에어

구동식가스

부스터컴프레서

8

”

구동부

AG

시리즈

• OM-12J

37

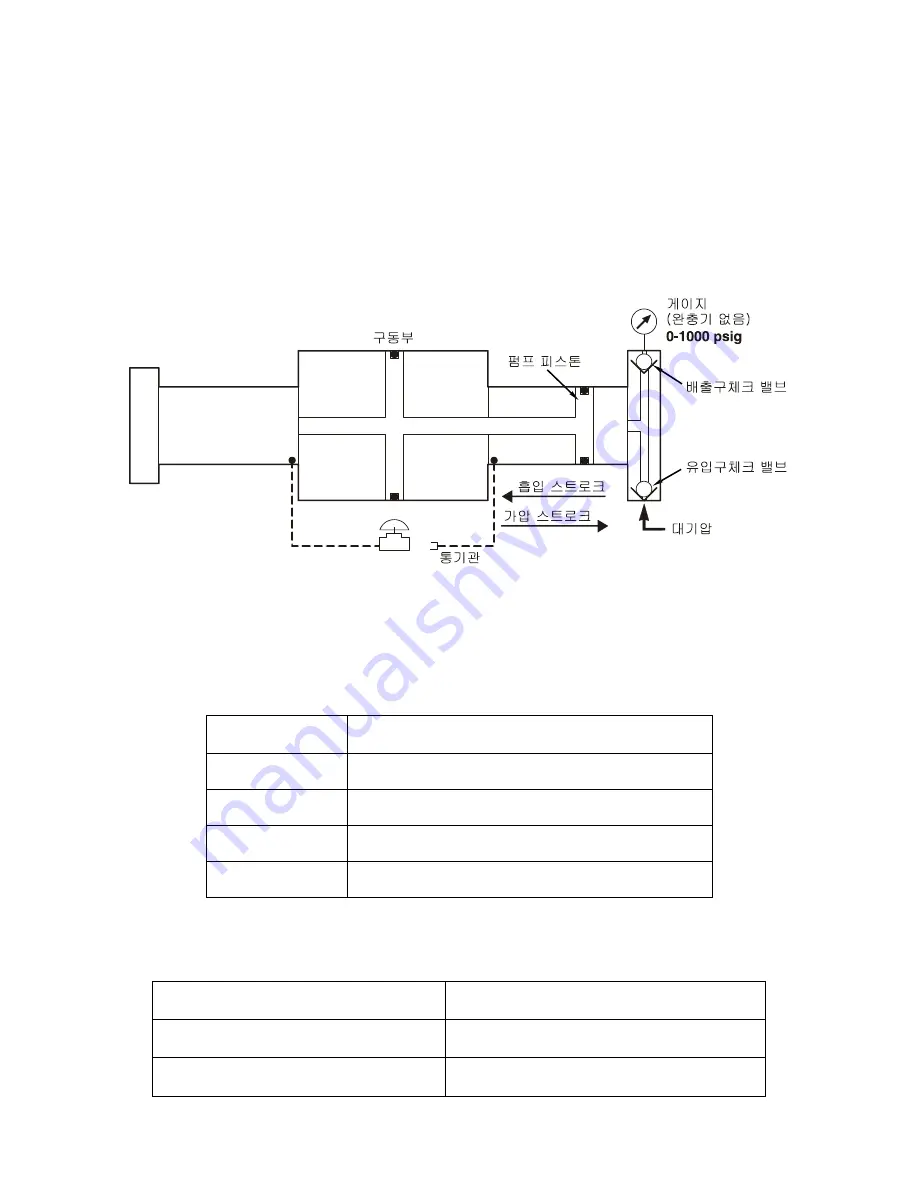

6.2

이론

각

가스

부스터

펌프는

매끈한

가스

배럴

구멍에서

왕복

운동을

하고

흡입

체크를

통해

백

스트로크에서

가스를

흡입하고

이

가스의

대부분을

포워드

스트로크에서

배출

체크를

통해

배출하는

씰이

달린

피스톤으로

구성되어

있습니다

.

따라서

어떤

모델의

어떤

펌프

구성부에도

대기압에서

1000 psig

게이지로

직접

에어를

가압하면

이러한

모든

부품의

상태를

측정할

수

있습니다

.

6.3

구성도

6.4

테스트

:

Install gauge. Cycle drive at moderate speed until pressure stops rising. Record maximum pressure.

6.5

분석

:

6.5.1

다음

압력에

도달하면

가스

구성부가

만족스러운

상태인

것으로

간주할

수

있습니다

.

모델

번호

대기압

유입구에서

최소

압력

, psig

8AGD -5

225

8AGD -14

225

8AGD -30

250

8AGD -60

315

최대

압력이

위에

나타낸

최소

압력보다

낮다면

피스톤

씰

또는

유입구

체크

또는

배출구

체크에서

과도한

누출이

발생하고

있는

것입니다

.

6.5.2

게이지

바늘

움직임

수리

A.

최대값에서

빠르게

떨어짐

A.

배출구

체크

B.

압력

스트로크

중에

천천히

올라감

B.

유입구

체크

또는

피스톤

씰

/

가스

배럴

Summary of Contents for Haskel 8AGD-1

Page 15: ...8 OM 12J 15 2 3 T 2 3 1 4 25 1 8AGT 8AGD 40 1 10 1 2 3 2 3 1 5 1 10 1 80 C...

Page 16: ...8 OM 12J 16 1 8AGD 8AGT 2 8AGT 25mm 145 C...

Page 18: ...8 OM 12J 18 3 5 1 2 2 3 4 4 1 1 bar 5 5 1 CV No 242 CV O...

Page 19: ...8 OM 12J 19 IPA 50 50 5 2 5 2 1 5 2 2 3 O O 4 5 2 3 5 3 4 5...

Page 24: ...8 OM 12J 24 O 5 7 8 5 7 9 6 6 1 6 2 70 bar 6 3...

Page 26: ...8 OM 12J 26 7 7 1 7 2 7 3 1 4 bar 5 2 O O O 9 5 5 5...

Page 29: ...8 AG OM 12J 29 8AGD 8AGT 8AGD 1 2 1 1 8AGD 8AGT 2 2 1 2 2 2 8AGT...

Page 31: ...8 AG OM 12J 31 3 5 1 2 2 3 4 4 1 15 psi 5 5 1 Loctite CV Blue 242 Loctite CV O...

Page 32: ...8 AG OM 12J 32 Stoddard 50 50 5 2 5 2 1 4 5 2 2 3 O O 4 3 4 Pilot shaft end seal...

Page 38: ...8 AG OM 12J 38 B 80 500 psi 7 7 1 7 2 7 3 20 psi 5 2 O O 9 5 5 6 O 6...

Page 41: ...8 AG OM 12J 41 1 8AGD 8AGT 2 2 8AGT 1 300 F...

Page 43: ...8 AG OM 12J 43 4 1 15 PSI 5 5 1 Loctite CV 242 Loctite CV O 50 50 5 2 5 2 1...

Page 44: ...8 AG OM 12J 44 5 2 2 3 O O 4 5 2 3 5 5 2 3 1 O 2 2 1 6 30 5 2 4 5 2 1 5 2 3 3 4 5 6...

Page 48: ...8 AG OM 12J 48 5 7 3 O 5 7 4 O O 5 7 5 O 5 7 6 5 1 5 7 7 O 5 7 8 5 7 9 6 6 1 6 2 1000 PSlG 6 3...

Page 50: ...8 AG OM 12J 50 7 7 1 7 2 7 3 20 psi 5 2 O O 9 5 5 5 O 6...