CHAPTER 3

APPLIED FUNCTIONS

3-27

Command

Setting Value

Description

ROLL IP INIT LG

FULL, Yx 1.4, 1.0 - 3.0-5.0m (1 per step)

According to CAD SPEC

NR TO !PG

YES, NO

According to CAD SPEC

ROLL BE MARG

0 - 25 - 125mm (1 per step)

Cutting position of autocut is

set.

SKEW CHECK

OFF, 5 - 15mm (5 per step)

Slippage of roll is detected.

IN CMD ---> PEN INIT

YES, NO

When the tool setting mode

i s “ M A N U A L , ” s e l e c t

“NO.” If “YES” is selected,

tool parameters (speed, pres-

sure, etc.) will be initialize

when MGL-II command

“IN” is received.

VIBRATION

0 - 5 times

Number of times to try cut

again when autocut is not

executed is assigned.

JOG-SPD

0 - 85cm/s

Speed at JOG key move is

assigned.

SL-CUT

0, 2, 5, 10

Slant cutting amount setting

for auto-cut.

shift-JIS

ENABLE, DISABLE

Shift JIS setting

The underlined values are factory-designated settings at the time of delivery.

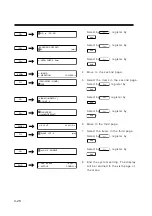

SYSTEM SETTING

The following settings are available in the system setting.

1

Display the sixth page of the menu.

2

Select [CONFIG].

3

Set the items in the first page.

Select by

-F3+

, register by

END

.

-F4+

<--ROLL -IP COM-CONV-->

<--ROLL-R-OFF SKEW-->

-F1+

[ROLL IP LENGTH]

Y x 1.4

-PAGE+

<--GDP : 0.025 I / F SET-->

<--AUTO-I/F CONFIG-->

Summary of Contents for cg-100AP

Page 16: ...xiv ...

Page 70: ...1 54 ...

Page 108: ...2 38 ...

Page 145: ...CHAPTER 4 SELF DIAGNOSIS FUNCTION 4 9 DEMONSTRATION PATTERN 1 2 Demonstration Pattern 1 ...

Page 146: ...4 10 Demonstration Pattern 2 ...

Page 173: ...CHAPTER 6 APPENDIX 6 13 Table of 82 special character codes supported ...

Page 179: ...D200310MAC 2 00 09061999 ...

Page 180: ... MIMAKI ENGINEERING CO LTD 1999 6 Printed in japan ...