39

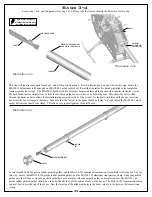

Locate the MA128-187 8mm head axle, four MA0844 90d head damper O-rings, two MA0331 m8x14x0.5 shim washers, two

MA0332 m8x14x1 shim washers, two MA0848-2 m8 retaining clips, two MA0086 m5x12 flanged socket bolts, and the MA0844-9

clip application tool. Refer to

Illustration 6d

for this step. Use retaining clip pliers (snap ring pliers) to install one of the MA0848-2

m8 retaining clips into the groove on the MA128-187 8m head axle. Slip on the MA0332 m8x14x1 shim washer, then the MA0331

m8x14x0.5 shim washer, then two MA0844-6 90d head damper O-rings. Miniature Aircraft USA recommends the use of both

thick and thin shim washers for 3D flying. If you are a beginner, you may choose to omit the use of the MA0331 m8x14x0.5 shim

washers. The result will be a model with a more stable hover and flight characteristic especially at lower head speeds. Slide the

head axle with shims and dampers into the head block. Now slip the other two MA0844-6 90d head damper O-rings, MA0331

m8x14x0.5 shim washer (if you choose to prepare the model for 3D flying), and the MA0332 m8x14x1 shim washer. Thread in (do

not use thread locking compound yet) an MA0086 m5x12 flanged socket bolt into the side of the axle where the MA0848-2 retaining

clip was installed. Slide on the MA0844-9 clip application tool onto the other side of the head axle, and thread in (do not use thread

locking compound yet) the other MA0086 m5x12 flanged socket bolt. Use a 4mm hex driver to hold one of MA0086 m5x12 flanged

socket bolts, and tighten the other until you feel a “click”. The clip application tool presses the MA0848-2 retaining clip into the

groove. After the MA0848-2 m8 retaining clip is seated into the groove, remove the two MA0086 m5x12 flanged socket bolts and

set them aside for the next step.

Locate two MA128-188 main blade grips w/0319 bearings,

two MA128-196 3-D bell mixer assemblies, two MA0112

m3x9.5 threaded control balls, two MA0109 m3x8 threaded

control balls, and two MA0091 m3x16 Phillips bolts.

Refer to

Illustration 6c

for this step. Thread the MA0112

m3x9.5 threaded control balls into the OUTER holes on the

MA128-196 3-D bell mixers. Note there is an inner hole,

for the Fury 55 application we do not recommend installing

the MA0112 m3x9.5 threaded control ball in this location.

Mounting the MA0112 m3x9.5 threaded control ball on the

inner hole on the Fury 55 may result in the binding and/or

failure of the MA0133-1 ball link. Thread the MA0109

m3x8 threaded control balls into the opposite side of each

MA128-196 3-D bell mixer. Slide the MA0091 m3x16

Phillips bolt through each bell mixer, and apply a small

amount of medium CA (cyanoacrylate) to the threads of the

bolt, then thread the bolt into the hole on the blade grip as

shown. It is important to thread the MA0091 Phillips bolts

into the correct hole on the blade grip for proper rotor head

geometry.

USE BoTH WASHERS

foR 3D fLyIng.

oMIT MA0331 foR

BEgInnERS

CA

Illustration 6c

Illustration 6d

128-188

0112

128-196

0091

0109

0848-2 gRoovE foR 0848-2

0332

0331

0844-6

2x

128-187

0844-6

2x

0331

0332

0848-2

0844-9

0086

onE-SIDE CoMPLETE

Summary of Contents for Fury 55 X-CELL

Page 1: ...Assembly instructions Step up to Excellence with X cell...

Page 2: ...2...

Page 30: ...30 Bag 5 Hardware...

Page 43: ...43 Completed Airframe with Electronics Engine and Muffler Installed...

Page 51: ...51 Notes...

Page 52: ...52 Notes...

Page 53: ...53 Notes...

Page 54: ...54 Notes...