User Manual of DH-300/400 Full Automatic Soldering Robot

25

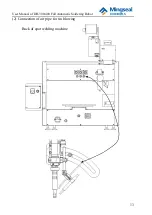

2.5 Equipment Commissioning

Check the E-stop switch and the equipment wiring, and turn on the power

switches of the motion control system and welding system of the spot welding

machine when the E-stop switch is screwed out and the wiring is correct. After

the motion control system of the spot welding machine is powered on, LED

nixie tube starts flashing. Four “-” are displayed on the nixie tube after it stops

flashing, which indicates that the program initialization is completed. Press the

Reset button to reset the machine. After the reset is completed, the task number

(default: 0) is displayed on the nixie tube. In this state, communication can be

made with PC or the handheld programmer, and tasks can be downloaded onto

the slave computer after graphic teaching through PC or the handheld

programmer. After task downloading is completed, perform graphic simulation

through the “Simulation” function of PC or the handheld programmer, and

observe whether the operating track of the spot welding machine is correct. In

simulation state, the motion system will operate, but the tin feeding system will

not operate, so actual welding will not be carried out.

Notes: (1)

The welding function is shielded by the spot welding machine

during commissioning of the full automatic soldering robot.

(2) Do not use the serial port line of the handheld programmer to

connect PC; otherwise PC may be damaged.