3. Device description | 14

3 Device description

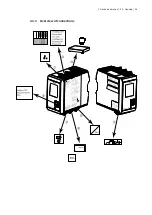

3.1 Transmitter types

3.1.1 General information

The transmitters in the PR 5215 series come in 9 expansion stages. Subse

quent expansion of the expansion stage is not possible. The respective type is

clearly designated by the corresponding number.

All of the devices are equipped with a touchscreen.

3.1.2 PR 5215/00

This type includes

–

3 digital inputs and outputs

–

a port for the analog weighing electronics (ADC)

–

a supply voltage connection

–

a RS-485 interface

–

a network port

See also Chapter