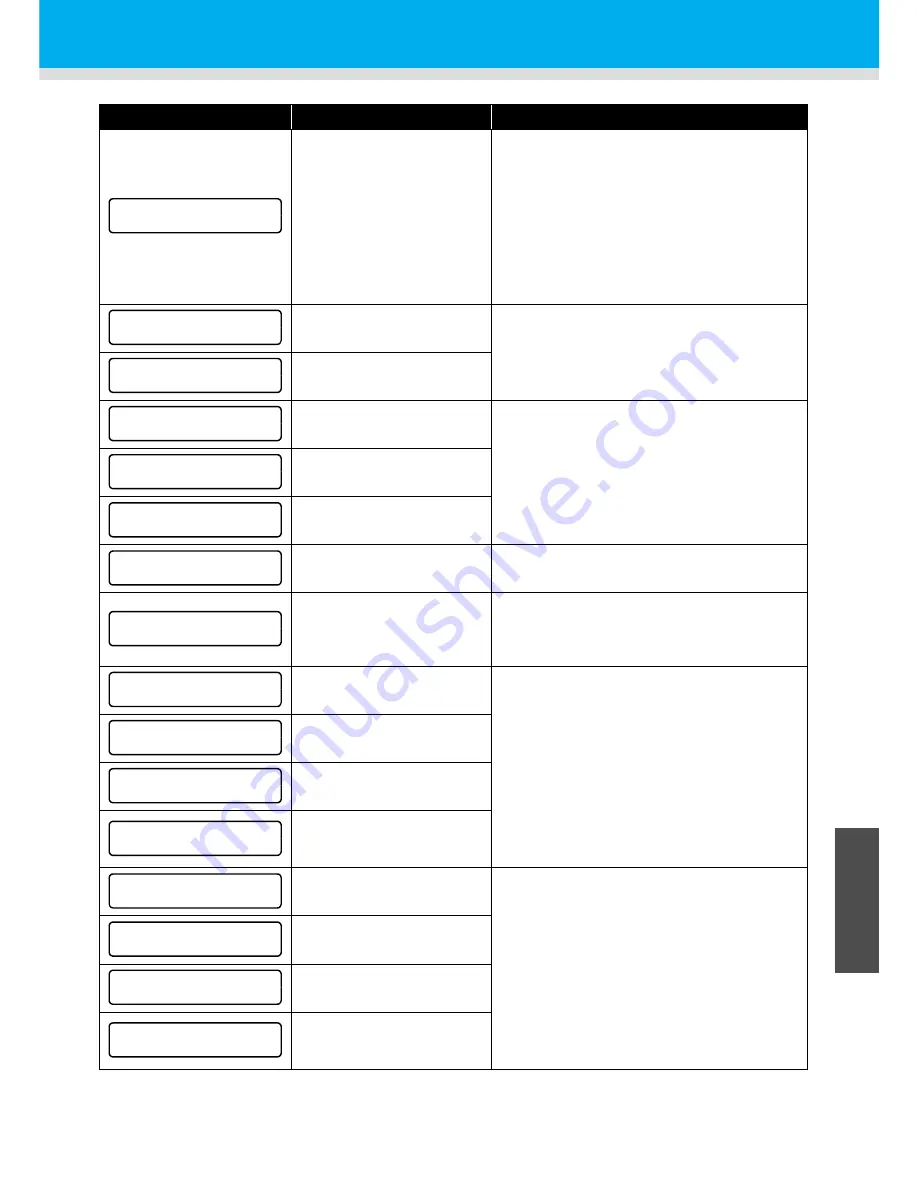

Warning/Error Messages

5-15

1

2

3

4

5

T

roubleshooting

Error messages

Cause

Solution

The media width could not be

detected.

The reason may be one of the followings:

• The positions of the left and the right ends of the

media you set are not proper.

• The position of the taking-up tension bar is not

proper.

• The position of the feeding tension bar is not

proper.

If the same error message appears again even if

you have made the machine proper status, contact

our service office or the distributor in your region.

The Y origin has not been

detected.

Turn OFF the power to the machine and turn it ON

again after a while.

If the same error message appears again, contact

our service office or the distributor in your region.

A flushing performing time out

error occurred.

An error has occurred on the

firmware.

Turn OFF the power to the machine and turn it ON

again after a while.

If the same error message appears again, contact

our service office or the distributor in your region.

Sub tank sensor error has

been detected.

Ink has overflowed.

Ink leakage has been

detected.

After removing all 2L eco cases from slots, contact

our service office or the distributor in your region.

An error of the valve solenoid

power voltage of the ink slot

has been detected.

Turn OFF the power to the machine and turn it ON

again after a while.

If the same error message appears again, contact

our service office or the distributor in your region.

Ink supply from the 2L ink pack

could not be performed.

Turn OFF the power to the machine and turn it ON

again after a while.

If the same error message appears again, contact

our service office or the distributor in your region.

Ink could not be absorbed.

An error occurred in EEPROM

embedded in the head.

Data communication error

occurred between the head

and the UHC board.

At belt origin detecting, a

control abnormality occurred.

Turn OFF the power to the machine and turn it ON

again after a while.

If the same error message appears again, contact

our service office or the distributor in your region.

A control abnormality of the

belt encoder occurred.

The linkup with the media

feeding system failed.

A system abnormality of the

media feeding system was

detected.

E R R OR 5 0

M E D I A D E T E C T

E R R OR 5 1

Y O R I G I N

E R R OR 6 0

F L U S H I N G n n n n

E R R OR 9 0

F / W s s

E R R O R 1 4 0

T A N K S E N S OR n n n n n n n n

E R R O R 1 4 0

I N K O V E R F L OW

E R R O R 1 4 2

I N K L E A K

E R R O R 1 4 3

I N K S L O T S O L E N O I D

E R R O R 1 4 7

I N K S U P P L Y

( n )

E R R O R 1 4 8

S U C T I ON n n n n n n n n

E R R O R 2 0 0

H E A D ME MO R Y

E R R O R 2 0 4

S E R I A L I Z E R

E R R O R 1 3 0

B E L T OR I G I N

E R R O R 1 3 1

B E L T E N C O D E R

E R R O R 1 7 0

X L I N K - U P n n n n

E R R O R 1 7 1

X U N I T n n n n

Summary of Contents for TEXTILE JET TX1800B

Page 1: ...MIMAKI ENGINEERING CO LTD URL http www mimaki co jp D202080 14 ...

Page 13: ...xii 1 2 3 4 5 6 How to Read This Operation Manual ...

Page 14: ...xiii ...

Page 40: ...1 26 ...

Page 80: ...2 40 ...

Page 196: ...5 30 ...

Page 205: ...Function Flowchart 6 9 1 2 3 4 Appendix 6 To P 6 10 To P 6 14 To P 6 20 ...

Page 220: ...6 24 ...

Page 221: ...D202080 14 29122011 ...