1-18

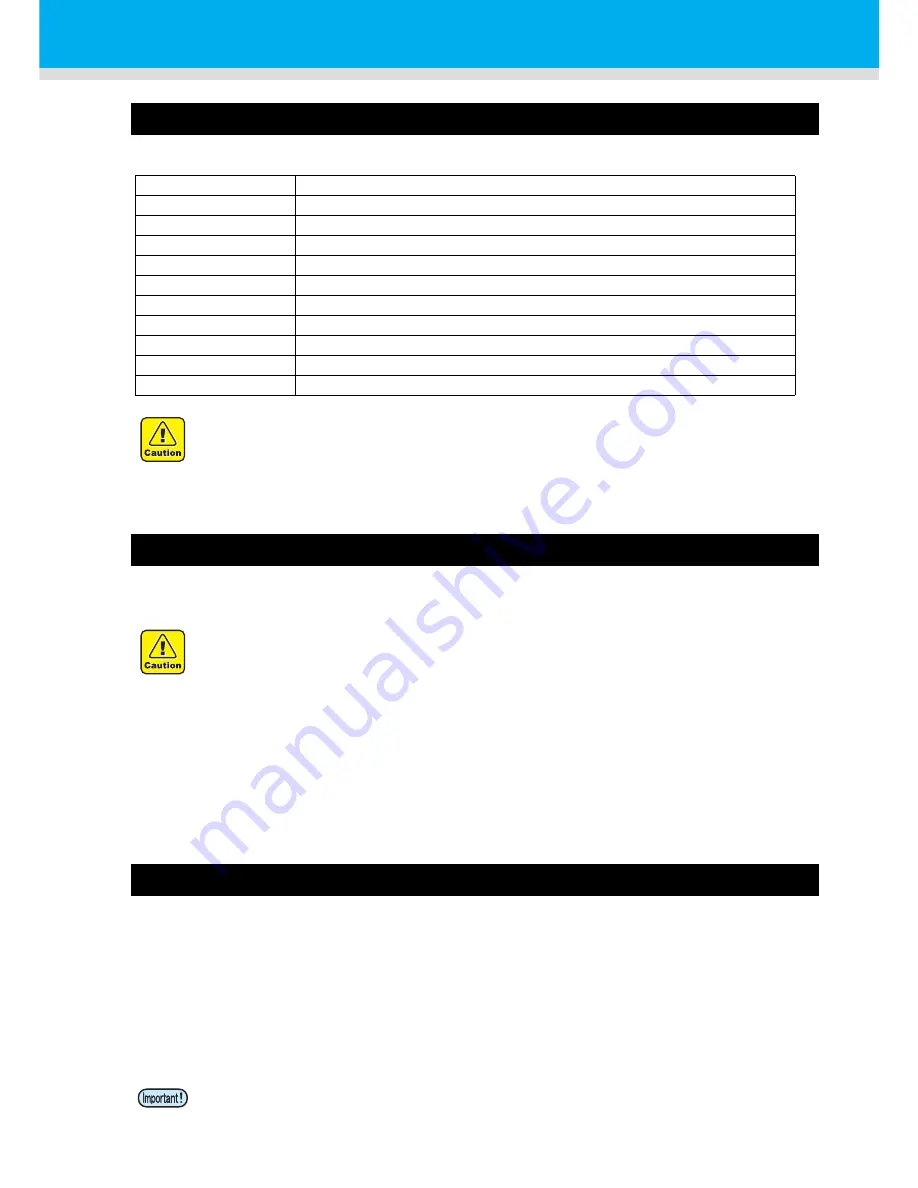

Media

Usable Sizes of Media

The media usable in this machine is as below:

Precautions in handling the fabric

Here, procedures and precautions in handling the usable fabric are explained.

Fully understand the contents and use depending on the kind or the characteristic of fabric.

Limited media

With the following media, correction from the plotter is difficult.

When using any of the following media, perform test printing to determine whether it can be used or not.

• Hight stretch fabric (Stretch materials, vertically extendable knit,etc.)

• Materials which become largely extendable when getting wet by printing.

• Materials with large width variations.

• Materials which present partial wrinkles of slacks when being spread on a flat surface or materials which are

totally curved.

• Materials with large take-up shift at the ends of media when rolled.

• Roll media with a paper tube whose strength is insufficient and which bends when attached to a feeding unit.

Maximum width

1860mm

Minimum width

210mm

Maximum printing width

1850mm

Thickness

7mm or less

Roll outside diameter

400mm

Roll weight

44kg or less

Roll inside diameter

2 ~ 3 inch

Print side

Regardless of faces out and in

Taking up direction

Regardless of faces out and in

Roll end treatment

Light-adhesive tape is used to allow the paper to be removed from the core with ease.

Setting position

Based on the center

• The belt encoder unit to feed the media correctly is attached on the right side of the media feeding

system. Be careful not to make the media hanging over the position of 25mm from the right edge of

the media feeding system.

• If you print with the media hanging over the belt encoder unit, the media cannot be fed correctly, and

it may adversely affect the printing quality. Be careful especially when using wider media (the media

with 1800mm and more width).

• Use pre-processed fabric recommended by MIMAKI.

• When setting the fabric, be sure to adjust the head height. Other wise, the fabric and/or the head can

be damaged.

• Do not use fabric with curled edges. Use of such a fabric may cause contact with the print head

nozzle, resulting in inferior ink discharge.

• Do not use fabric whose edges are remarkably loose in comparison with the center. Crease occurs at

the fixing section, which may come into contact with the head nozzle face.

• Thick hard fabric cannot be used for unattended operation. When using a denim-like fabric, skew

check must be performed by the operator. Once skew starts, the self-restoration action of the fabric

itself is disabled. If the fabric is neglected, skew advances to the right or left end of the belt which may

cause head jam.

• Brushed fabric is unavailable for Fabric edge guide. The peeling sensor react to the brushed part, and

not able to feed fabric properly.

• Even when using media other than described above, be sure to print by optional test data. After

checking the printing result, judge whether it can be used or not.

Summary of Contents for TEXTILE JET TX1800B

Page 1: ...MIMAKI ENGINEERING CO LTD URL http www mimaki co jp D202080 14 ...

Page 13: ...xii 1 2 3 4 5 6 How to Read This Operation Manual ...

Page 14: ...xiii ...

Page 40: ...1 26 ...

Page 80: ...2 40 ...

Page 196: ...5 30 ...

Page 205: ...Function Flowchart 6 9 1 2 3 4 Appendix 6 To P 6 10 To P 6 14 To P 6 20 ...

Page 220: ...6 24 ...

Page 221: ...D202080 14 29122011 ...