4.6.5.1

Digital inputs (PR 5900/12)

Depicted: Terminal coding and internal circuitry

2K

87

3V

0

2K

87

3V

0

2K

87

3V

0

2K

87

3V

0

CH 1

+ −

CH 2

+ −

CH 3

+ −

CH 4

+ −

2K

87

3V

0

2K

87

3V

0

2K

87

3V

0

2K

87

3V

0

CH 1

+ −

CH 2

+ −

CH 3

+ −

CH 4

+ −

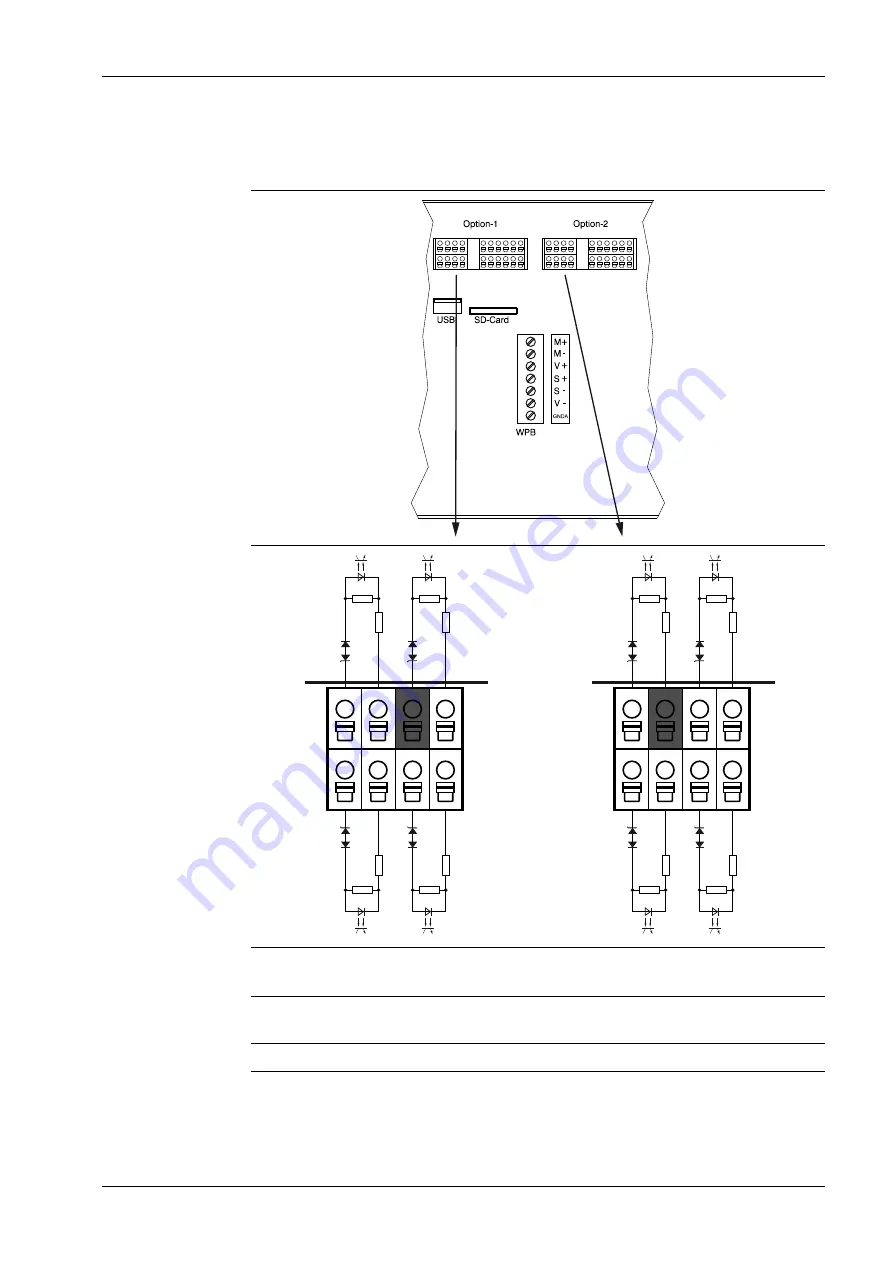

Coding for option 1 and option 2

Terminal strip:

Insert the coding pin into the slot in the position marked in gray in the

image.

Terminal:

Remove (nip of) the relevant coding nib.

4 Device installation

Process Controller Maxxis 5 PR 5900

Minebea Intec

EN-85

Summary of Contents for Maxxis 5

Page 137: ......