1-17

1

Before Use

3

4

5

6

Media

Usable media sizes and notes for handling are described.

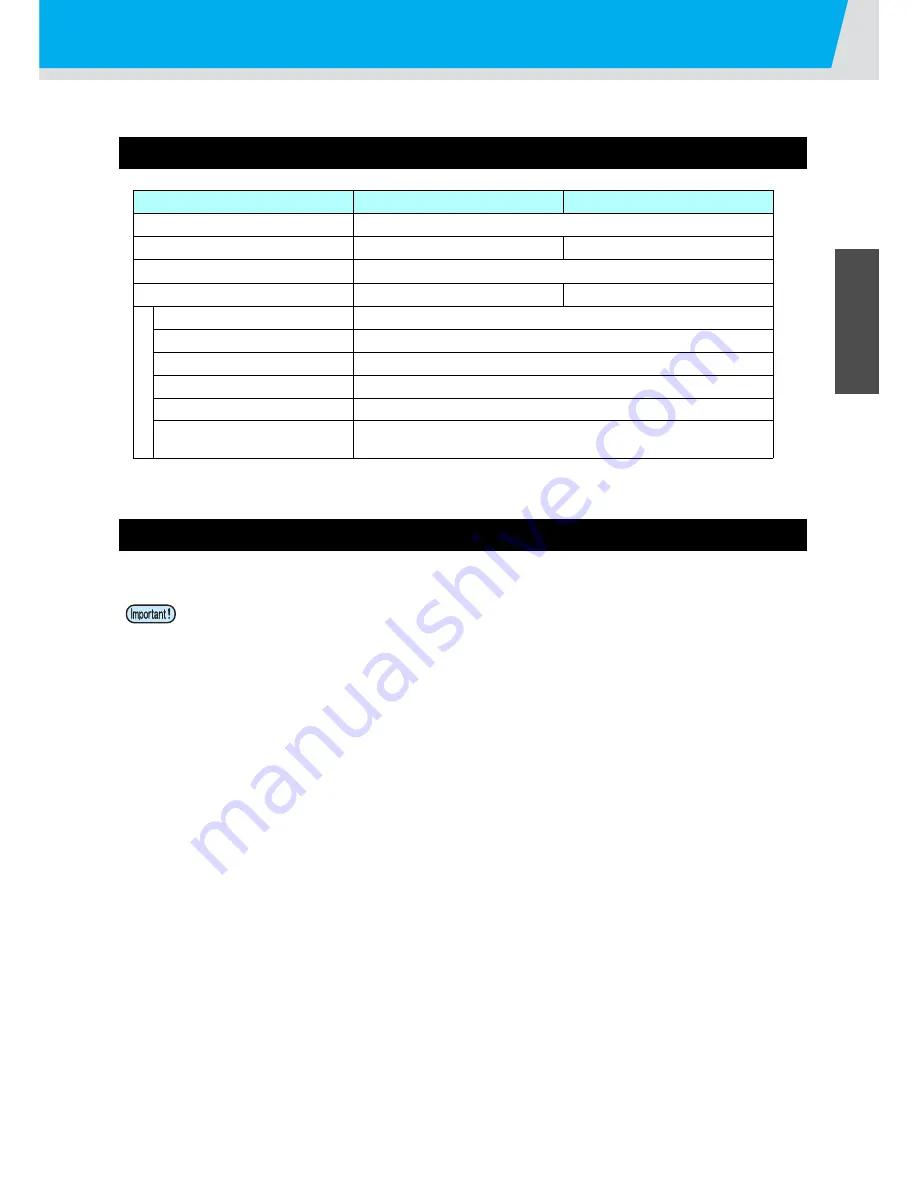

Usable sizes of media

Caution in handling of medias

Pay attention to the followings for handling of medias.

Model

JV400-130SUV

JV400-160SUV

Type of Recommended media

Tarpaulin/Weatherproof PVC/FF

Maximum width

1371mm

1620mm

Minimum width

210mm

Maximum printing width

1361mm

1610mm

Ro

ll medi

a

Thickness

0.2mm or less

Roll outside diameter

φ

180mm and less

Roll weight

25kg and less

Roll inside diameter

3 or 2 inches

Side printed

Side facing outward

Roll end treatment

The roll end is gently fixed to the core with weak-adhesive tape or weak

glue for easy removal.

•

When handling media, wear the gloves.

If you touch the media with your bare hand, the media may be stained due to fingerprints or oil of your

finger. Be careful about it.

•

Do not leave the media with the heater ON for a long time.

Waviness may occur on the media and it may cause media clogging.

•

Use media recommended by MIMAKI to ensure reliable, high-quality printing.

Set the heater temperature to meet the characteristics of the media.

•

Set the temperature of the Pre-heater, Print heater and Post-heater according to the type and

characteristics of the media used.

Automatic temperature setting can be made on the operation panel by setting the profile on the

dedicated RIP. For setting on the RIP, refer to the instruction manual for your RIP.

•

Pay attention to the expansion and contraction of the media.

Do not use media immediately after unpacking. The media can be affected by the room temperature

and humidity, and thus it may expand and contract.

The media have to be left in the atmosphere in which they are to be used for 30 minutes or more after

unpacked.

•

Do not use curled media.

This may result in paper jamming.

If a regular-sized coated sheet of media is rolled and stored, the coated side has to face outside.

•

Be careful to dusts on the edge face of the medium.

Some rolls have dusts contained in the package gathered on the edge surface of the roll. If you use as

it is, the drawing quality may be degraded due to nozzle missing or ink drops. Be sure to set the roll

after removing dusts adhering on the edge face of the roll.

Summary of Contents for JV400-130SUV

Page 1: ...MIMAKI ENGINEERING CO LTD URL http eng mimaki co jp D202394 17 Original instructions ...

Page 58: ...2 28 ...

Page 73: ...3 15 1 1 3 Convenient use 5 6 9 Press the key several times to end the setting ...

Page 100: ...3 42 ...

Page 162: ...5 20 ...

Page 179: ...Function Flowchart 6 17 Appendix 6 ...

Page 187: ...Function Flowchart 6 25 Appendix 6 ...

Page 192: ...6 30 ...