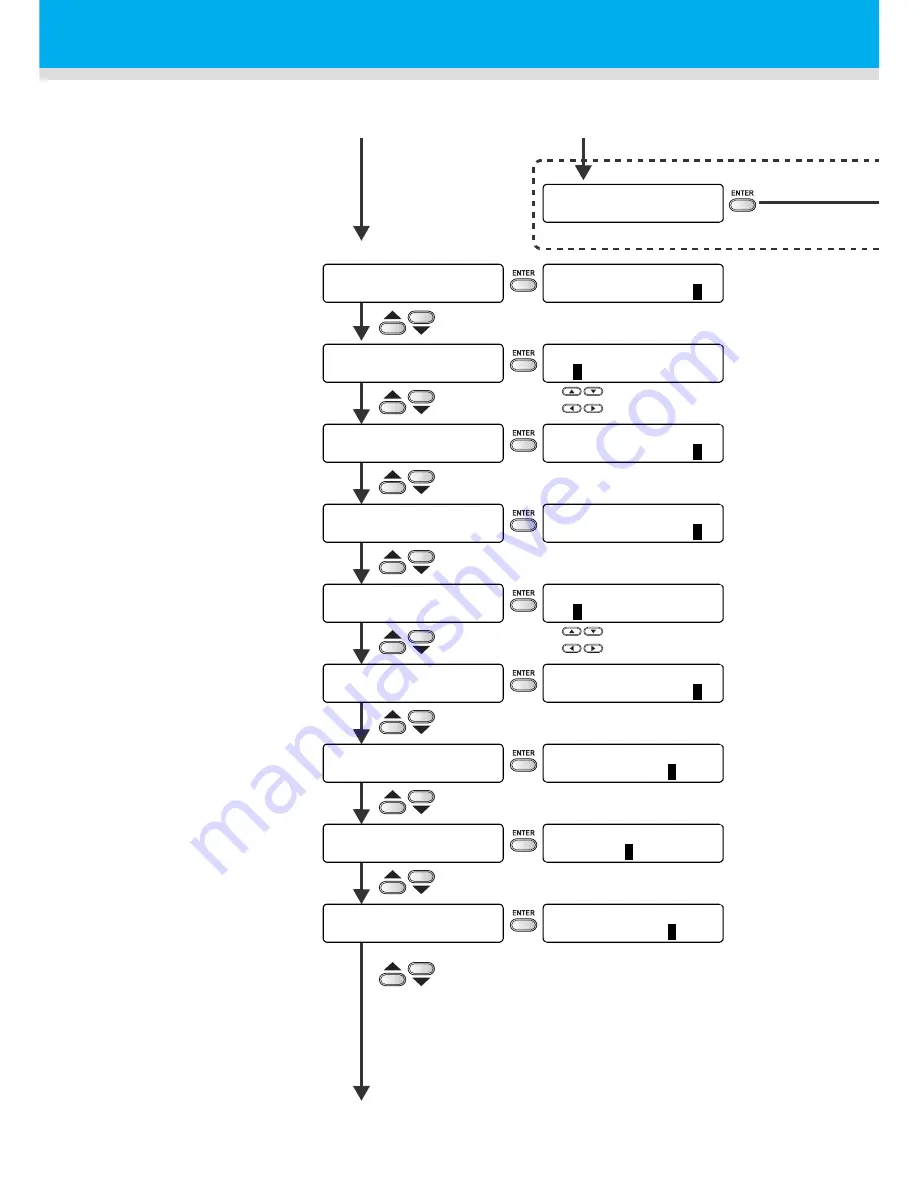

6-14

From P6-12

To P6-16

1 ~ 9

[ 1 ]

I NK L A Y ERS

< e n t >

[ 1 ] I NK L A Y ERS

S E T UP

:

1

[ 1 ]

DRY I NG T I ME

< e n t >

SCAN

: D r a w . END

0

. 0 s

:

0 s

ON / OFF

[ 1 ]

AU TO CU T

< e n t >

[ 1 ] AU TO CU T

S E T UP

:

O

F F

ON / OFF

[ 1 ]

PRE - F E ED

< e n t >

[ 1 ] PRE - F E ED

S E T UP

:

O

F F

[ 1 ]

MARG I N

< e n t >

L E F T

:

R I GH T

0

mm

:

0mm

ON / OFF

[ 1 ]

CO L OR P A T T ERN

< e n t >

[ 1 ] CO L OR P A T T ERN

S E T UP

:

O

N

LEVEL 0 ~ 3

[ 1 ]

RE F RE SH

< e n t >

[ 1 ] RE F RE SH

S E T UP

:

L

E V E L 3

OFF / WEAK / Little WEAK /

STRONG / STANDARD

[ 1 ]

V ACUUM

< e n t >

[ 1 ] V ACUUM

S E T UP

:

S

T ANDARD

10 ~ 200 %

[ 1 ]

F e e d S P E ED L E V E L < e n t >

[ 1 ] F e e d S P E ED L E V E L

L E V E L

:

1

0 %

Change the number

Move cursor

Change the number

Move cursor

[ 1 ] PR I N T MODE

Wh i t e L a y P r t

< e n t >

From P6-12

When SS21 (6+ white) ink is filled

Summary of Contents for JV33-130

Page 1: ...MIMAKI ENGINEERING CO LTD URL http www mimaki co jp D201694 16 ...

Page 7: ...vi ...

Page 99: ...3 35 Machine settings 3 Convenient use Examples of Output ...

Page 101: ...3 37 Machine settings 3 Convenient use 7 Press the key 8 Press the key several times to end ...

Page 114: ...3 50 ...

Page 147: ...Setting Routine operations 4 33 4 Routine Maintenance 8 Press the key several times to end ...

Page 185: ...6 11 Function Flowchart 6 Appendix To P 6 12 To P 6 18 To P 6 24 To P 6 25 To P 6 26 ...

Page 189: ...6 15 Function Flowchart 6 Appendix OFF LEVEL 1 3 1 Wh i t e L a y P r t SE L OF F ...

Page 201: ...D201694 16 31012012 ...