- 3.4 -

Cleaning the wiper and ink caps

The ink cap prevents clogging of the head nozzle caused by dried nozzle.

The wiper wipes out ink adhered to the head nozzle.

As the device is used to plot images, the wipers and ink caps gradually become stained with ink and

dust.

Use the cotton buds to clean the ink and wiper.

Clean the wiper and the ink cap periodically so as to keep the plotter in good operation condition.

• Do not move the carriage out of the capping station by hand. Use the appro-

priate operation key to move the carriage.

STEP

1.

Push the [FUNCTION] key.

2.

Push the [ ] and [ ] key until the display gives

the indication [MAINTENANCE].

3.

Push the [ENTER] key.

[STATION] is displayed.

4.

Push the [ENTER] key.

[CARRIAGE out] is displayed.

5.

Push the [ENTER] key.

Move the carriage on the platen.

6.

Open the front cover.

7.

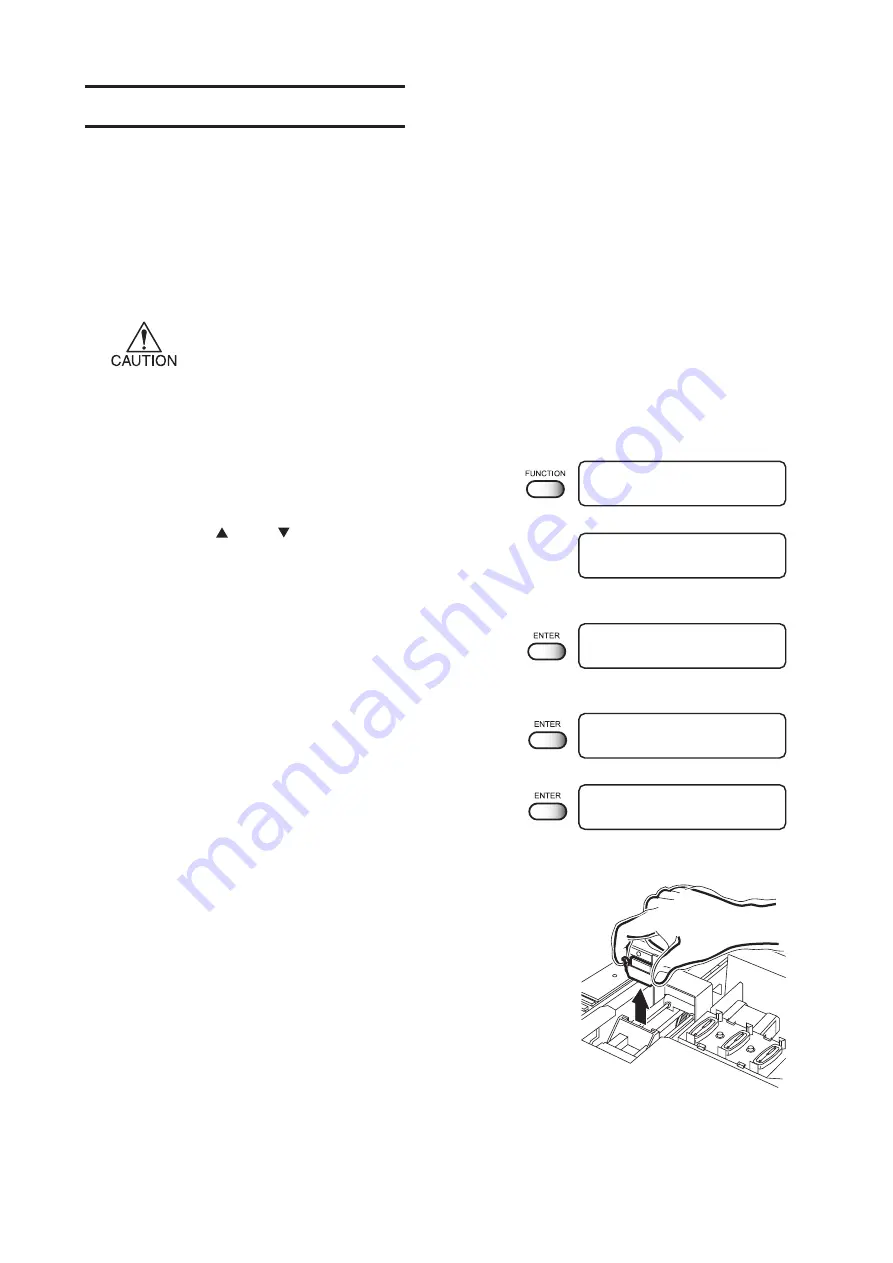

Holding the projections at both ends, draw out

the wiper.

FUNCTION

SET UP

< ENT >

FUNCTION

MAINTENANCE

< ENT >

MAINTENANCE

STATION

< ent >

STATION

MENT : CARRIAGEout

STATION

COMPLETED

: ent

Summary of Contents for JV22-130

Page 2: ......

Page 34: ... 1 18 ...

Page 86: ... 4 14 ...

Page 120: ... A 6 ...

Page 125: ......

Page 126: ...PrintedinJapan D201031 MIMAKI ENGINEERING Co Ltd 2006 ...