5

P

R

EP

A

R

IN

G

TH

E

IN

ST

R

U

M

EN

T

27

5

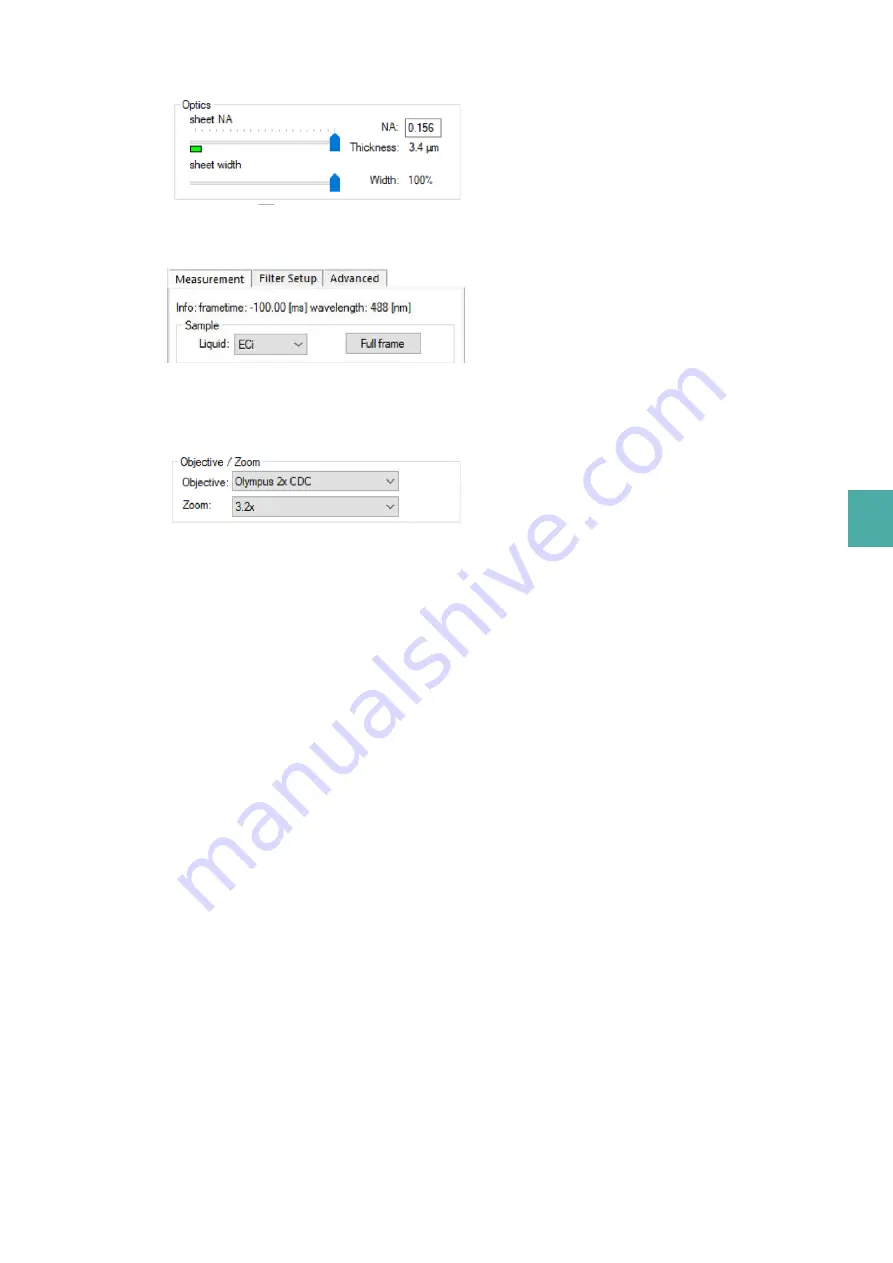

Set

Optics > sheet NA

to the maximum.

6

Set

Optics > sheet width

to 20%.

7

Select the

Measurement

tab, and select the imaging solution used in the cuvette under

Liquid

.

8

Set the exposure time to a value between 100 and 200 ms in the

Camera

view.

9

Select the objective lens, such as Olympus 2× CDC with 3.2× zoom for the Zoom Body. The zoom needs to

be the same as set at the zoom knob.

Summary of Contents for UltraMicroscope II

Page 1: ...UltraMicroscope II Imaging System User manual...

Page 14: ...1 IMPORTANT SAFETY INFORMATION 12...

Page 20: ...2 INTRODUCTION 18...

Page 30: ...5 PREPARING THE INSTRUMENT 28...

Page 38: ...6 LASER ALIGNMENT 36...

Page 46: ...7 SETTING UP AN EXPERIMENT 44...

Page 48: ...8 MAINTENANCE 46...

Page 54: ...10 TECHNICAL SUPPORT 52...

Page 57: ......