18

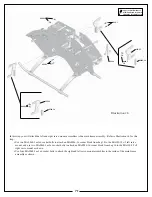

In this step you will install the tail rotor drive pulley into the main frame assembly. Refer to Illustration 1i for this step.

• Insert the MA128-47 t/r drive belt from bag 1c through the aluminum boom clamps, and between the aluminum idler pulleys. Pull

a “loop” of the belt out the right frame side, and position the belt around the MA129-52 54 tooth t/r pulley from bag 1c as shown.

Illustration 1i

129-52

128-47

BELT

NOTE THE ORIENTATION OF

DRIVE BELT IN BETWEEN

THE TWO PULLEYS

Summary of Contents for X-Cell Furion 6

Page 1: ...ASSEMBLY INSTRUCTIONS Step up to Excellence with X cell...

Page 2: ...2...

Page 23: ...Bag 1 Completed Assembly 23...