- 16 -

Mini Crosser A/S

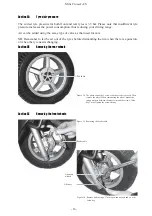

The correct tyre pressure for both front and rear tyres is 3.5 bar. Please note that insuffi cient tyre

pressure increases the power consumption, thus reducing your driving range.

Air can be added using the same type of valve as that used for cars.

NB: Remember to let the air out of the tyres before dismantling the rim when there is a puncture

or when the tyre needs changing.

Section 5B

Removing the rear wheels

Figure 14 The photo shows the 5 screws that have to be removed. Then

remove the wheel. When remounting the wheel, mount the

spring washers between the wheel rim and the screws. Allen

key 5 mm. Tighten the screws fi rmly.

5 screws

Figure 15 Removing the brake cable

Brake cable

Figure 16 Remove bolts using a 17 mm open-end wrench and a 6 mm

Allen

key

Open-end

wrench

Allen key

Section 5C

Removing the front wheels

Section 5A

Tyres/air pressure