2-28

8

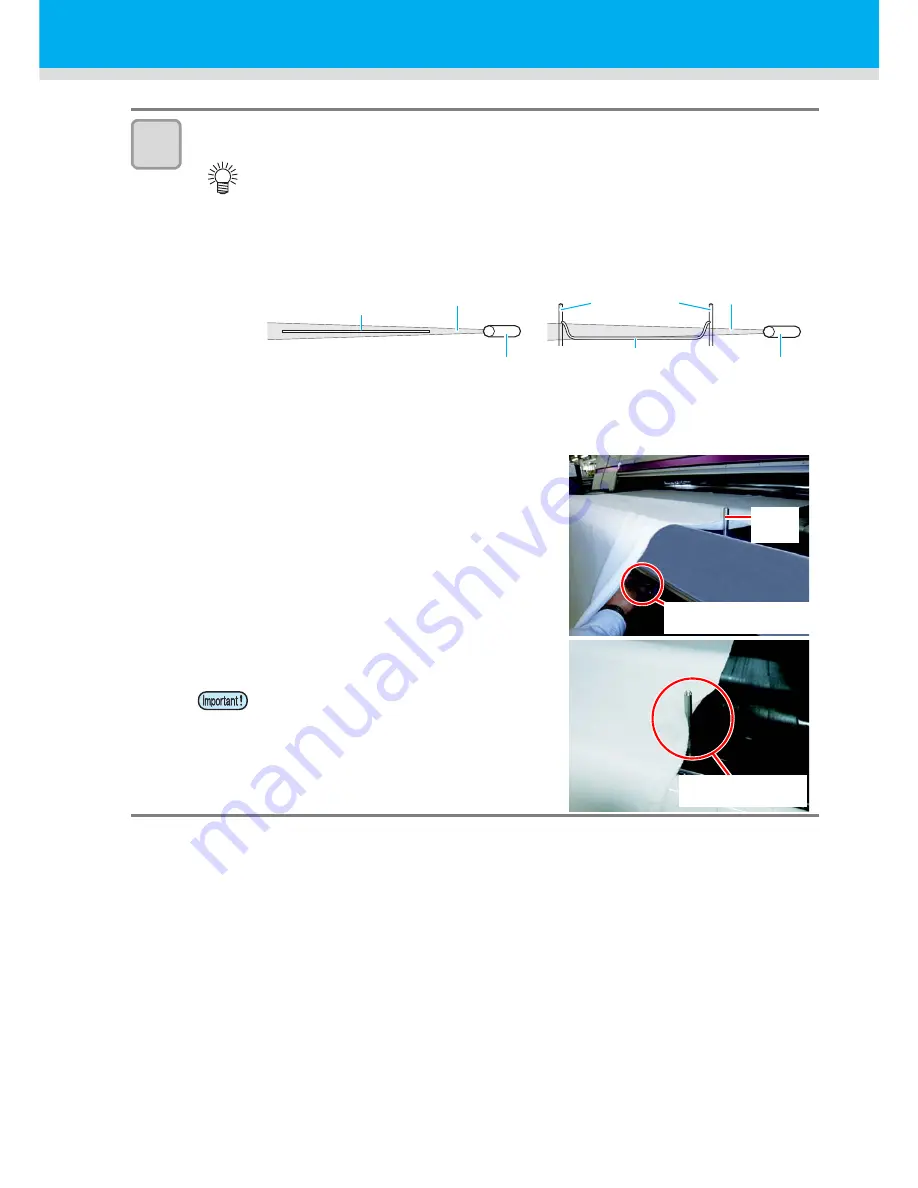

Adjust the fabric guide to slant the media end.

• For the wider media (1000mm and more), if wrinkle or waviness may occur on the media at peeling, it is

not required to use the fabric guide.

(1)

Loosen the right and left adjustment finger screw

and move to right and left.

• The fabric guide moves to right and left.

(2)

Align the fabric guide position so that it is in the

status indicated in the photo.

(3)

Adjust both of right and left of the fabric in the same

way.

• This machine checks the media position by detecting media with the peeling sensor.

• The peeling sensor can detect the media when the media shades light emitting from the

sensor.

• When using firm media or wider media, the media cannot be detected in some cases

because light emitting from the sensor is not shaded much. When using such media, to

make the media can shade the sensor light by slanting the media edge with the fabric guide

in order to detect the media easily.

• Make the amount of pressing the fabric guide

against the fabric edge about 10mm. If you

press it too much, the media may be taken up

on the roll with the fabric edge folded.

Peeling

sensor

Sensor light

Media

Fabric guide

Sensor light

Media

Peeling

sensor

Right and left

adjustment finger screw

Fabric

guide

Fold back the fabric

end surface a little.

Summary of Contents for TEXTILE JET TX1800B

Page 1: ...MIMAKI ENGINEERING CO LTD URL http www mimaki co jp D202080 14 ...

Page 13: ...xii 1 2 3 4 5 6 How to Read This Operation Manual ...

Page 14: ...xiii ...

Page 40: ...1 26 ...

Page 80: ...2 40 ...

Page 196: ...5 30 ...

Page 205: ...Function Flowchart 6 9 1 2 3 4 Appendix 6 To P 6 10 To P 6 14 To P 6 20 ...

Page 220: ...6 24 ...

Page 221: ...D202080 14 29122011 ...