4

5

only a few drops of oil at a time. Using too much oil

will cause it to collect in the tool and be noticeable

in the exhaust. Do not use detergent oil, WD-40,

transmission fl uid, motor oil, or other lubricants not

specifi cally designated as air tool lubricant. These

lubricants will cause accelerated wear to the seals,

o-rings and bumpers in the tool, resulting in poor tool

performance and frequent maintenance.

2-3 drops of air

tool lubricant

3/8" NPT quick

connector

Adjusting/Removing Shingle Guide

To adjust the shingle guide, press in the guide button

and slide the guide to the desired location. To remove

the guide, press in the guide button and slide it toward

the nose of the tool and off of the track.

Guide button

Connecting the Air Supply

DANGER

Do not use oxygen, combustible

gases or bottled gases as a power

source for this tool. The tool will explode and

cause death or serious injury.

WARNING

Always use a coupling that dis-

charges all the compressed air in

the tool at the time the fi tting or hose coupling is

disconnected. Using a coupling that does not

discharge the compressed air could cause unin-

tended operation and serious injury.

Use only clean, dry compressed air with a maximum

pressure of 200 psi. Before connecting the tool to the

air supply, check the air compressor regulator gauge

to be sure it is functioning properly, with a range be-

tween 70-120 psi. Air pressure higher than 120 psi

could cause injury and property damage. The correct

pressure is the lowest pressure that will do the job.

To connect the air supply:

1. Remove the plastic plug from the quick connector.

2. Lubricate the quick connector with 2-3 drops air tool

lubricant.

3. Snap the air hose onto the quick connector.

4. Check for air leakage.

NOTE:

Use only a 3/8" NPT quick connector. To improve

the seal between the connector and the tool, and to help

protect against oxidation, apply a PTFE tape or paste

to the connector threads before insertion.

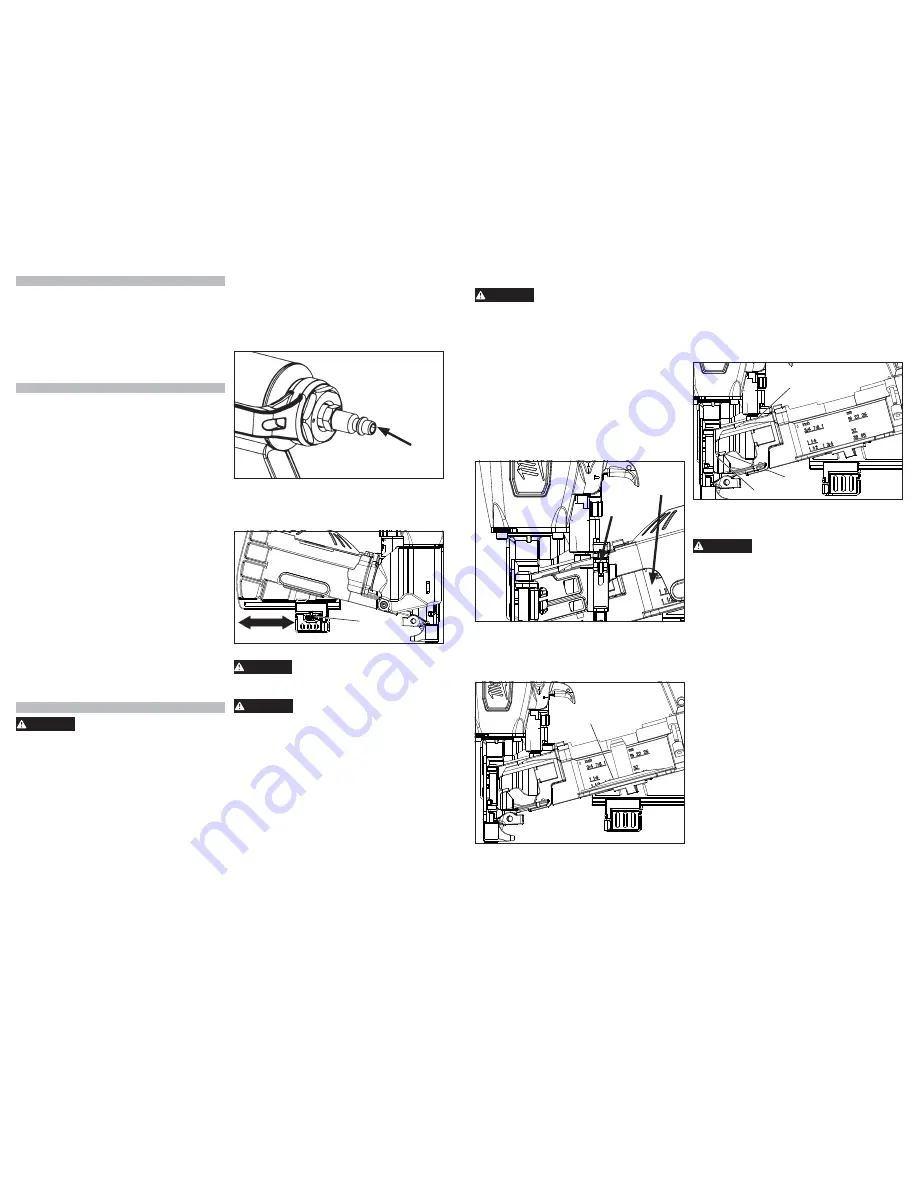

Installing Fastener Coils

WARNING

Always point the tool away from

yourself and others when installing

fasteners. Failure to do so could result in injury.

