Not for

Reproduction

25

Installation

Collector Installation

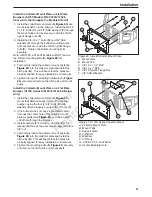

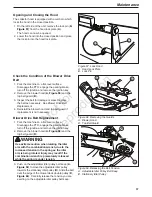

Remove the Rear Engine Shield (If equiped)

1. If the engine is hot, allow sufficient time for the

muffler to cool to prevent a burn injury during

installation.

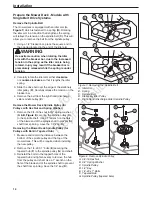

2. Remove the rear engine shield (

C,

Figure 34

) from

the top of the rear bumper (

D

) by removing the 3/8”

hardware (

A, B, & E

) securing the shield to the

bumper.

C

D

E

A

B

Figure 34. Remove the Rear Engine Shield

A. 3/8-16X1” Bolts

B. 3/8” Washers

C. Rear Engine Shield

D. Rear Bumper

E. 3/8” Nylon Flange Nuts

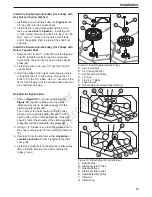

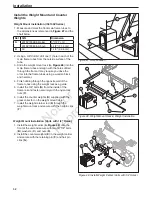

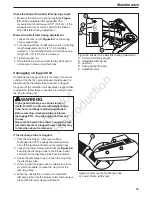

Position the Collector Mount Plate on Models with

the Three (3) Round Tube Bumper Design

1.

ISX2200 Models Only:

Install the collector mount

plate (

A,

Figure 35

) and mount tabs (

B

) onto the

bumper. Install two (2) U-bolts (

C

) over the middle

tube, through the mount tabs and loosely secure

with four (4) 3/8-16 nylock flange nuts (

D

).

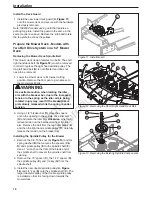

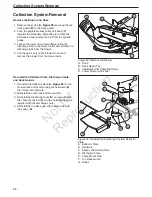

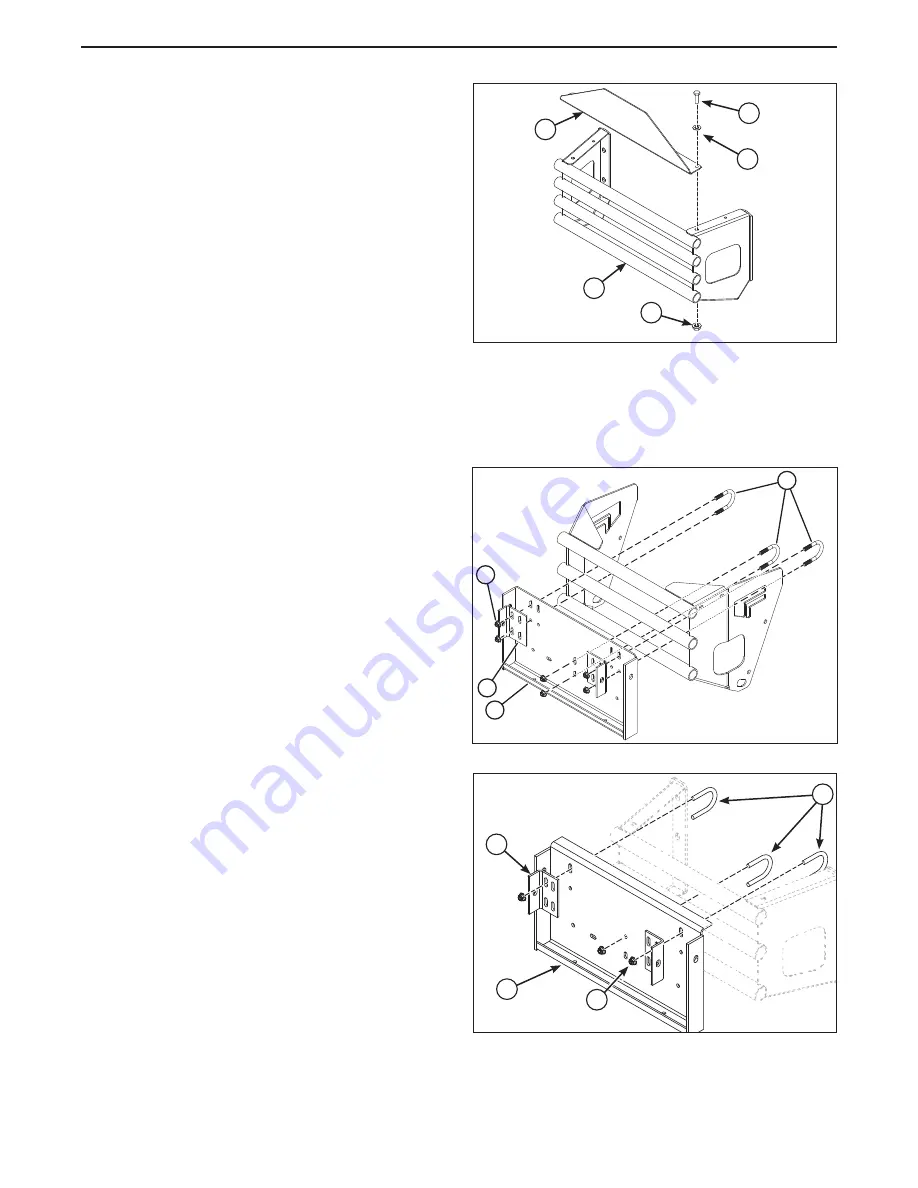

All Other Models:

Install the collector mount

plate (

A,

Figure 36

) and mount tabs (

B

) on to

the bumper. Install two (2) U-bolts (

C

) over the

top bumper tube and through the mount tabs and

loosely secure with four (4) 3/8-16 nylock flange

nuts (

D

).

NOTE: On IS500Z models use the inner mounting

holes when installing the collector mount plate and

mount tabs to the bumper with the 3/8-16 U-bolts

2.

ISX2200 Models Only:

Install the remaining U-bolt

(

C,

Figure 35

) over the bottom bumper tube and

loosely secure with a 3/8-16 nylock flange nut (

D

).

All Other Models:

Install the remaining U-bolt

(

C,

Figure 36

) over the middle bumper tube and

loosely secure with a 3/8-16 nylock flange nut (

D

).

3. Center mount plate on the bumper and tighten the

center U-bolt.

B

A

D

C

Figure 35. Install Collector Mount Plate - ISX2200

Figure 36. Install Collector Mount Plate - All Other

Three Tube Models

A

C

D

B