Chapter 8 Dealing with Problems

160

8.1 Troubleshooting

For information on troubleshooting, refer to this chapter. Refer to the following URL for frequently asked

questions (FAQs) about this product and customer support videos.

If the recommended corrective action does not resolve the problem, contact your local dealer or our service

office.

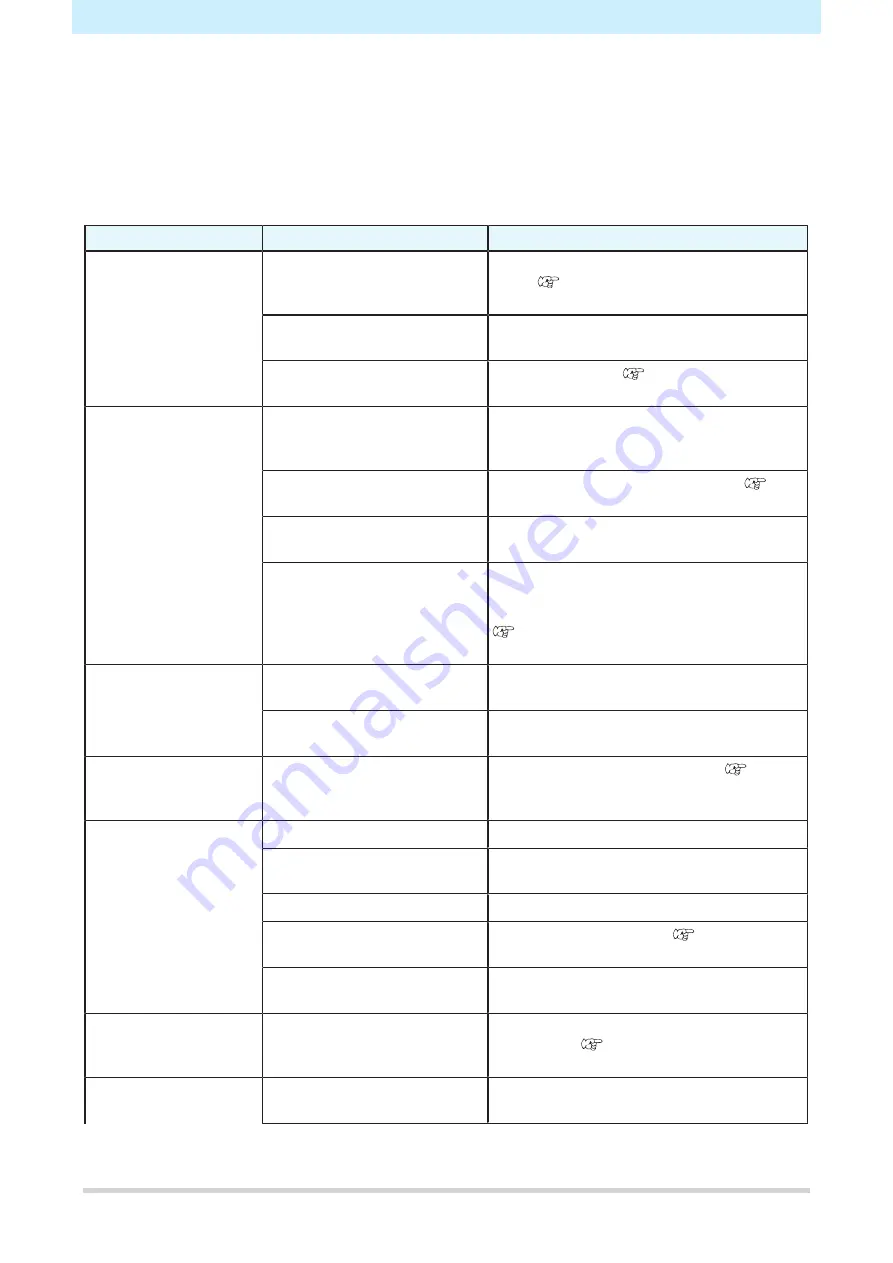

Symptom

Cause

Corrective action

The power does not turn

on.

The machine is not connected

to the power outlet by the power

cable.

Insert the power plug securely into the power

outlet.

The power cable provided is not

being used.

Use the power cable provided.

The power is not turned on.

Turn the power on.

Cutting (printing) is not

possible.

Parameters such as the plotter

name are incorrectly set in the

application.

Check the application settings.

The interface cable is not

correctly connected.

Connect the interface cable correctly.

"Connect host computer to machine."(P. 33)

The USB driver has not been

installed.

Install the USB driver using the installer.

Unidentified cause.

Cut a sample stored in the machine to identify

the cause. Executing a sample cut will clear

any data saved in the receive buffer.

"Investigating the Cause of Cutting

An error occurs when

data is sent from the

computer.

The command is incorrectly set

Adjust the command settings between the

application and plotter.

The plotter model is incorrectly

set in the application.

Set the plotter model to [CG-AR] in the

application.

Sheet detection is not

possible.

A transparent sheet or sheet

with black underside is being

used.

Disable the sheet sensor function.

Cutting forms a broken

line.

The tool holder knob is loose.

Retighten the knob on the tool holder.

The cutting blade is protruding

too far.

Adjust the cutting blade protrusion

appropriately.

Half cut is enabled.

Disable half cut in the tool conditions.

The cutting blade is chipped or

worn.

Replace with a new cutter.

The cutting blade does not

rotate smoothly.

Replace with a new holder.

The cut length differs

from the data length.

The sheet feed length changes

depending on the sheet

thickness.

Perform distance correction to correct the

discrepancy.

Offset occurs during

cutting.

The pinch rollers and grit rollers

are not gripping the sheet firmly.

Check the pinch roller and grit roller positions

to ensure that the sheet is gripped securely.

Summary of Contents for CG-100AR

Page 39: ...Chapter 1 Before Using This Machine 39 2 Shut down the computer connected to the machine 1 ...

Page 76: ...Chapter 2 Cutting 76 ...

Page 98: ...Chapter 3 Cutting Data with Register Marks 98 ...

Page 131: ...Chapter 4 Helpful Tips 131 4 Press the END key several times to exit 4 ...

Page 132: ...Chapter 4 Helpful Tips 132 ...

Page 133: ...Chapter 5 Settings This chapter Describes the individual settings FUNCTION 134 SET UP 135 ...

Page 150: ...Chapter 6 Maintenance 150 ...

Page 158: ...Chapter 7 Options 158 ...

Page 178: ...Chapter 9 Appendix 178 ...

Page 182: ...MEMO ...