5-2

No

No

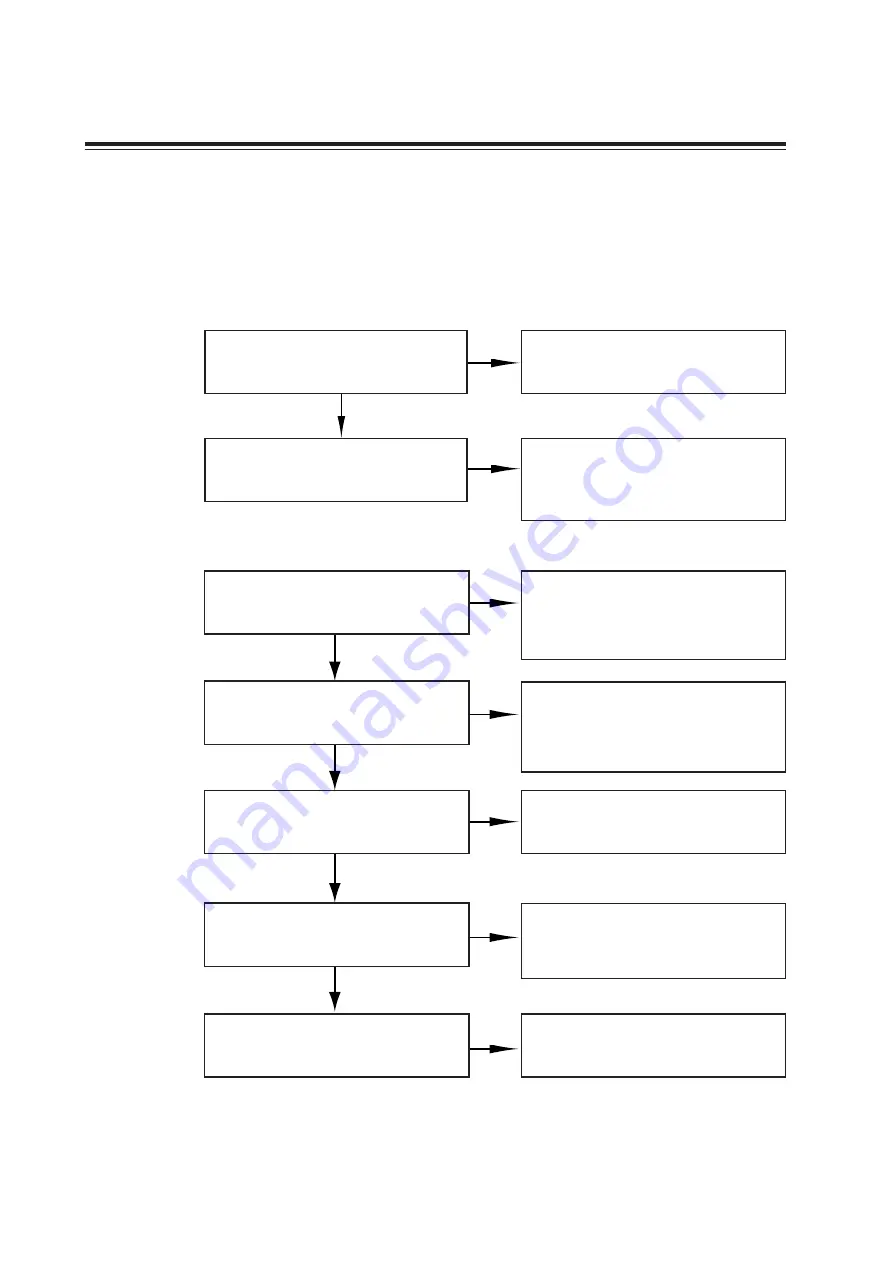

INDICATIONS OF FAILURE

Methods to solve troubles not displayed on the display panel shall be explained herein. Before concluding a

failure, confirm in accordance with the following flow chart. If the situation does not change by the confirmation,

contact with the nearest MIMAKI Distributor upon entering necessary informations in the "INQUIRY SHEET"

(P.6-18)

The power can not be applied.

The paper cannot be fed normally at the time of paper loading.

Is the power cable properly con-

nected?

Properly connect. (See page 1-22.)

Is the power output receptacle

compatible with the power SPEC?

Connect to the receptacle agreed

with the power SPEC. (See page

1-22.)

Yes

No

Is the paper properly secured with

the right and left pinch rollers?

Secure the paper at the correct

position.

For roll paper: See page 2-25.

For leaf paper: See page 2-29.

Are the pinch rollers properly

placed on the grid roller?

Move the pinch rollers until they are

properly placed on the grid roller.

For roll paper: See page 2-25.

For leaf paper: See page 2-29.

Is the paper set straight without

lean?

Correct the lean of paper.

:

See page 2-25

Is an extremely thin paper placed on

the machine?

Set the paper type to “LEAF-THIN”

and lower the speed.

See page 3-22

Has the paper sensor been wiped

clean?

Wipe clean the paper sensor.

See page xiii

Yes

Yes

Yes

Yes

No

No

No

No

Summary of Contents for cg-100AP

Page 16: ...xiv ...

Page 70: ...1 54 ...

Page 108: ...2 38 ...

Page 145: ...CHAPTER 4 SELF DIAGNOSIS FUNCTION 4 9 DEMONSTRATION PATTERN 1 2 Demonstration Pattern 1 ...

Page 146: ...4 10 Demonstration Pattern 2 ...

Page 173: ...CHAPTER 6 APPENDIX 6 13 Table of 82 special character codes supported ...

Page 179: ...D200310MAC 2 00 09061999 ...

Page 180: ... MIMAKI ENGINEERING CO LTD 1999 6 Printed in japan ...