Revised 04/01/2016

Page 4

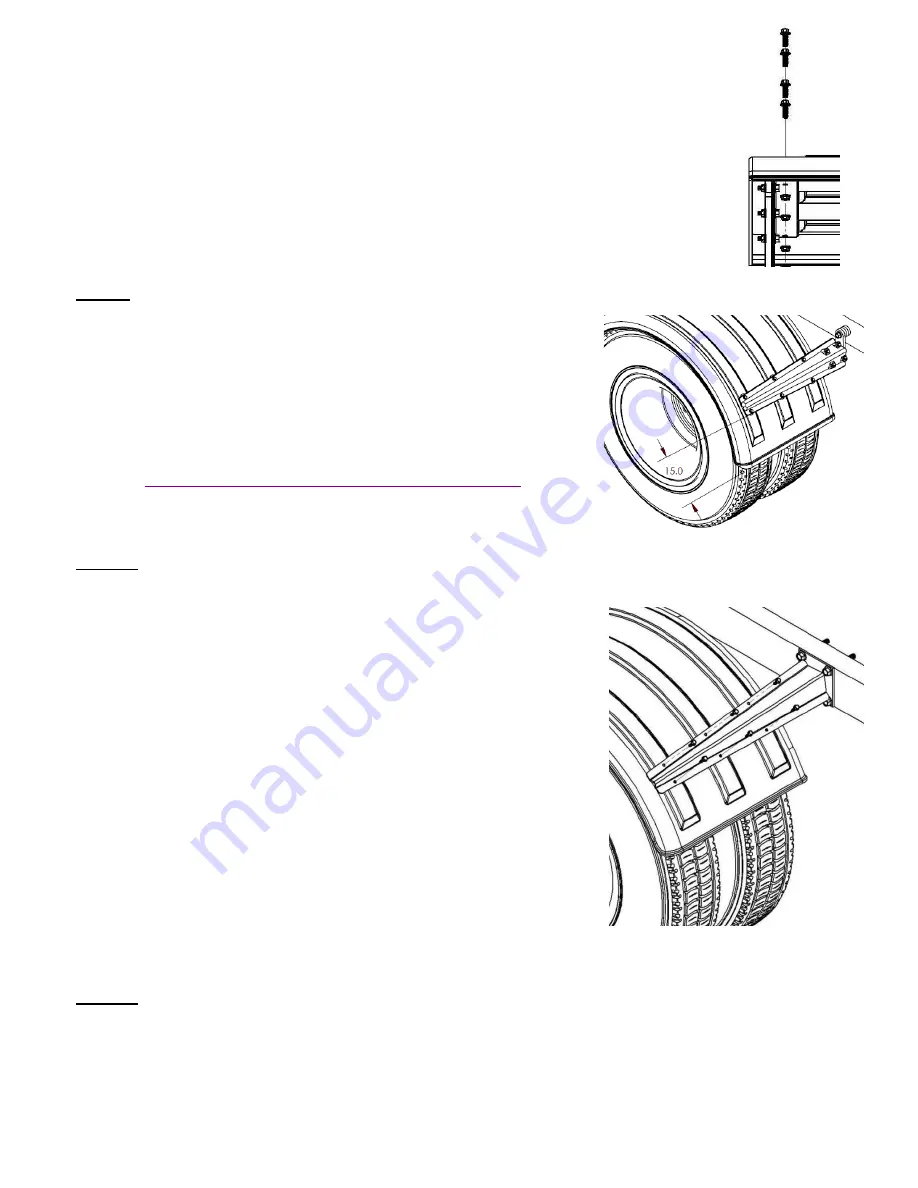

F.

Drill four 5/16” holes through the fender using the holes in bracket PB5071

as a guide (Figure 8).

a.

Install the 5/16” x 1 ¼” bolts through the bracket and into the fender.

d.

Use 5/16” fender washers and 5/16” nuts provided with the kit on

the underside of the fender.

Recommended torque is 10-15 ft-lbs.

Step 4

If possible, position the mounting brackets so they are

located within 15” of the bottom of the fender. This

protects against wind blowing the leading edge of the

fender back into the tire (Figure 9).

Tip:

If the front fender bracket is mounted higher

than 15”, refer

to

http://www.minimizer.com/instructions%20.html

for

further suggestions on adding ad

d

itional support.

STEP 5

A. Attach the bracket (PB5010) to the fender.

a.

Drill six 5/16” holes through the fender using the

holes in bracket PB5010 as a guide.

b.

Install the 5/16” x 1” bolts through the bracket and

into the fender.

c.

Use six 5/16” fender washers and 5/16” nuts

provided with the kit on the underside of the fender.

d.

Tighten the bolts. Recommended torque is 10-

15 ft-lbs.

e. Make sure the fenders are square and aligned

(Figure 10). Twists or

bows in the fender will fatigue the

material over time.

STEP 6

A. For trucks with air suspension, raise and lower the suspension one final time to confirm

that there is adequate clearance between the fenders and wheels.

B. Recheck all brackets and bolts to ensure they are tightened to the recommended torque

Figure 8

Figure 10

Figure 9

Summary of Contents for B4850WOA

Page 5: ...Revised 04 01 2016 Page 5 ...