27

Chapter 4. Safety standards

GB

4.3. Individual protection devices

Wear safety shoes that protect feet from impacts, crushing and compression while moving or handling the

machine.

Wear safety gloves that protect the hands from crushing and mechanical hazards and while moving or

handling the machine.

Wear safety gloves that protect the hands against cutting risks while changing the sealing blades.

Wear safety gloves that protect the hands against the specific risks associated with the materials to be

packed (mechanical, chemical) and against coming into contact with the high temperatures present on the

seals and/or sealing blade (up to 200°C).

Wear safety gloves that prevent the hands from coming into contact with foodstuffs when

packaging them.

Chapter 5. Machine installation

GB

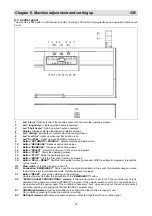

5.1. Transport and positioning

Handle with great care during transport and positioning!

Before any movement, make sure that the lifting means is suitable for the load to be lifted!

Cut the strap with scissors make sure you protect your eyes by wearing glasses and withdraw the cardboard. Remove

the screws and any plate intended to fasten the machine to the pallet.

Lift the machine from the pallet by using a fork lift truck and arrange it on the floor.

For the machine lifting, place the lift truck vanes up to the point stated on the specific label applied

on the machine.

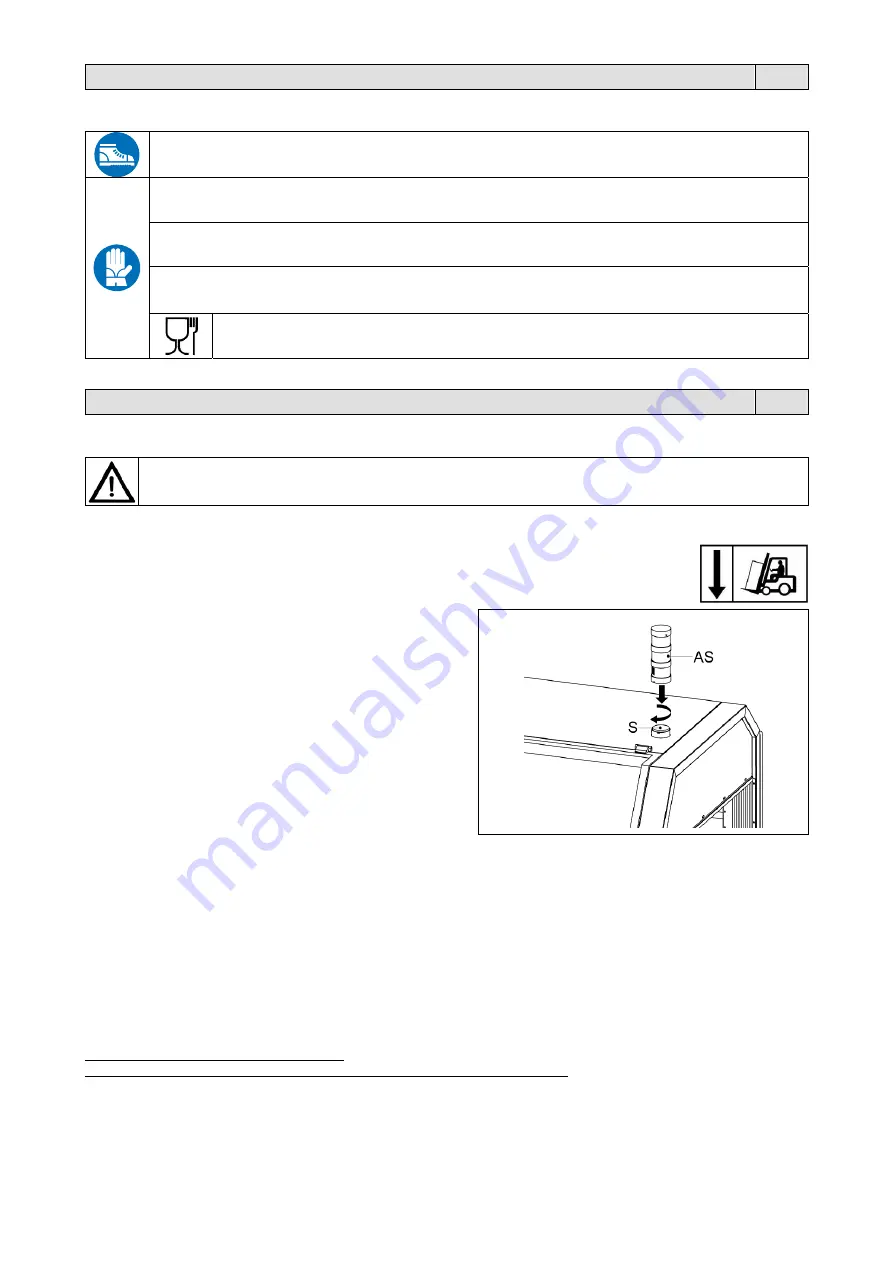

Unpack the siren (AS) and hook it up to the support (S).

5.2. Environmental conditions

Place the machine level on the floor in a suitable environment free from humidity, gases, explosives, combustible

materials. The machine may only be installed on smooth, flat non-inflammable surfaces.

Leave a minimum space of 1m around the machine so that not to obstruct air inlets

Once the correct position is achieved, lock the machine by means of the wheel brakes. If necessary, use the 4 feet

supplied with the machine to ensure that it is locked in position.

Working environment conditions:

Temperature from + 5°C to + 40°C

Relative humidity from 30% to 90%, without condensation.

The lighting of the operation room shall comply with the laws in force in the country where the machine is installed.

However, it shall be uniform and allow good visibility in order to safeguard the operator’s safety and health.

MACHINE PROTECTION FACTOR = IP20

THE AIRBORNE NOISE MADE BY THE MACHINE IS LOWER THAN 70 dB(A)

Summary of Contents for Pratika 56 CS Series

Page 108: ...107 7 4 ...

Page 109: ...108 7 4 ...

Page 110: ...109 7 4 ...

Page 111: ...110 7 4 ...

Page 112: ...111 7 4 ...

Page 113: ...112 7 5 ...

Page 114: ...113 ...