- 6.9 -

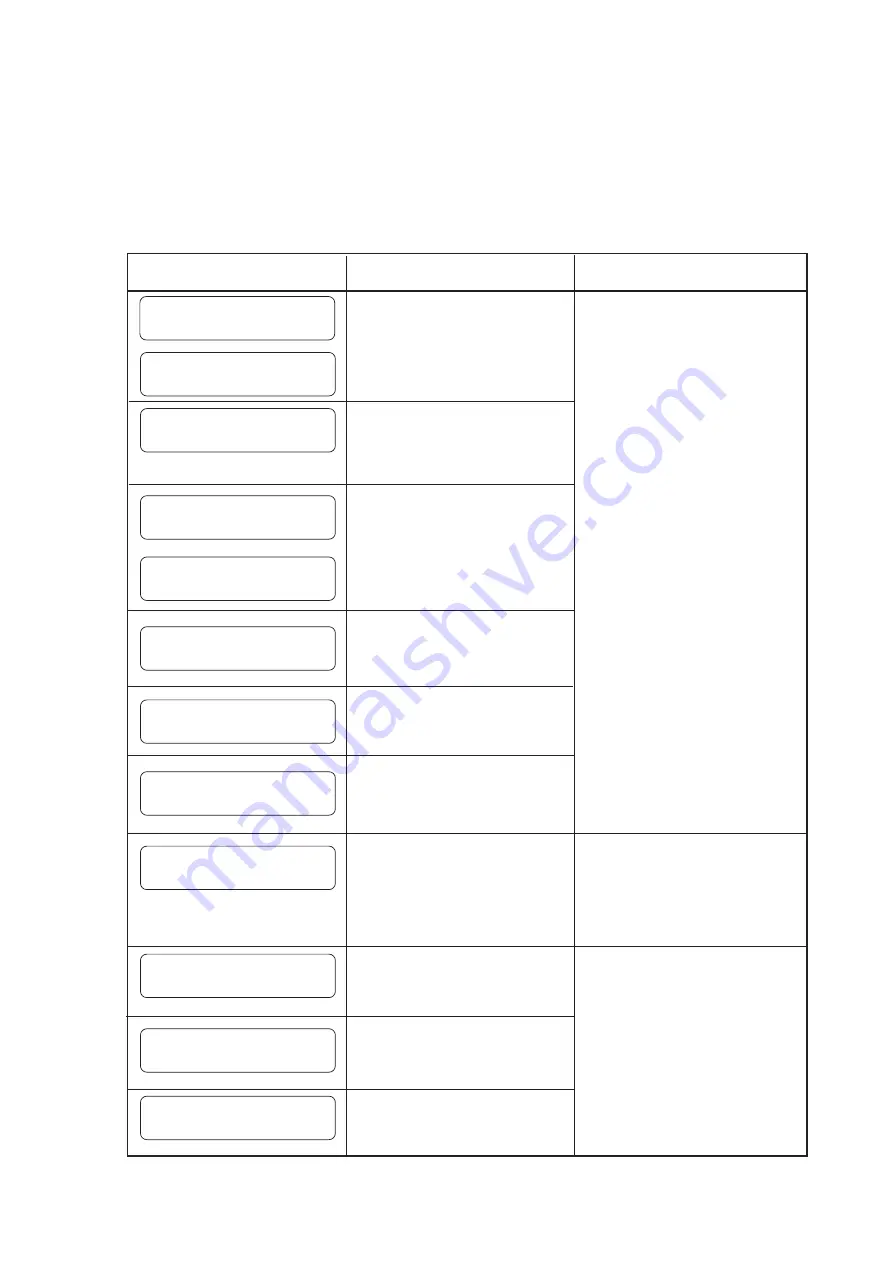

Error messages

Error messages indicates error numbers.

If any error message is given on the LCD, turn off the power to the device and turn it on

after a while.

If the same error message appears again on the LCD, contact your local MIMAKI distribu-

tor or MIMAKI office to call for service.

Error message

Cause

Corrective measure

ERROR 01

MAIN ROM

ERROR 02

MAIN RAM

ERROR 03

POWER +5V

ERROR 04

FRASH ROM

ERROR 06

D-RAM

ERROR 07

HEAD

−

−

∗

−

−

−

ERROR 08

ENCODER n

ERROR 09

HDC

ERROR 10

COMMAND

ERROR 11

PARAMETER

ERROR 20

I / F BOARD

ERROR 21

I / F NONE

Control circuit board is defective.

Control circuit board is defective.

POWER+5V

POWER+35V

Control circuit board is defective.

Head connection failure is

detected.

Trouble with detection of linear

encoder.

Control circuit board is defective.

FPGA Error

HDC Error

The device has received data

other than command data.

The interface cable used is not

in conformance with this

plotter.

A parameter outside the range

of acceptable numeric values

is received.

Improper operation has been

conducted on the operation

panel.

No I/F board is attached to the

control board.

Turn off the power to the

device an turn it on after a

while. If the same error

message appears again on the

LCD, contact your local dis-

tributor to call for service.

Securely connect the interface

cable in position. Use an

interface cable in conformance

with the standard.

Turn off the power to the

device and turn it on after a

while. If the same error

message appears again on the

LCD, contact your local dis-

tributor to call for service.

Summary of Contents for JV3-130SPII

Page 2: ......

Page 34: ...1 16...

Page 66: ...2 32...

Page 92: ...4 16...

Page 149: ......

Page 150: ...Printed in Japan MIMAKI ENGINEERING CO LTD IT FW 7 5...