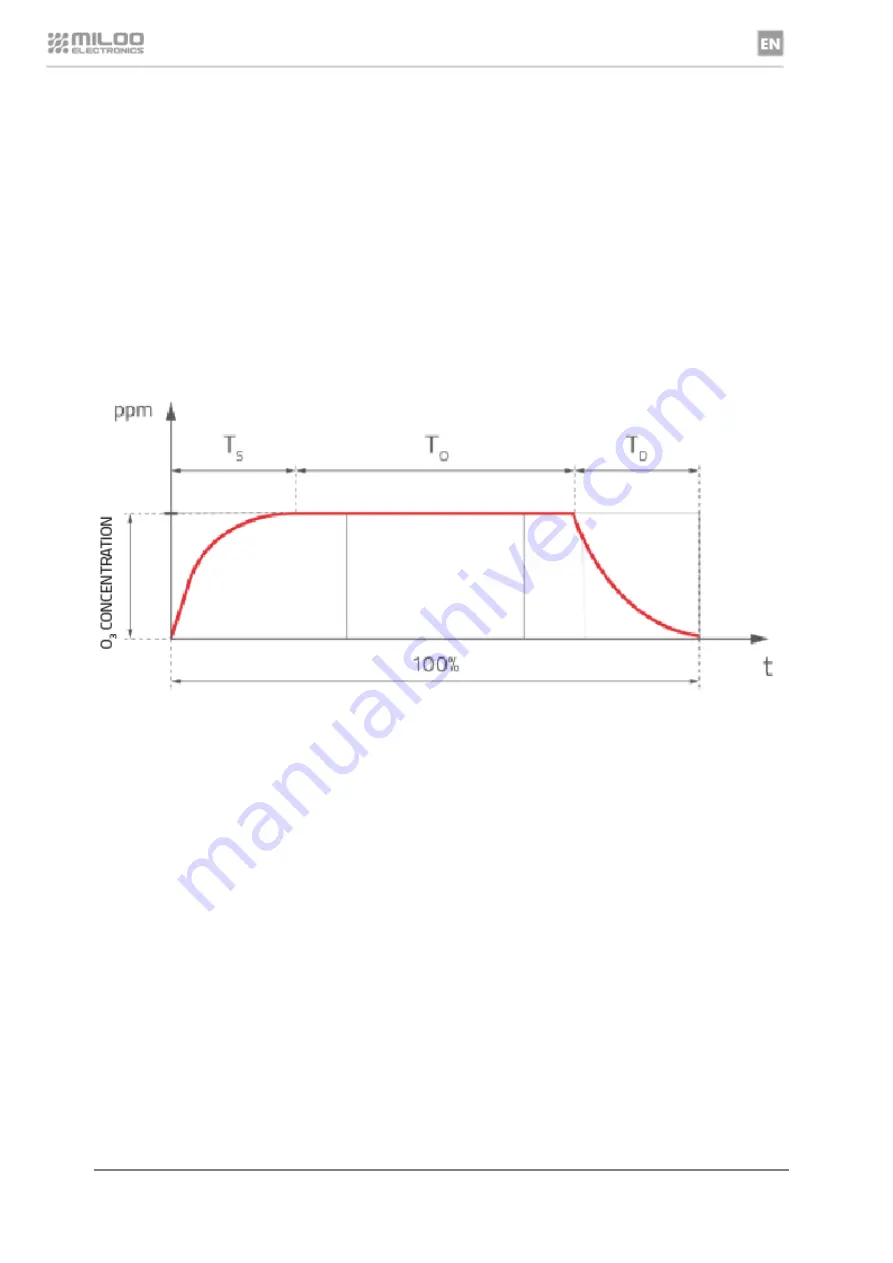

Ozoning: The steriliser has ozone generators, the number of which varies depending on the version. The ozoning process

consists in starting all the ozone generators in the device and achieving a concentration of O

3

particles in the room of 7

ppm. Once the required concentration is reached, the generators are disconnected until the concentration drops to 6 ppm.

At this point, the ozone generators are restarted and aim to reach a concentration of 7 ppm again. Then they are

disconnected again and the process repeats itself. This is the so-called modulated efficiency of the ozone generators by

pulsation. Changes in the concentration of ozone in the room are shown in the diagram below. In the manual ozone

sterilisation mode the user can change the settings for the working ozone concentration and ozone duration.

Time T

S

is the time required to achieve the sterilising ozone concentration (default 5 ppm), T

O

is the time required for the

sterilisation process, controlled by the controller, depending on the achieved ozone concentration, T

D

is the time required

for the process to return to a safe ozone concentration (0.1 ppm), controlled by the controller, assisted by an ozone

destructor.

For very high ozone concentrations, the ozone concentration may be lower and be at least 2 ppm. However, this is

sufficient to allow for an effective ozoning process with an extended duration.

Ozone is a powerful oxidant, so it is perfect for killing bacteria, viruses, moulds and removing unpleasant odours. It is

highly reactive, which means that it reacts with other molecules, breaking down their structures. The effectiveness of

ozone in eliminating odours lies in the fact that, as a gas, it is able to reach wherever there is air, i.e. all the cracks, nooks

and gaps inside a room. It breaks down particles present in the air responsible for odour in rooms and kills bacteria,

viruses or moulds. Ozoning is an effective method of disinfection, deodorisation or disinsectisation, thanks to which

rooms are not only free of unpleasant aromas but also safe and sterile. Ozone is used to sterilise living quarters, public

areas, health care facilities (including operating theatres), processing plants (e.g. butcher's shops), warehouses, fruit and

vegetable storage facilities, catering facilities for refrigeration chambers and shop sales halls. Ozoning is also used to

extend the shelf life of food products, e.g. by eliminating fungi, bacteria and moulds, which allows to significantly extend

the storage period of vegetables, fruit or dried tobacco or fruit in storage facilities. It is also a well-known and effective

way of getting rid of unpleasant smell from changing rooms, classrooms or gymnasiums in schools. Ozoning is a very

effective method of odour removal and deodorization of clothes and shoes, often used in costume and costume rentals or

wardrobes in theatres. Ozone is also used to sterilise and remove odours from children's toys, especially in public

playrooms for children.

UV-C disinfection: The UV-C lamps used in the device emit radiation of a strictly defined wavelength of 253.7 nm. It is a

wavelength that has a photolithic effect on microorganisms such as bacteria, moulds, yeasts and viruses. Ultraviolet light

of this wavelength effectively penetrates their cell membrane destroying the structure of their DNA and thus preventing