4-7

4

2

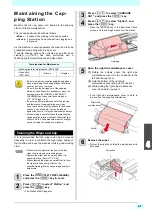

Maintaining the Cap-

ping Station

Maintain the ink cap, wiper, etc. located in the capping

station. (Station maintenance)

The ink cap and wiper function as follows.

•

Wiper

: It wipes off ink sticking to the head nozzles.

•

Ink cap

: It prevents the head nozzles from clogging due

to dryness.

As the machine is used repeatedly, the wiper and ink cap

gradually become dirty with ink, dust, etc.

If nozzle missing cannot be corrected even after head

cleaning (

P.2-19) has been performed, use a

Washing liquid for maintenance and clean stick.

Cleaning the Wiper and Cap

It is recommended that the wiper and cap be cleaned

frequently in order to maintain the high image quality of

the machine and keep the machine itself in good working

order.

1

Press the

(TEST PRINT/CLEANING)

,

and press the

key in Local.

2

Press

to select “Station”, and

press the

key.

• The Station MENU appears.

3

Press

to select “CARRIAGE

OUT”, and press the

key.

4

Press

to select “Station”, and

press the

key.

• Press the [ENTER] key in the Execution Check

screen, and the carriage moves over the platen.

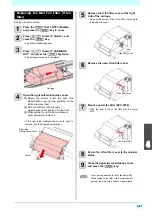

5

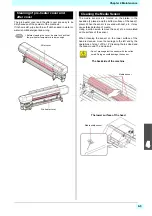

Open the right side maintenance cover.

(1)

Rotate the screws under the right side

maintenance cover (for two positions) to the

left and remove them.

(2)

Hold the bottom of the right side

maintenance cover and pull it to the front.

(3)

While pulling the right side maintenance

cover downward, remove it.

• If the right side maintenance cover is hard to

remove, use the supplied screwdriver.

6

Remove the wiper.

• Pull out the wiper by holding the protrusions at its

both ends.

Tools required for Maintenance

• Washing liquid for maintenance (SPC-0568)

• Clean stick

(SPC-0527)

• Gloves

• Goggles

• Be sure to wear the supplied goggles and gloves

when maintaining the capping station.Otherwise,

you may get ink in your eyes.

• Do not move the carriage out of the capping

station by hand.When it is desirable to move the

carriage, press the [FUNC2] (TEST PRINT/

CLEANING) key to execute the carriage-out.

(

P.4-7Steps 1 to 2)

• Be sure to perform maintenance for the ink cap

and the wiper of capping station every day.

If you leave it dirty, dirt may adhere to the nozzle

surface, or, dust and dry ink may be rubbed

against the nozzle. It may cause discharge defect.

• While working, be careful to avoid subjecting the

capping station to direct sunlight. Ultraviolet light

will cure UV ink. Take measures to block sunlight,

such as closing the curtains on windows.

• When work is complete at the end of the day,

clean the wipers and surrounding areas.

• Replace the wiper with a new one when it is

extremely dirty or bent.(

• When cleaning the wiper, be careful that lint from

the clean stick does not get left on the

wiper.Remaining lint may cause image quality to

deteriorate.

Carriage

Right side

maintenance

Screw

Projection

Summary of Contents for SIJ-320UV

Page 1: ...MIMAKI ENGINEERING CO LTD URL http mimaki com D202809 13 Original instructions ...

Page 14: ...xiii Warning labels ...

Page 28: ...1 14 Chapter 1 Before Use ...

Page 98: ...4 26 ...

Page 116: ...5 18 Chapter 5 Troubleshooting ...

Page 122: ...Chapter 6 Appendix 6 6 ...