- 1.5 -

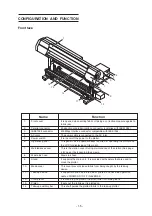

CONFIGURATION AND FUNCTION

Front face

Name

Function

1.

Front cover

It is opened when setting fabric or taking a corrective measure against a

fabric jam.

2.

Parallel connector

Bi-directional parallel interface connector (complies with IEEE1284)

3.

IEEE1394 connector

400Mbps interface connector compatible with IEEE1394.

4.

AC inlet

The power cable is connected to the AC inlet.

5.

Power switch

It turns on/off the power to the plotter.

6.

Operation panel

This panel has the operation keys required for operating the plotter and

the LCD for displaying set items, etc.

7.

Maintenance cover

This is the station cover. During maintenance of the station (See page

4.8), open it by loosening the screws.

8.

Waste ink hose

Waste ink hose

9.

Stand

It supports the main unit. It is provided with casters that are used to

move the plotter.

10.

Meda cover

This cover prevents loose fabric from being caught by the take-up

device.

11.

Take-up device

It supports to wind up the roll fabric printed, and have the operation

named FORWARD / OFF / REVERSE.

12.

Clamp lever

It is made to go up-down the pinch roller for holding fabric.

13.

Platen

It puts out the fabric as it is plotted on.

14.

Take-up auxiliary bar

This shaft guides the plotted fabric to the take-up plotter.

1

2

3

4

6

5

7

8

9

10

14

13

12

11

Summary of Contents for TextileJet Tx2-1600 Series

Page 2: ......

Page 20: ...xvi...

Page 88: ...2 12...

Page 146: ...5 10...

Page 153: ......

Page 154: ...D200595 2 20 08032002...