5-15

Chapter 5 Troubleshooting

1

2

2

2

5

ERROR 432

Take-UP Connect

Take-up device connection destination

error

• Turn off the power button to the machine

and turn it on after a while.

• If the same error message appears

again, contact your local distributor to call

for service.

ERROR 433

Feeding Connect

Feeding device connection destination

error

ERROR 436

Take-UP Fuse Err

Take-up fuse blown

ERROR 437

Feeding Fuse Err

Feeding fuse blown

ERROR 442

Take-UP Voltage

Abnormal voltage of the take-up unit

ERROR 443

Feeding Voltage

Abnormal voltage of the take-up unit

ERROR 44d

STATION POS ERROR

Abnormal station position

ERROR 44e

UV UNIT FAN ERROR

The UV unit fan does not operate.

ERROR 46b

TAKE-UP ENC WRONG

An error occurs in the take-up encoder.

ERROR 46c

FEEDING ENC WRONG

An error occurs in the feeding encoder.

ERROR 50a

Y ORIGIN

Y-origin could not be detected.

ERROR 50c

MEDIA WIDTH SENSOR

The media width has not been detected

correctly.

• Check the media set position.

• Clean the media sensor. (

ERROR 50f

L-SCALE BLACK

Abnormal linear scale.

• Turn off the power button to the machine

and turn it on after a while.

If the same error message appears

again, contact your local distributor to call

for service.

ERROR 516

MEDIA SET POSITION R

The media is set outside the proper area.

• Check the media set position.

ERROR 516

MEDIA SET POSITION L

ERROR 531

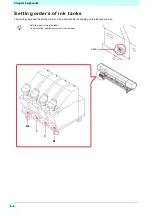

INKTNK SENS:MCYK

The weight balance is abnormal.

• Make sure the ink supply unit is

connected to the machine.

• Check if any weight or load is taken on

the ink tank.

• Implement the "Tank Calibration" of the

Maintenance menu, and perform the

correction of the balance.

• If the same error message appears

again, contact a distributor in your district,

our office, or our call center.

ERROR538

CHECK MEDIA SET POS.

The media is not set in the correct position.

• Check the media set position.

ERROR 607

CAP CLEANING

Time to clean the cap

• Perform the station maintenance, and

clean the cap.

ERROR 618

TANKlevelH

:1234

The sub tank sensor High does not change

though a certain amount of ink has been

consumed.

• Perform “SUBTANK” of the maintenance.

(

Even if you perform, it may be displayed,

contact your local distributor to call for

service.

ERROR 61a

InkOverflow

:1234

Ink has entered the air tank.

Message

Cause

Solution

Summary of Contents for SIJ-320UV

Page 1: ...MIMAKI ENGINEERING CO LTD URL http mimaki com D202809 13 Original instructions ...

Page 14: ...xiii Warning labels ...

Page 28: ...1 14 Chapter 1 Before Use ...

Page 98: ...4 26 ...

Page 116: ...5 18 Chapter 5 Troubleshooting ...

Page 122: ...Chapter 6 Appendix 6 6 ...