- 4.10 -

Periodical cleaning of the wiper

Cleaning the wiper

The wipers are provided for cleaning the heads. As the device is used to plot images, the wipers

gradually become stained with ink and dust. Clean stained wipers.

The wiper is separately available from your local distributor or our office.

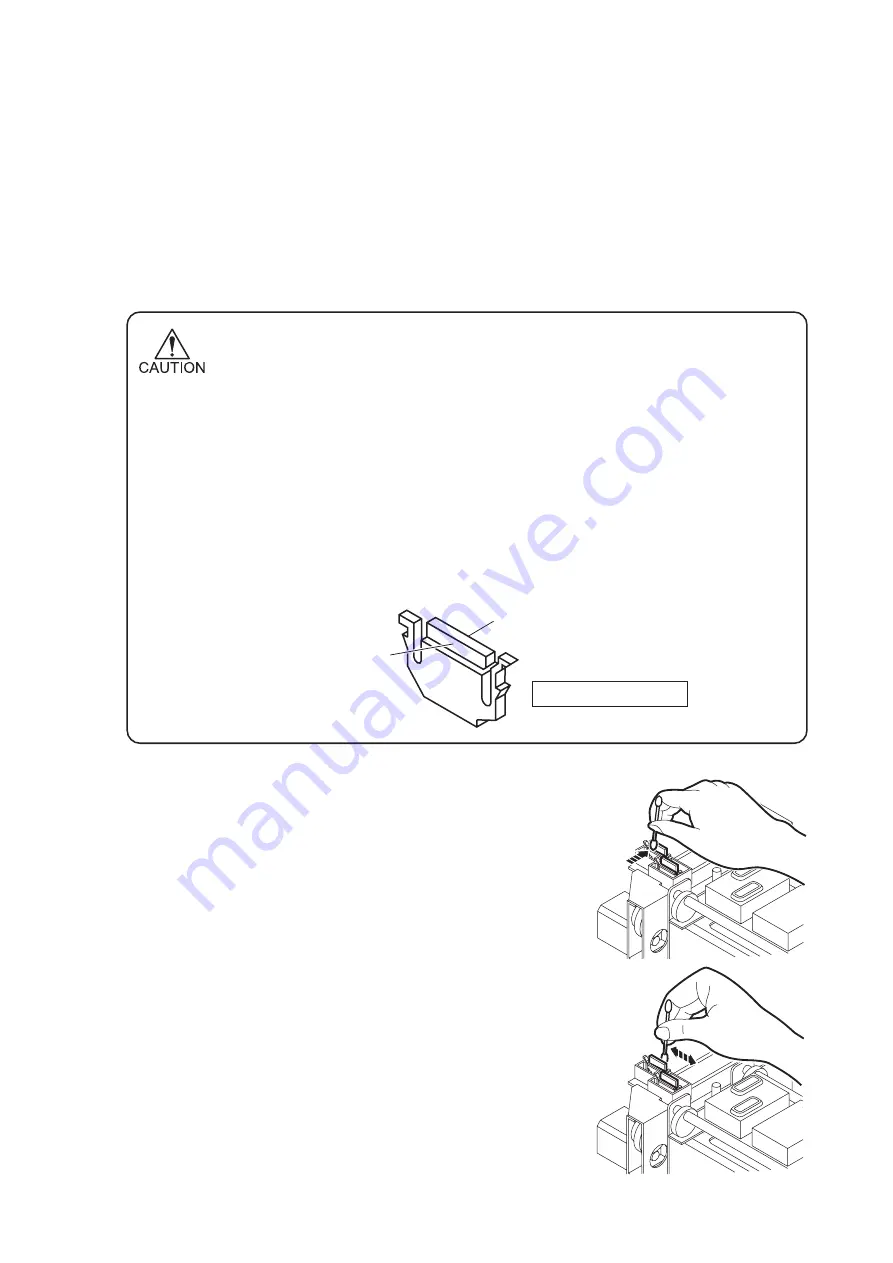

Notes on handling the wipers

•

Avoid contacting the rubber portion of the new wiper. Contacting it will result in

clogged nozzl

•

Clean the two wipers at a time.

•

The front side of each wiper is made of felt, and the rear side is made of rubber.

Do not rub the felt side with a swab. Instead, press the swab against the felt side

surface to remove dirt. Rubbing the felt side surface will make it fluffy and result

in clogged nozzle. Wipe ink off the rubber side surface with a swab.

•

When executing this function, the carriage will come out of the capping station. If

the carriage is left in the aforementioned state for an extended period of time, the

nozzles can be clogged. Once the replacement of the wiper and the cleaning of

the caps have been completed, immediately push the [ENTER] key to allow the

carriage to return to the capping station.

STEP

1.

Move the carriage.

Execute the station maintenance [CARRIAGEout]. (Refer to

step 1 to 7 on page 4.8)

2.

Open the maintenance cover.

3.

Clean up the wiper as described below.

4.

Execute steps 8 to 9 of the station mainte-

nance [CARRIAGEout] on page 4.9.

Felt surface

Capping station side

Rubber surface

Do not rub the

felt surmace

Rubber surface

Summary of Contents for TextileJet Tx2-1600 Series

Page 2: ......

Page 20: ...xvi...

Page 88: ...2 12...

Page 146: ...5 10...

Page 153: ......

Page 154: ...D200595 2 20 08032002...