2-18

Checking the Tool Status

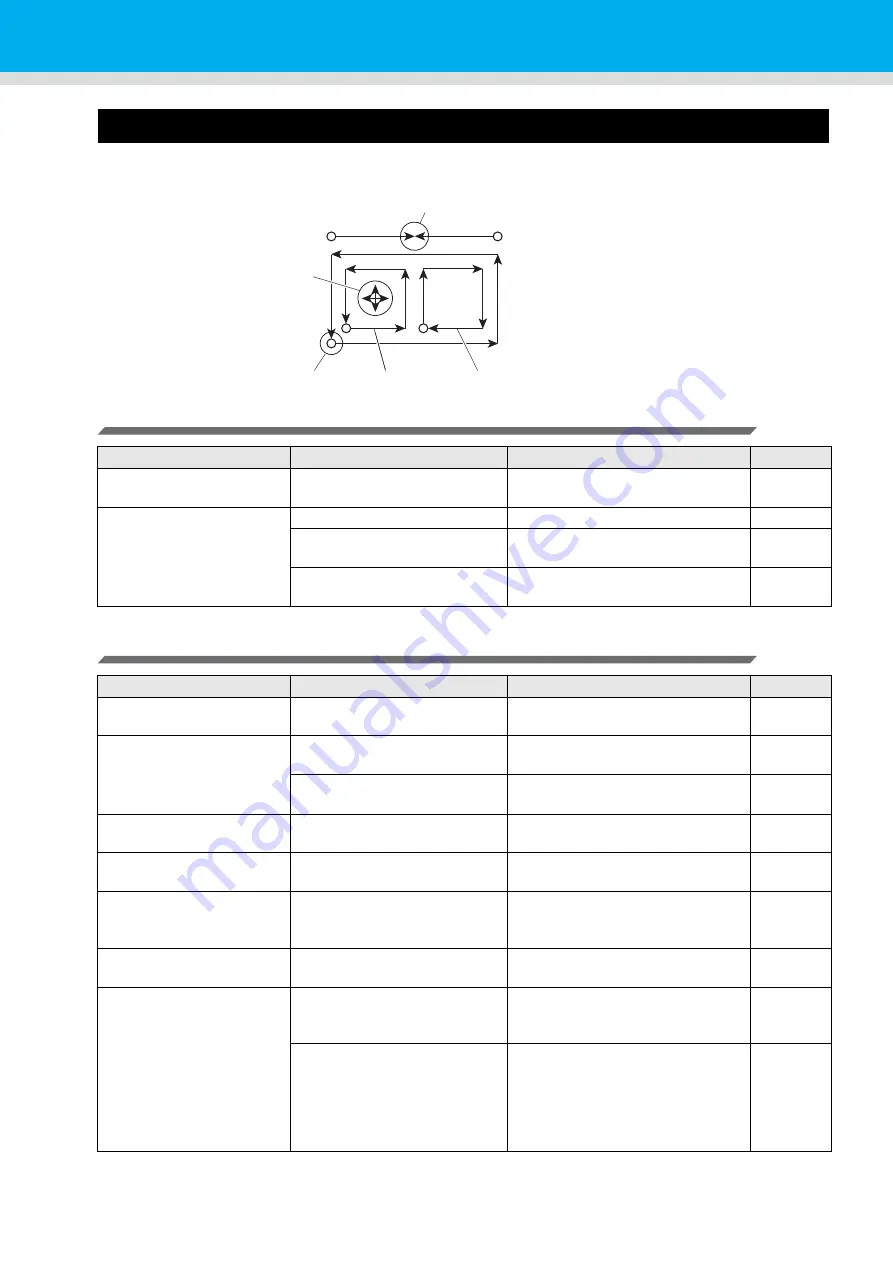

Make a test cut using the tool selected by the Tool Select function. This section describes the check items for

each tool.

Pen

Reciprocating Cutter /

Cutter

Check Point

Cause

Remedy

See page

Point A contact points do

not match

Pen incorrectly mounted.

Fully tighten the holder screw.

Lines broken or faint

Out of ink

Replace the pen with a new one.

Press value low

Increase the “PRESSURE” in the

cutting conditions.

Speed is too high, causing the

pen to lift.

Decrease the “SPEED” in the

cutting conditions.

Check Point

Cause

Remedy

See page

Point B is not in the cross

Blade of the cutter is eccentric.

Please perform the pattern B of

"Adjusting Eccentricity".

Point A contact points do

not match

“END CORR.” value too low in

cutting conditions.

Increase the “END CORR.”.

Blade is mounted eccentrically

Conduct Adjust Eccentricity in tool

adjustments.

Lines displaced at Point A

Abnormal angle

of tial cutter

Conduct

Adjust

in

tool

adjustments.

Cutting incomplete

Press value low

Increase the “PRESSURE” in the

cutting conditions.

Cutting

incomplete

at

corners

The “START CORR.” and “END

CORR.” values in the cutting

conditions are too low.

Increase the “START CORR.” and

“END CORR.”.

D and D' have different

dimensions

Blade is mounted eccentrically

Conduct Adjust Eccentricity in tool

adjustments.

Too many cuts at Point C

“F OFFSET” or “END CORR.”

value is too large.

Decrease the “END CORR.” or

“END CORR.” in the cutting

conditions.

Blade is mounted eccentrically

Please do the pattern A of “Adjust

Eccentricity” of tool adjustment.

Even the adjustment value is the

same, the cut amount is different by

the cutter blade to be used. Please

adjust to suit the purpose.

Point A

Point B

Point C

Point D

Point D'

Summary of Contents for CFL-605RT

Page 7: ...vi ...

Page 14: ...xiii ...

Page 48: ...2 8 1 Put the workpiece on the cutting panel 2 Press ...

Page 68: ...2 28 ...

Page 138: ...4 22 ...

Page 168: ...6 24 ...

Page 169: ...D202786 14 30062016 ...