3. Maintenance Procedure

16

Continuing to use the dirty platen will prevent proper feeding of the media. It will also cause dried ink and

attached dust to rub against the head nozzle surface and lead to print defects (e.g., nozzle clogging,

deflection).

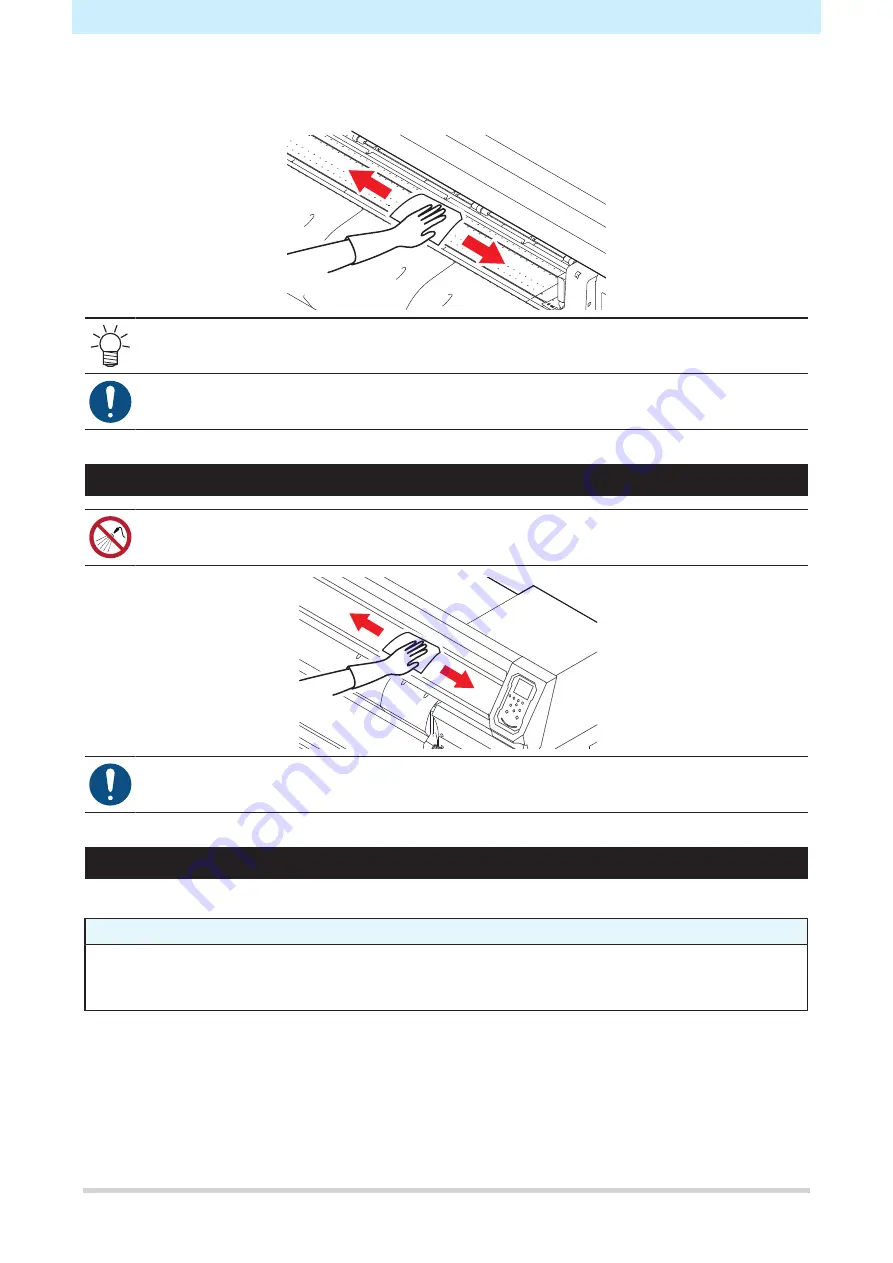

• The grooves in which the media holder slides and the media is cut are susceptible to dust

accumulation. Remove any debris carefully.

• For heavy soiling, wipe using a soft cloth soaked in dilute detergent and thoroughly wrung out.

Cover (Exterior) Cleaning

• Do not allow liquids to get inside the product. Otherwise there is a risk of failure, electric shock,

or fire.

• For heavy soiling, wipe using a soft cloth soaked in dilute detergent and thoroughly wrung out.

When Not in Use for Extended Periods

Clean as follows if the product is not used for one week or longer:

Check beforehand

Is [Near End] or [Ink End] displayed?

• Maintenance liquid and ink is aspirated during the washing operation. Washing is not possible if an

error occurs during this process. Replace with new ink.

1

On the LOCAL mode screen, select [MENU] > [Maintenance], then press the [ENTER] key.

• The Maintenance menu is displayed.

2

Select [Station] > [Custody Wash], then press the [ENTER] key.

• The carriage moves over the platen.