– 5.6 –

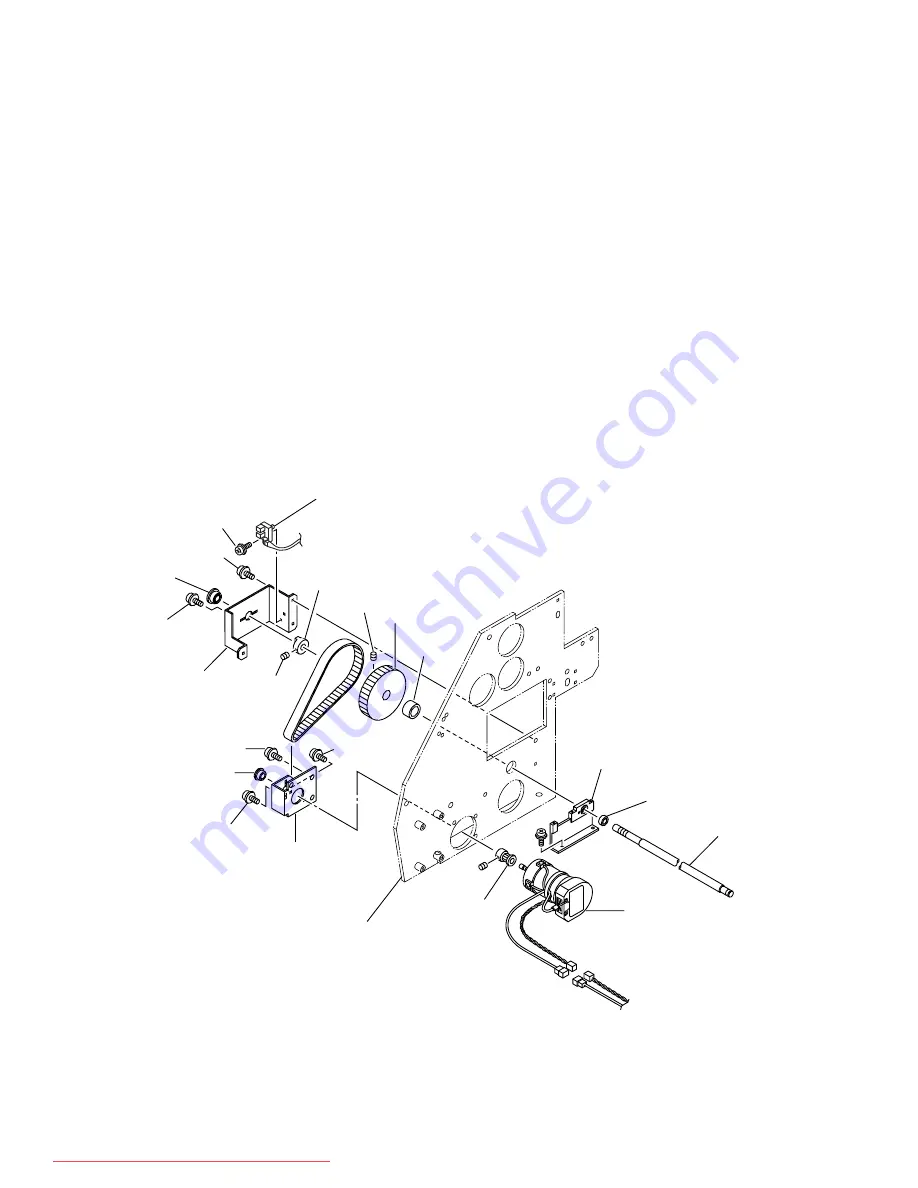

5-1-4. X-motor assy.

[Tools to be used]

•

Phillips screwdriver (No.2 for M3 to M5)

[Disassembling procedure]

1) Remove the screw (B3 x 6Ni), then remove the SL cover.

2) Remove the screw (B3 x 6Ni), then remove the YL cover.

3) Remove the left cover.

4) Loosen the screw (P4 x 8SMW) in the X-motor BKT from the left side plate.

5) Remove the screw (P3 x 6SMW) from the X-motor BKT, then remove the X-motor assy.

*

Adjust Y-timing belt : Refer to [6-2-5. Adjustment of the X-motor belt tension] P.6-11

[Assembling procedure]

•

Assembly is reverse of disassembly.

to Main PCB assy. CN20

to Main PCB assy. CN6,7

B3 x10Bk

P4 x8SMW

P3 x6SMW

P4 x8SMW

P4 x8SMW

P3 x6SMW

SSWP4

XM BKT

Bearing

X-Origin sensor assy.

Pulley stopper

SSWP4

TN15-20 Pulley

Bushing

XM BKT

Bearing

Left side plate

Bearing

Bearing holder 1

X-joing shaft

X-axis motor assy.

TN-15-160 Pulley

SSWP4

Downloaded From ManualsPrinter.com Manuals

Summary of Contents for JV4-130

Page 2: ...Downloaded From ManualsPrinter com Manuals ...

Page 8: ... vi Downloaded From ManualsPrinter com Manuals ...

Page 9: ... 1 1 CHAPTER 1 OVERVIEW OF MAINTENANCE Downloaded From ManualsPrinter com Manuals ...

Page 18: ... 1 10 Downloaded From ManualsPrinter com Manuals ...

Page 19: ... 2 1 CHAPTER 2 EXPLANATION OF OPERATION Downloaded From ManualsPrinter com Manuals ...

Page 23: ... 2 5 Main PCB block diagram Downloaded From ManualsPrinter com Manuals ...

Page 38: ... 2 20 Downloaded From ManualsPrinter com Manuals ...

Page 59: ... 4 1 CHAPTER 4 MAINTENANCE MODE Downloaded From ManualsPrinter com Manuals ...

Page 130: ... 4 72 Downloaded From ManualsPrinter com Manuals ...

Page 131: ... 5 1 CHAPTER 5 DISASSEMBLING ASSEMBLING PROCEDURE Downloaded From ManualsPrinter com Manuals ...

Page 152: ... 5 22 Downloaded From ManualsPrinter com Manuals ...

Page 153: ... 6 1 CHAPTER 6 ADJUSTMENT Downloaded From ManualsPrinter com Manuals ...

Page 154: ... 6 2 6 1 Adjusting item list Downloaded From ManualsPrinter com Manuals ...

Page 168: ... 6 16 Downloaded From ManualsPrinter com Manuals ...