© 2014 MIMAKI ENGINEERING CO.,LTD.

7.3

P.4

R.1.5

INSTALLATION GUIDE > Outputting Plots > Performing the Initial Ink Fill

Model

JV400-130/160LX

Issue 2011.02.15 Revised 2013.10.10 F/W ver.

2.50

Remark

1.5

7.3 Performing the Initial Ink Fill

Working Procedures

1. Remove the head cover.

2. Select the ink set type to fill.

3. Insert all ink cartridges.

When all ink cartridges are inserted, filling operation starts.

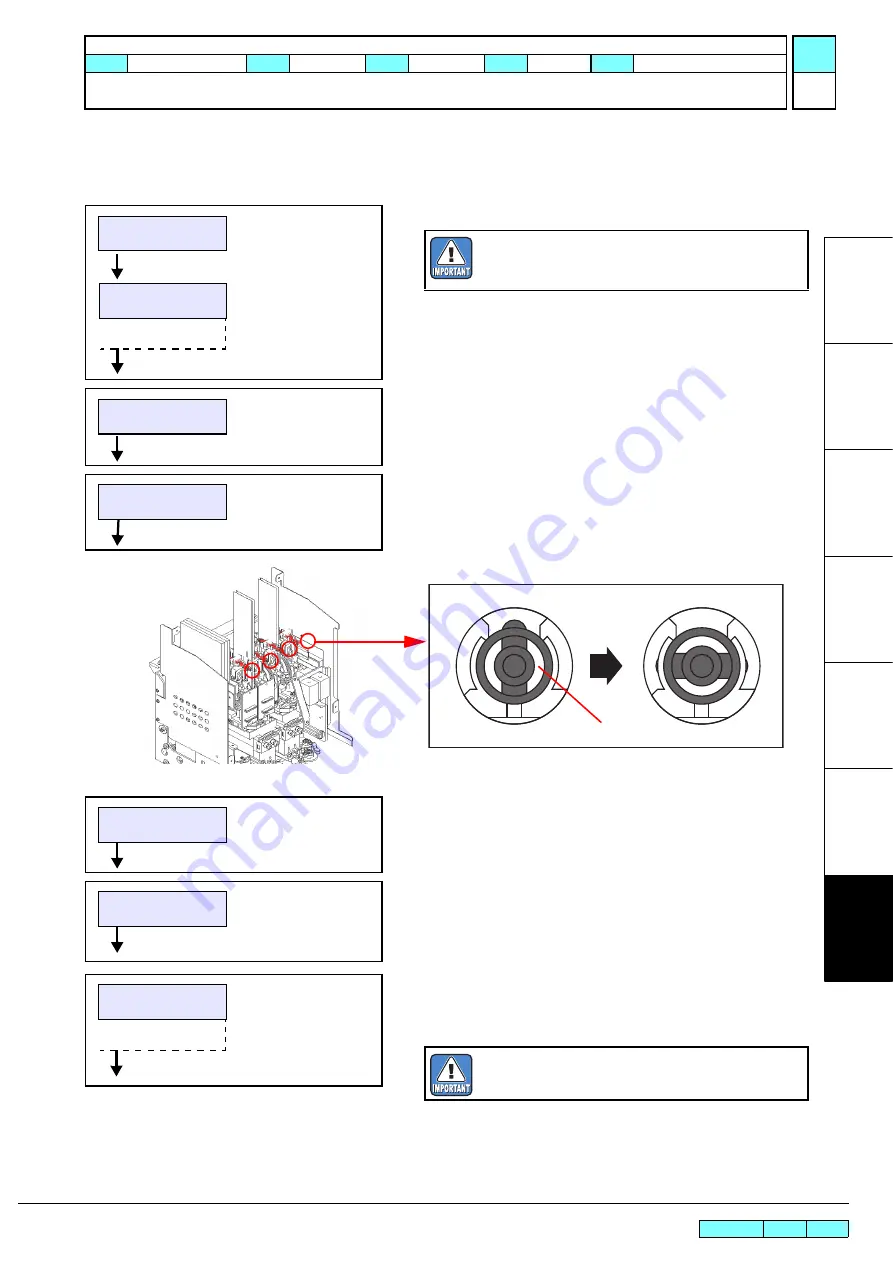

4. Rotate the valve opening shaft 90 degrees with a flathead

screwdriver.

After rotating it, press the [ENTER] key.

5. Wait until the filling operation has been completed.

6. Remove air.(Filling head air port

)

With the [

] key, move to the air purge sequence.

(When you press the [

] key, air purge work is not performed

and the machine moves to the cleaning operation.(to step 15.)

7. Select a damper on which you perform air purge.

[

] [

]: Select

[ENTER]: Register

INK TYPE

:LX101

INK SET

:4Color

Example for LX101

6Color

W

Select the ink set which is selected in chapter 5.”Ink

Set”.

When select different ink set, it is not filled normally.

Set a cartridge

:MMCCYYKK

When the cartridge is set,

“_” is displayed.

AIR PG VALVE OPEN

COMPLETED [ENT]

valve opening shaft

rotate 90 degrees

** FILL UP **

PLEASE WAIT

AIR PG

END < >START

1234----

----5678

SELECT DAMPER

12345678

This does not mean that you can perform air purge

on all air purge ports you selected at the same time.

Summary of Contents for JV400-130LX

Page 49: ......

Page 50: ...D500698 22 30042014 2013 MIMAKI ENGINEERING CO LTD KF FW 2 50...