Air Driven Gas Booster Compressor, 8” Drive AG Series • OM-12J

5

3. Installation

3.1 Mounting

All models will operate in any position required for system operation. However, for Oxygen Gas Boosting

applications, mount all models horizontally with mounting brackets down.

3.2 Environment

All units are protected with plating or materials of construction for installation in normal indoor or outdoor

applications. Special considerations may be advisable on some components if atmosphere is corrosive. If

ambient temperatures will drop below freezing, dryers to prevent condensation of moisture in either the

drive or gas section are advisable.

3.3 Drive System

Incoming air (or gas) piping and components must be large enough to provide sufficient flow for the cycle

rate desired. Minimum size to provide the pumping rates shown in the current catalog is 3/4” I.D. Complex

lines ov

er a considerable distance should be 1” or larger.

The standard drive inlet is a 3/4” female pipe port located in the center of the cycling valve body. As

standard, the pilot air (or gas) to the cycling system is provided through the bent tube assembly from the

1/4” NPT tap below the 3/4” NPT drive inlet port. For external remote pilot, the tube assembly is removed,

the 1/4” NPT tap is plugged, and the pilot air from an alternate source connected to the 1/8” NPT port in

the valve end cap. External pilot pressure should be equal to or exceed drive pressure. The air drive (and

air pilot if external) inlet system should always include a filter since essentially all compressors introduce a

considerable amount of contamination.

The drive requires approximately 25 psi to trigger the valve spool and pilot piston as lubricated at the

factory.

It is not necessary or desirable to use an airline lubricator.

3.3.1 MUFFLERS

For minimum noise level, these may be remotely located. If beyond 6 feet, use 3/4” I.D. pipe, tube or

hose.

3.3.2 PILOT VENT

The pilot system vents a small amount of pilot air (or gas) once per cycle from the 1/8” NPT tap in the flow

fitting end cap. This vent should operate unobstructed. It may also be piped to a remote location if the

pilot gas is hazardous. Vent purge modification with a 15 psi relief is available. Specify modification 56611

for single-ended models and 56611-2 for double-ended models.

3.4 Controls

For general usage the optional standard air controls accessory package includes a filter, an air pressure

regulator with a gauge, and a manual valve for shutoff and speed control. Pumping rates shown in the

current catalog are based on the use of a regulator with a flow capacity equivalent to 3/4” pipe size.

A number of other control options are available to suit specific applications. Among these are: Automatic

start/stop of the drive - sensing gas output and/or gas inlet pressures; high pressure safety relief

protection; cycle counting, cycle rate control, etc.

Consult current catalogs, authorized distributors or the factory.

3.5 Gas System

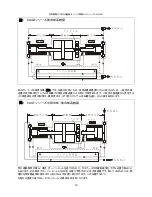

Refer to Figures 1 or 2 and to the detailed installation drawings enclosed covering the specific model. The

installation drawing will provide inlet and outlet port detail and location. When tightening connecting

piping, hold the port fitting securely with a backup wrench. Be certain that the connecting lines and fittings

are of the proper design and safety factor for pressurized gas service.

NOTE: Also see paragraph 2.3 on gas system cleanliness.

Summary of Contents for Haskel 8AGD-1

Page 15: ...8 OM 12J 15 2 3 T 2 3 1 4 25 1 8AGT 8AGD 40 1 10 1 2 3 2 3 1 5 1 10 1 80 C...

Page 16: ...8 OM 12J 16 1 8AGD 8AGT 2 8AGT 25mm 145 C...

Page 18: ...8 OM 12J 18 3 5 1 2 2 3 4 4 1 1 bar 5 5 1 CV No 242 CV O...

Page 19: ...8 OM 12J 19 IPA 50 50 5 2 5 2 1 5 2 2 3 O O 4 5 2 3 5 3 4 5...

Page 24: ...8 OM 12J 24 O 5 7 8 5 7 9 6 6 1 6 2 70 bar 6 3...

Page 26: ...8 OM 12J 26 7 7 1 7 2 7 3 1 4 bar 5 2 O O O 9 5 5 5...

Page 29: ...8 AG OM 12J 29 8AGD 8AGT 8AGD 1 2 1 1 8AGD 8AGT 2 2 1 2 2 2 8AGT...

Page 31: ...8 AG OM 12J 31 3 5 1 2 2 3 4 4 1 15 psi 5 5 1 Loctite CV Blue 242 Loctite CV O...

Page 32: ...8 AG OM 12J 32 Stoddard 50 50 5 2 5 2 1 4 5 2 2 3 O O 4 3 4 Pilot shaft end seal...

Page 38: ...8 AG OM 12J 38 B 80 500 psi 7 7 1 7 2 7 3 20 psi 5 2 O O 9 5 5 6 O 6...

Page 41: ...8 AG OM 12J 41 1 8AGD 8AGT 2 2 8AGT 1 300 F...

Page 43: ...8 AG OM 12J 43 4 1 15 PSI 5 5 1 Loctite CV 242 Loctite CV O 50 50 5 2 5 2 1...

Page 44: ...8 AG OM 12J 44 5 2 2 3 O O 4 5 2 3 5 5 2 3 1 O 2 2 1 6 30 5 2 4 5 2 1 5 2 3 3 4 5 6...

Page 48: ...8 AG OM 12J 48 5 7 3 O 5 7 4 O O 5 7 5 O 5 7 6 5 1 5 7 7 O 5 7 8 5 7 9 6 6 1 6 2 1000 PSlG 6 3...

Page 50: ...8 AG OM 12J 50 7 7 1 7 2 7 3 20 psi 5 2 O O 9 5 5 5 O 6...