5

ACCURACY FIELD CHECK

NOTICE

Perform the Accuracy Field Check

procedure immediately upon unboxing

of each new Laser Level and before exposure to

jobsite conditions. See "Accuracy Field Check"

for information.

Should any deviation from listed

product accuracy be found, please con-

tact a MILWAUKEE service facility. Failure to do so

could result in rejection of warranty claim.

Influences on Accuracy

Ambient temperature gradients can impact laser

accuracy. For accurate and repeatable results, the

following procedure should be conducted with the

laser elevated off the ground and placed in the center

of the working area.

Abusive treatment of the Laser Level, such as exces-

sive impacts from drop, can also lead to deviations

in product accuracy.

Therefore, it is recommended to conduct the Field

Check procedure after any impact or before complet-

ing any critical jobs.

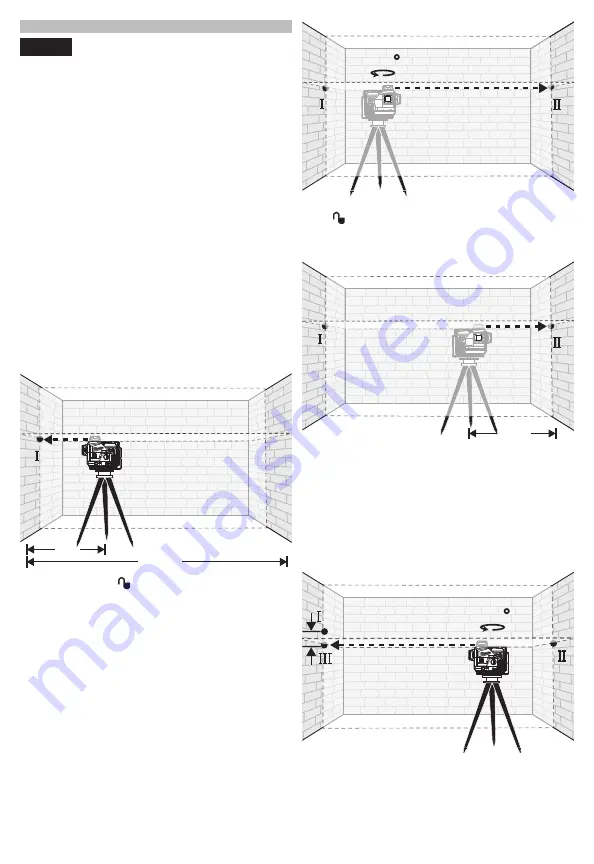

Horizontal Height Accuracy

A free measuring distance of approximately 66' on a

firm surface between two walls or structures A and

B is required for this check.

It is also suggested to mount the Laser Level to a

Tripod for easy adjustment.

1. Securely mount the tool within 1' of wall A.

66'

1'

A

B

2. Turn the tool to ON. Turn on Horizontal Plane

and Side Vertical Plane.

3. Direct the front laser beams against the nearest

wall A and allow to self-level. Mark the center of

where the horizontal and vertical lines cross on

the wall (point I).

4.

Rotate the tool 180° without changing the height,

allow it to self-level, and mark the center of where

the horizontal and vertical lines cross on the op-

posite wall B (point II).

A

B

180

5. Move the tool within 1' of wall B. Turn the tool

to ON. Turn on Horizontal Plane and Side

Vertical Plane. Align intersection of the horizontal

and vertical lines in the general direction of point

II on wall B.

A

B

1'

6. Adjust the height of the tool (using the tripod or by

adding shims, if required) such that the intersection

of the vertical and horizontal lines are projected

exactly against the previously marked point II on

wall B. Allow the tool to self-level.

7.

Rotate the tool 180° without changing the height,

allow it to self-level, and mark the intersection of

the laser lines on wall A (point III). Point III should

be aligned as vertically above or below point I on

wall A as possible.

BB

180

A

d

8.

The distance between points I and III on wall A is

the height deviation (d) of the tool. This distance

should not exceed 1/8" (max.) at 33' (1/2" at 132').

For the Measuring distance of 2 x 66' = 132', the

maximum allowable deviation (d) is: 132' x ±1/8"

÷ 33' = ±1/2".