User Manual of DH-300/400 Full Automatic Soldering Robot

65

6. Maintenance

1. Please keep the product surface clean and dry, and do not operate it in an

environment which is humid or has corrosive gas. If there is any dirt on

the product surface, please clean it in time.

2. It is necessary to turn off the power supply after use each time.

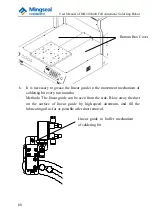

3. It is necessary to grease the linear guides in the X-axis, Y-axis and Z-axis

parallel moving mechanism every two months.

Methods:

1) Z axis: Remove the Z-axis enclosure, wipe clean the surface of the

linear guide, and then evenly apply the lubricating oil on the surface

of the linear guide to slide up and down for several times. Meanwhile,

it is possible to add the lubricating oil to the sliding block through its

oil hole;

2) X axis: Remove the X-axis middle baffle plate, wipe clean the

surface of the linear guide, and then evenly apply the lubricating oil

on the surface of the linear guide to slide left and right for several

times. Meanwhile, it is possible to add the lubricating oil to the

sliding block through its oil hole;

3) Y axis: Remove the middle baffle plate and the double-layer carrying

plate on Y axis, wipe clean the surface of the linear guide, and then

evenly apply the lubricating oil on the surface of the linear guide to

slide back and forth for several times. Meanwhile, it is possible to

add the lubricating oil to the sliding block through its oil hole.