For safe operation

8

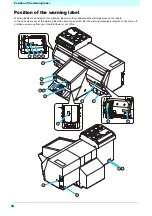

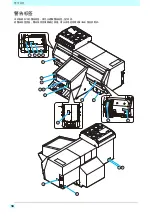

Cautions on Installation

Cleaning

• After using this machine long time, foreign materials

and dust may be gathered on the conductive and

insulating parts, causing electric leakage. Periodically

clean such parts.

• For cleaning, do not use compressed air because it

scatters foreign materials and dust, which may cause

malfunctions when put inside the conductive parts. Be

sure to use vacuum cleaner to vacuum off foreign

materials and dust.

• Do not use the machine in a place where there is a

possibility of being wet, or electricity may leak.

• Electrical leakage may lead to electrical shock of

personnel or fire.

• To prevent accidents, be sure to carry out periodic

inspections and replace periodic replacement parts.

Periodic exchange parts

• There are some parts which must be periodically

replaced. Contract with distributors or dealers for

maintenance.

Adjusting the level

• Keep this machine horizontal.

Firing and smoking

• Touching hot parts such as the LED UV with

combustible materials may cause firing and/or

smoking.

Leaving combustible materials under the LED UV unit

for a couple of minutes may also cause firing and/or

smoking.

• After this machine is used long time, foreign materials

or dust gathered may cause electrical leakage, or

insulation deterioration may cause firing and/or

smoking. Periodically clean this machine and replace

the deteriorated parts after the insulation resistance.

• After this machine is used long time, screws or others

on the conductive parts may be loosened, causing

firing and/or smoking. Periodically tighten the screws.

• If abnormalities such as a strange odor, a smoking or a

spark burn occurred, turn the power off and call our

office immediately.

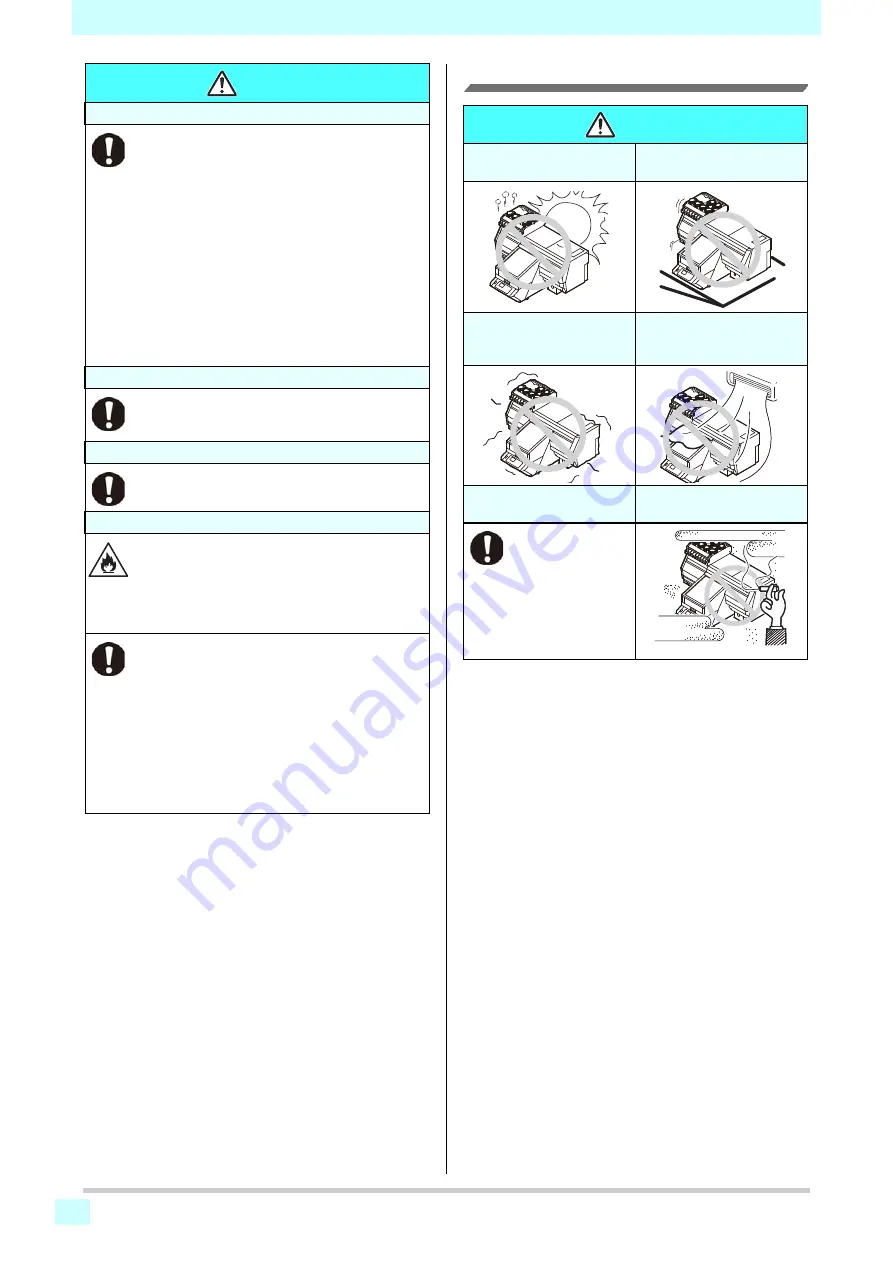

CAUTION

CAUTION

A place exposed to direct

sunlight

On an inclined surface

A place that vibrates

A place exposed to direct air

flow from an air conditioner

or the like.

A place where temperature or

humidity varies significantly

Around a place where fire

is used

•Use the machine

under the following

environmental

conditions:

• Operating environment:

20 to 30 °C

(68 to 86 °F)

35 to 65 % (Rh)

Summary of Contents for UJF-6042MkII Series

Page 13: ...13 1 2 2 2 2 2 1 1 50 2 4 3 120 MIMAKI...

Page 14: ...14 MIMAKI LED UV UV 1 3 LED UV LED UV LED UV 1 2 MIMAKI SDS...

Page 16: ...16 LED UV LED UV 20 30 68 86 F 35 65 Rh...

Page 17: ...17 1 2 2 2 2 2 1 1 1...

Page 18: ...18 MIMAKI 2 3 4 7 8 5 9 6 8 1 5 10 1 2 5 7 1 10 11...

Page 20: ...MK D203134 12 20042017 MIMAKI ENGINEERING CO LTD 2016...