Always make sure the tool's magazine is EMPTY

before connecting to the air supply. The tool may

actuate when the tool is fi rst connected to the air

supply. Always connect the tool to the air supply

before loading nails to prevent injury from unin-

tended actuation.

Never install fasteners with the workpiece contact

or trigger activated. Failure to do so could result

in injury.

Use only recommended fasteners of the correct

size, length, collation angle and head type, as

indicated on the tool's nameplate. Refer to the

"Accessories" section for information on recom-

mended fasteners. Other fasteners could result in

tool malfunction, leading to injury.

Verify

magazine

is empty

Fastener

door lever

1. Verify that the magazine is empty and then connect

the air supply to the tool.

2. Lay the tool on its side and point the nose of the

tool away from yourself and others.

3. Open the fastener door by pressing the door lever

and lifting up on the door.

Pallet

4. Open the magazine cover.

5. Position the pallet to the correct nail height for the

coil to be used. Read the corresponding nail size

on the back of the magazine. If the size is not cor-

rect, pull up on the pallet and rotate it clockwise for

shorter nails or counterclockwise for longer nails.

Verify that the correct nail size is set.

SPECIFICATIONS

Cat. No. ......................................................7220-20

Operating Pressure .............................. min. 70 PSI

........................................................... max. 120 PSI

Fastener Length ......................................min. 0.75"

.................................................................max.1.75"

Collation Angle................................................... 15°

Fastener Size (Diameter) ..............................0.120"

Air Consumption ................0.08 ft

3

/cycle at 100 PSI

Air Inlet ..................................................... 3/8" NPT

Magazine Capacity ................................... 120 nails

TERMINOLOGY

Actuate

To cause movement of the tool component(s) intended

to drive a fastener.

Actuation System

The use of a trigger, workpiece contact and/or other

operating control, separately or in some combination

or sequence, to actuate the tool.

• Single sequential actuation

An actuation system that requires the workpiece

contact and then the trigger to be activated in a

specifi c sequence to drive a fastener. Additional

actuation can occur when the trigger is released

and reactivated.

• Contact actuation

An actuation system that requires the workpiece

contact and the trigger to be activated in any

sequence to drive a fastener. Additional actuation

can occur when either the workpiece contact or the

trigger is released and reactivated.

• Selective actuation

An actuation system that allows selection of actua-

tion systems: single sequential actuation or contact

actuation.

Fastener

A staple, pin, brad, nail, or other fastening device which

is designed and manufactured for use in the tools.

Jam

An obstruction in the feed or drive areas of the tool.

Workpiece Contact

An operating control element on the tool intended to

be activated by the workpiece to be fastened.

ASSEMBLY

WARNING

Disconnect the air supply from the

tool and remove fastener strips

before changing or removing accessories. Only

use accessories specifi cally recommended for

this tool by the manufacturer. Others may be

hazardous.

The operator and other people in the work area

must wear eye protection in accordance with ANSI

Z87.1. Eye protection does not fi t all operators

in the same way. Make sure the eye protection

chosen has side shields or provides protection

from fl ying debris both from the front and sides.

Exhaust

The exhaust cap can be adjusted to direct the exhaust

as desired. Turn the exhaust cap to the desired lock-

ing position.

Lubricating the Tool

Lubricate the tool with air tool lubricant before con-

necting the air supply. Under low use, lubricate once

a day. Under heavy use, lubricate twice a day. Use

6. Place the center of the nail coil over the pallet post.

The points of the nails must rest on the pallet.

NOTE:

Use only recommended fasteners of the

correct size, length, collation angle and head type

as indicated on the tool's nameplate.

7. Pull the loose end of the coil toward the nose of the

tool. Feed the heads of the nails fl at into the nail

slot. Push the fi rst nail past the feed mechanism

into the nose of the tool.

Nail slot

Feed

mechanism

Nose

8. Close the magazine cover.

9. Close and latch the fastener door.

Removing Fastener Coils

WARNING

To avoid serious injury, disconnect

the tool from the air supply before

removing fastener coils or clearing a jammed

fastener.

Keep fi ngers clear of fastener track of magazine.

Pusher could pinch fi ngers, causing injury.

1. Lay the tool on its side and point the nose of the

tool away from yourself and others.

2. Disconnect the air supply from the tool.

3. Open the fastener door by pressing the door lever

and lifting up on the door.

4. Open the magazine cover.

5. To remove a coil of fasteners, slide the coil off of

the pallet post and out of the nail slot.

6. Reload according to "Installing Fastener Coils".

Clearing a Jammed Fastener

Most jams are caused by a fastener or part of a fas-

tener wedging between the driver blade and the nail

guide. Fastener strips with an incorrect collation angle

or the wrong fastener type (such as round head fasten-

ers) may cause continuous jamming. To clear the jam:

1. Lay the tool on its side and point the nose of the

tool away from yourself and others.

2. Disconnect the air supply from the tool and remove

fastener coil.

3. With the fastener door and magazine still open,

check for and remove any loose nails or debris.

4. If a nail is jammed in the nail guide, insert a screw-

driver into the end of the nail guide. The tip of the

screwdriver should contact the tip of the driver blade.

5. Tap the screwdriver gently with a hammer. The

screwdriver will push the driver blade back, freeing

the jam.

6. Remove the fastener and other debris (use needle-

nose pliers if necessary).

7. Follow the steps under "Required Daily Testing"

before restarting the work.