User Manual of DH-300/400 Full Automatic Soldering Robot

54

at 380°C.

3.

Clean the soldering iron with the cleaning sponge. The cleaning sponge

shall be kept clean. Please do not add more water or be too dry. If more

water is added in the cleaning sponge, the oxidation rate of the welding tip

will be increased. If the cleaning sponge is too dry, the tin coating and the

chromium coating on the welding tip surface will be destroyed.

4.

When the welding tip is not in use, the soldering iron shall not be in the

high temperature state for a long time. If the welding tip is in the high

temperature state, the soldering flux on the welding tip will be converted

into an oxide to weaken greatly the heat conduction function of the

welding tip and accelerate the oxidation.

5.

When the welding tip is out of service, new tin layer shall be added after

cleaning to prevent it from being oxidized.

3.3.6 Maintenance of Soldering Bit

Inspection and cleaning method of soldering bit

1.

Set the temperature to 250°C.

2.

After the temperature is stable, clean the soldering bit with the cleaning

sponge, and inspect the status of soldering iron.

3.

If the tin coating of soldering bit contains the black oxide, new tin layer

can be plated, and then clean the soldering bit with the cleaning sponge.

Repeatedly clean in this way until the oxide is removed thoroughly, and

then plate new tin layer.

Note: Never get rid of the oxide on the soldering bit with the file.

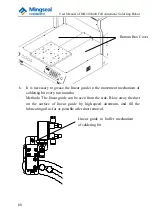

Recovery method of non-wetting soldering bit

1.

Remove the soldering bit from the soldering pencil rod of the machine

after the soldering bit is cooled.

2.

Get rid of dirt and oxides on the tin plating surface of the soldering bit

with 80# polyurethane abrasive foam or 100# emery paper.