- A.2 -

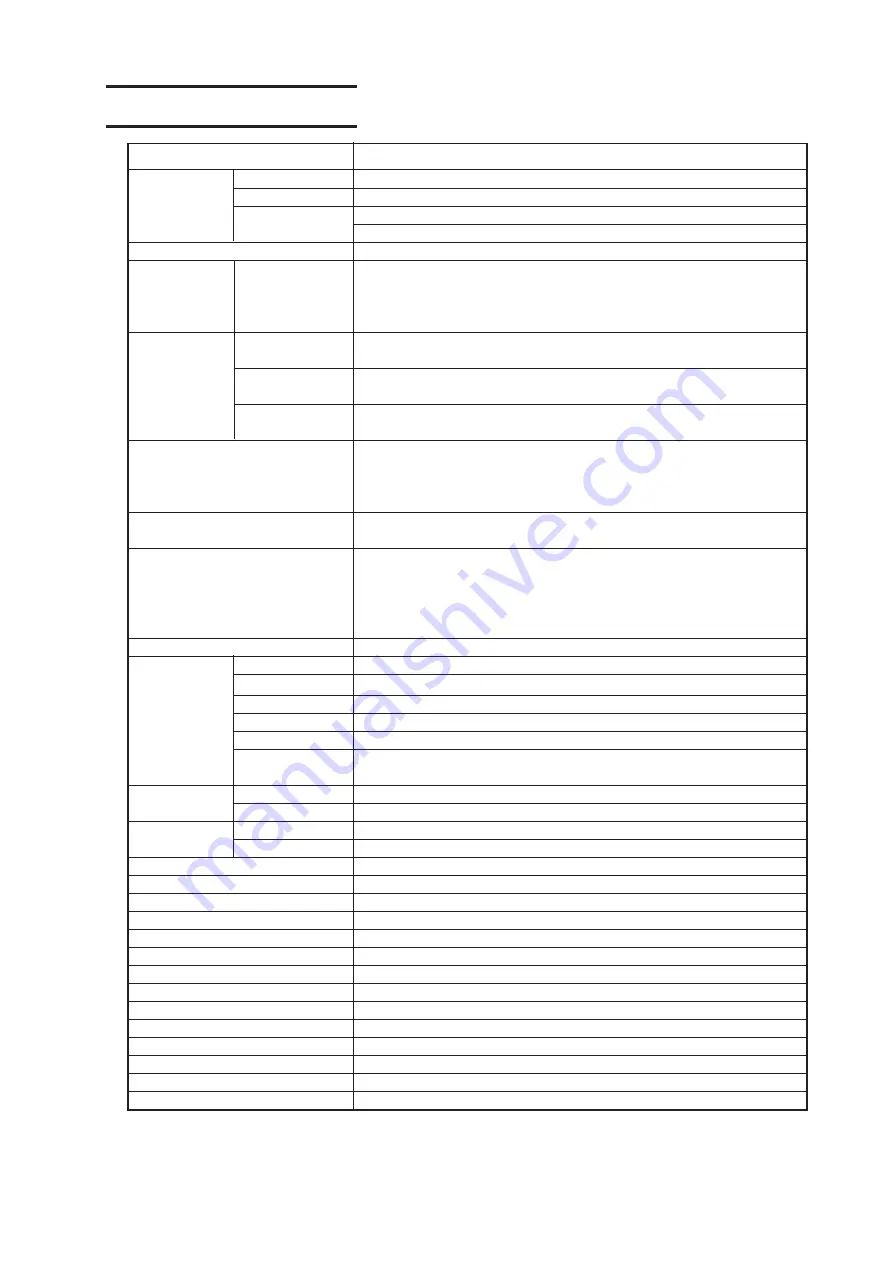

BASIC SPECIFICATIONS

Item

Tx2-1600

Printing head

Method

Piezo-electric drop-on demand

Specification

Eight-heads (4 x 2 lines, Stagger arrangement)

Nozzle

High speed printing : 360 nozzles for each color

Printing speed

Two independent printing : 180 nozzles for each color

Resolution

360 , 540, 720 dpi

Drawing mode

Resolution

360 x 360 dpi : 2 / 4 / 8passes, Unidirection / bidirection

Pass

360 x 540 dpi : 3 / 6 / 12 passes, Unidirection / bidirection

Printing direction

360 x 720 dpi :4 / 8 / 16 passes, Unidirection / bidirection

720 x 720 dpi : 4 / 8 / 16 passes, Unidirection / bidirection

Ink type

Acid dye ink

Color (Gray, Black, Cyan, Magenta, Yellow, Light Cyan, Light Magenta,

Color

Blue, Red)

Disperse dye ink

Color (Gray, Black, Cyan, Magenta, Yellow, Light Cyan, Light Magenta,

Blue, Light Blue)

Reactive dye ink

Color (Gray, Black, Cyan, Magenta, Yellow, Light Cyan, Light Magenta,

Blue,Orange, Red, Golden Yellow)

Delivery system of ink

Proprietary system with low ink detection sensor

Correction of the remaining amount of ink provided.

INK END detection function is provided.

Ink cartridge replacement method

Capacity of ink cartrige

220 cc

±

10 cc per cartrige (x1 or x2)

About 200cc can be used for each cartridge.

Fabric type

The following cloths are excluded.

•

Cloths which become elastic with water

•

Cloths with high elasticity

•

Curled or folded cloths

•

Cloths with a low firing point (when the optional drying unit is used)

Max. Printing width

Width 1620 mm

Fabric size

Thickness

7.0 mm or less

(Roll fabric)

Roll outside diameter

φ

180 mm or less

Roll weight

15 Kg or less

Roll inside diameter

1.35 Inch, 2 Inch, 3 Inch

Printing surface

Printing can be made on either side.

Roll end treatment

Light-adhesive tape is used to allow the paper to be removed from the

core with ease.

Margin

Left end

10 mm

±

0.5 mm

(Roll fabric)

Right end

10 mm

±

0.5 mm

Distance accuracy

Absolute accuracy

Whichever the larger one of

±

0.5 mm or

±

0.3 % of the designated

Reoroducibility

Whichever the larger one of

±

0.5 mm or

±

0.3% of the designated

Perpendecularity

±

0.5 mm / 1000 mm

Fabric skew

5 mm or less / 10 mm variable (Centering ON)

Head height adjustment

1.1 mm to 10 mm variable from the platen surface

Cutting of fabric

Cutter function not provided.

Fabric delivery

Take-up device as standerd (inside winding / outside winding selectable)

Waste ink tank

Waste ink hose standard (Waste ink tank not provided)

Interface

IEEE1394, IEEE1284

Command

MRL-1E (ESC/PV.1 base) Mimaki original command

Noise during standby

Less than 56 dB

Noise during continuous printing

Less than 66 dB

Noise during discontinuous printing

Less than 70 dB

Safety Standard

FCC ClassA, UL1950

Power

AC 100 - 240 V

±

10% (Auto voltage)

Power consumption

450 W or less

Summary of Contents for TextileJet Tx2-1600 Series

Page 2: ......

Page 20: ...xvi...

Page 88: ...2 12...

Page 146: ...5 10...

Page 153: ......

Page 154: ...D200595 2 20 08032002...