User Manual of DH-300/400 Full Automatic Soldering Robot

29

delay operation according to the set time. The initial setting is no this

function.

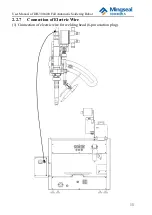

3.1.5 Reference Point Adjustment

This function realizes the reference point adjustment of the existing tasks. If the

reference point of the workpiece to be welded needs adjustment, it can be

realized through this function. The adjusted reference point is simultaneously

shifted according to the adjusted value together with the starting point of the

task.

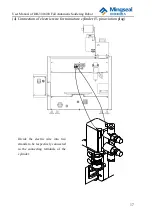

This function can be executed only when there are tasks. The adjustment range

of reference point is ±99.9mm. If the adjustment range of reference point is

exceeded, limit error will be prompted. The solution is to adjust the reference

point again.

Operation process:

Task selection

Reference point (The reference point is raised by a certain

height from the starting point according to the set value)

Press “Cylinder ↓”, and then use X→, X←, Y↑, Y↓, Z↑

and Z↓ to adjust X-axis positive direction, X-axis negative

direction, Y-axis positive direction, Y-axis negative

direction, Z-axis positive direction and Z-axis negative

direction respectively, meanwhile the current adjustment

value of reference point is displayed on LED in mm, and

the adjustment unit can be set according to Function 3; if

any direction button is pressed continuously, there will be

the function of continuous adjustment.

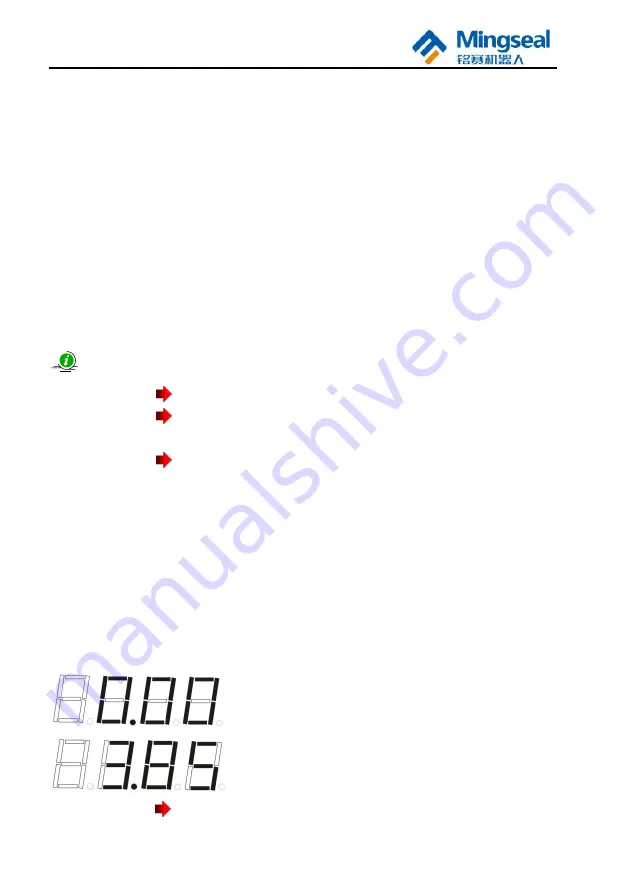

Display status of nixie tube:

Adjustment status of reference point

Adjustment of reference point is completed

OK (Adjustment of reference point is valid and saved)